Abstract

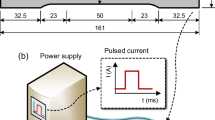

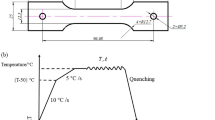

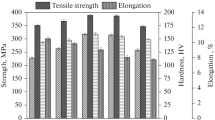

The present study introduces a novel method of high-density pulsed electric current (HDPEC) as a substitute for the conventional annealing heat treatment process to relieve strain hardening in 6061 aluminum alloy (A6061) during the manufacturing process. The study investigates the effects of different HDPEC treatments on the strain-hardening relief of cold-rolled A6061, with a comparison to the traditional annealing heat treatment. The results reveal that the HDPEC-treated samples demonstrate a remarkable reduction of approximately 50% in strength and a considerable increase of approximately 200% in ductility, indicating complete strain-hardening relief of cold-rolled A6061. Consequently, the HDPEC treatment is faster and more efficient than the traditional annealing heat treatment. Furthermore, the HDPEC-treated samples display equivalent mechanical properties as the untreated ones after the final precipitation heat treatment, indicating that the HDPEC treatment has no detrimental effect on the materials. The microstructural characterization demonstrates that the HDPEC-induced microstructural modification through dislocation elimination and grain recovery leads to the strain-hardening relief of cold-rolled A6061. These findings suggest that the HDPEC treatment can even replace the hot-forming process of A6061, contributing to low-cost and high-efficient manufacturing.

Similar content being viewed by others

References

O. Grydin, M. Stolbchenko, F. Nürnberger, and M. Schaper, Influence of Hot Deformation on Mechanical Properties and Microstructure of a Twin-Roll Cast Aluminium Alloy EN AW-6082, J. Mater. Eng. Perform., 2014, 23, p 937–943. https://doi.org/10.1007/s11665-013-0816-4

K. Zhao, R. Fan, and L. Wang, The Effect of Electric Current and Strain Rate on Serrated Flow of Sheet Aluminum Alloy 5754, J. Mater. Eng. Perform., 2016, 25, p 781–789. https://doi.org/10.1007/s11665-016-1913-y

O.A. Troitskii, Electromechanical Effect in Metals, ZhETF Pisma Redaktsiiu., 1969, 10, p 18–22.

Z.S. Xu, Z.H. Lai, and Y.X. Chen, Effect of Electric Current on the Recrystallization Behavior of Cold Worked α—Ti, Scr. Metall., 1988, 22, p 187–190. https://doi.org/10.1016/S0036-9748(88)80331-4

S. Gu, Y. Cui, Y. Kimura, Y. Toku, and Y. Ju, Relief of Strain Hardening in Deformed Inconel 718 by High-Density Pulsed Electric Current, J. Mater. Sci., 2021, 56, p 16686–16696. https://doi.org/10.1007/s10853-021-06344-9

S. Gu, Y. Cui, S. Yoon, Z. Wang, Y. Kimura, Y. Toku, and Y. Ju, Rapid Anisotropy Recovery in Deformed FCC Metals by High-Density Pulsed Electric Current Treatment, Vacuum, 2022, 197, p 110855. https://doi.org/10.1016/j.vacuum.2021.110855

Y.S. Zheng, G.Y. Tang, J. Kuang, and X.P. Zheng, Effect of Electropulse on Solid Solution Treatment of 6061 Aluminum Alloy, J. Alloy. Compd., 2014, 615, p 849–853. https://doi.org/10.1016/j.jallcom.2014.07.062

T.A. Perkins, T.J. Kronenberger, and J.T. Roth, Metallic Forging Using Electrical Flow as an Alternative to Warm/Hot Working, J. Manuf. Sci. Eng., 2007, 129, p 84–94. https://doi.org/10.1115/1.2386164

Y. Jiang, G. Tang, C. Shek, J. Xie, Z. Xu, and Z. Zhang, Mechanism of Electropulsing Induced Recrystallization in a Cold-Rolled Mg-9Al-1Zn Alloy, J. Alloy. Compd., 2012, 536, p 94–105. https://doi.org/10.1016/j.jallcom.2012.05.014

Y. Tang, A. Hosoi, Y. Morita, and Y. Ju, Restoration of Fatigue Damage in Stainless Steel by High-Density Electric Current, Int. J. Fatigue, 2013, 56, p 69–74. https://doi.org/10.1016/j.ijfatigue.2013.08.012

W. Jin, J. Fan, H. Zhang, Y. Liu, H. Dong, and B. Xu, Microstructure, Mechanical Properties and Static Recrystallization Behavior of the Rolled ZK60 Magnesium Alloy Sheets Processed by Electropulsing Treatment, J. Alloy. Compd., 2015, 646, p 1–9. https://doi.org/10.1016/j.jallcom.2015.04.196

H. Conrad, Electroplasticity in Metals and Ceramics, Mater. Sci. Eng. A, 2000, 287, p 276–287. https://doi.org/10.1016/S0921-5093(00)00786-3

C. Zhou, L. Zhan, C. Liu, and M. Huang, Insights into Electron Wind Force by a Helical Dislocation Reconfiguration, IScience., 2023, 26, p 106870. https://doi.org/10.1016/j.isci.2023.106870

C. Rudolf, R. Goswami, W. Kang, and J. Thomas, Effects