Abstract

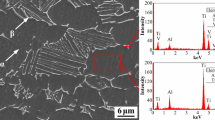

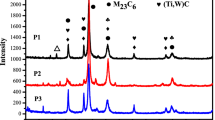

In this study, laser remelting was used to prepare Ta/Ni-based composite coatings using a combination of Ta-doping in a Ni-based powder. The effects of laser remelting specific energy and Ta-doping content on the surface morphology, phase composition, microstructure, bonding interface, microhardness, and wear resistance of the cladding layers were investigated. The unmelted powder particles on the coating surface disappeared after laser remelting. Laser remelting significantly decreased the grain size of the Ta/Ni-based composite coating, and the bright white microstructure of the doped Ta hindered crystal growth. With increase in the specific energy of the remelts, the internal porosity of the coating significantly decreased, overall grain size of the upper part of the composite coating gradually increased, central columnar crystal content gradually increased, overall crystal size of the lower part first decreased and then increased, and Ta and Ni diffused more fully at the bonding interface between the matrix and the coating, which decreased the difference in the chemical composition of the two sides of the bonding interface. The Ta/Ni-based composite remelted layers had significantly improved microhardness and wear resistance compared to before remelting, and both these parameters tended to increase and then decrease with increasing remelting specific energy.

Similar content being viewed by others

References

H. Zheng, M. Cong, D. Liu, H. Dong, and Y. Liu, Int. J. Adv. Manuf. Technol. 100, 599 (2019).

L. Zhu, P. Xue, Q. Lan, G. Meng, Y. Ren, Z. Yang, P. Xu, and Z. Liu, Opt. Laser Technol. 138, 106915 (2021).

G.A. Farotade, A.P.I. Popoola, and S.L. Pityana, Surf. Rev. Lett. 25, 1950005 (2018).

Y. Cai, Z. Luo, M. Feng, Z. Liu, Z. Huang, and Y. Zeng, Surf. Coat. Technol. 291, 222 (2016).

Q. Wang, Q. Li, L. Zhang, D.X. Chen, H. Jin, J.D. Li, J.W. Zhang, and C.Y. Ban, Ceram. Int. 48, 7905 (2022).

Z. Gao, H. Ren, Y. Yuan, Z. Gao, E. Liu, and C. Zhang, Micron 150, 103146 (2021).

R. Li, Z. Li, J. Huang, and Y. Zhu, Appl. Surf. Sci. 258, 7956 (2012).

N.L. Do Vale, C.A. Fernandes, R.A. de Santos, T.F.A. Santos, S.L. Urtiga Filho JOM 73, 2868 (2021).

H. Liu, X. Du, H. Guo, J. Liu, P. Chen, H. Yang, and J. Hao, Optik 228, 166194 (2021).

Y. Jia, W. Sun, and K. Wang, WSRJ 6, 8 (2020).

C. Cui, M. Wu, X. Miao, Y. Gong, and Z. Zhao, J. Mater. Res. Technol. 15, 2405 (2021).

X. Lei, C. Huajun, L. Hailong, and Z. Yubo, Int. J. Adv. Manuf. Technol. 90, 1383 (2017).

F. Weng, C. Chen, and H. Yu, Mater. Des. 58, 412 (2014).

W. Yuan, R. Li, Z. Chen, J. Gu, and Y. Tian, Surf. Coat. Technol. 405, 126582 (2021).

G. Singh, M. Kaur, and R. Upadhyaya, J. Therm. Spray Technol. 28, 1081 (2019).

Y. Cao, N. Farouk, M. Taheri, A.V. Yumashev, S.F.K. Bozorg, and O.O. Ojo, Surf. Coat. Technol. 412, 127010 (2021).

T. Yu, J. Chen, Y. Wen, and Q. Deng, Appl. Surf. Sci. 547, 149171 (2021).

Z. Yu, L. Li, D. Zhang, G. Shi, G. Yang, Z. Xu, and Z. Zhang, Chin. J. Mech. Eng. 34, 92 (2021).

Z. Zhang, Y. Zhao, Y. Chen, Z. Su, J. Shan, A. Wu, Y.S. Sato, H. Gu, and X. Tang, Mater. Des. 198, 109346 (2021).

F. Fu, Y. Zhang, G. Chang, and J. Dai, Optik 127, 200 (2016).

J. Ning, D.E. Sievers, H. Garmestani, and S.Y. Liang, J. Manuf. Process. 49, 135 (2020).

C. Guo, J. Zhou, J. Zhao, L. Wang, Y. Yu, J. Chen, and H. Zhou, Tribol. Lett. 44, 187 (2011).

X. Zhang, X. Cui, G. Jin, Q. Ding, D. Zhang, X. Wen, L. Jiang, S. Wan, and H. Tian, J. Alloys Compd. 891, 161756 (2022).

A. Farnia, F. MalekGhaini, J.C. Rao, V. Ocelík, and J.T.M. De Hosson, Surf. Coat. Technol. 213, 278 (2012).

G. Jiang, C. Cui, L. Chen, Y. Wu, and X. Cui, Materials 14, 7437 (2021).

Z. Shengbin, J. Chenpeng, Y. Yuxue, W. Lixin, H. Yiming, and Y. Lijun, J. Alloys Compd. 908, 164612 (2022).

Y. Zhao, K. Feng, C. Shen, and Z. Li, Mater. Lett. 257, 126614 (2019).

J. Lei, C. Shi, S. Zhou, Z. Gu, and L.-C. Zhang, Surf. Coat. Technol. 334, 274 (2018).

A. Iqbal, G. Zhao, H. Suhaimi, N. He, G. Hussain, and W. Zhao, Int. J. Adv. Manuf. Technol. 111, 2475 (2020).

J.M. Flynn, A. Shokrani, S.T. Newman, and V. Dhokia, Int. J. Mach. Tools Manuf. 101, 79 (2016).

J.L. Dávila, P.I. Neto, P.Y. Noritomi, R.T. Coelho, and J.V.L. da Silva, Int. J. Adv. Manuf. Technol. 110, 3377 (2020).

U.M. Dilberoglu, B. Gharehpapagh, U. Yaman, and M. Dolen, Int. J. Adv. Manuf. Technol. 113, 623 (2021).

G. Zeng, S.H. Zahiri, S. Gulizia, Y. Chen, X.-B. Chen, and I. Cole, J. Mater. Res. 36, 3679 (2021).

L. Li, A. Haghighi, and Y. Yang, J. Manuf. Process. 33, 150 (2018).

Y. Cai, Y. Cui, L. Zhu, R. Tian, K. Geng, H. Li, and J. Han, Surf. Eng. 37, 1496 (2021).

X. Xu, J.L. Du, K.Y. Luo, M.X. Peng, F. Xing, L.J. Wu, and J.Z. Lu, Surf. Coat. Technol. 422, 127500 (2021).

S. Zhou, Y. Xu, B. Liao, Y. Sun, X. Dai, J. Yang, and Z. Li, Opt. Laser Technol. 103, 8 (2018).

D. Cong, H. Zhou, Z. Ren, Z. Zhang, H. Zhang, C. Meng, and C. Wang, Mater. Des. 55, 597 (2014).

B. Das, M. Gopinath, A.K. Nath, and P.P. Bandyopadhyay, Optik 227, 166030 (2021).

B. Xin, X. Zhou, G. Cheng, J. Yao, and Y. Gong, Opt. Laser Technol. 127, 106087 (2020).

Z. Kuai, Z. Li, B. Liu, W. Liu, and S. Yang, Mater. Chem. Phys. 285, 125901 (2022).

H. Wang, Y. Cheng, J. Yang, and Q. Wang, Surf. Coat. Technol. 414, 127081 (2021).

T. Han, Y. Liu, M. Liao, D. Yang, N. Qu, Z. Lai, and J. Zhu, J. Mater. Sci. Technol. 99, 18 (2022).

S. Zhou, J. Lei, X. Dai, J. Guo, Z. Gu, and H. Pan, Int. J. Refract. Met. Hard Mater. 60, 17 (2016).

P. Fan and G. Zhang, Int. J. Refract. Met. Hard Mater. 87, 105133 (2020).

W. Xi, B. Song, Z. Wang, T. Yu, J. Wang, and Y. Dai, Surf. Coat. Technol. 408, 126789 (2021).

K. Wang, D. Du, G. Liu, B. Chang, J. Ju, S. Sun, and H. Fu, J. Alloys Compd. 802, 373 (2019).

D. Shang, J. Zhang, A. Feng, Y. Zhou, J. Tang, and F. Chen, Chin. J. Lasers 47, 0902004 (2020).

Y. Li, S. Dong, S. Yan, X. Liu, E. Li, P. He, and B. Xu, Opt. Laser Technol. 112, 30 (2019).

K. Huo, J. Zhou, F. Dai, and J. Xu, Appl. Surf. Sci. 545, 149078 (2021).

Y. Huang, X. Zeng, Q. Hu, and S. Zhou, Appl. Surf. Sci. 255, 3940 (2009).

Y. Shi, Y. Li, J. Liu, and Z. Yuan, Opt. Laser Technol. 99, 256 (2018).

Y. Jiang, Y. Cheng, X. Zhang, J. Yang, X. Yang, and Z. Cheng, Optik 203, 164044 (2020).

S. Sun, H. Fu, X. Ping, J. Lin, Y. Lei, W. Wu, and J. Zhou, Appl. Surf. Sci. 455, 160 (2018).

T. Yu, Q. Deng, G. Dong, and J. Yang, Appl. Surf. Sci. 257, 5098 (2011).

Q. Xiao, W. Lei Sun, K. Xin Yang, X. Feng Xing, Z. Hao Chen, H. Nan Zhou, and J. Lu, Surf. Coat. Technol. 420, 127341 (2021).

L. Xu, J. Xing, S. Wei, Y. Zhang, and R. Long, Wear 262, 253 (2007).

W. Kaiming, L. Yulong, F. Hanguang, L. Yongping, S. Zhenqing, and M. Pengfei, Surf. Eng. 34, 267 (2018).

Acknowledgements

The authors acknowledge the support to this work from the Key Laboratory Open Fund of Xinjiang Autonomous Region (2020520002), Research and Innovation Project of Xinjiang Autonomous Region (XJ2022G011), the University Science Research Planning Project of Xinjiang Autonomous Region (XJEDU2021Y008), Xinjiang Autonomous Region Fund Project (2021D01C103), and Research Fund of Xinjiang Institute of Engineering (2019xgy152112).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yu, J., Sun, W., Zhang, G. et al. Effect of Variable Specific Energy Laser Remelting on the Morphology, Microstructure, and Mechanical Properties of Ta/Ni-Based Composite Coatings. JOM 75, 4158–4170 (2023). https://doi.org/10.1007/s11837-023-05799-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05799-2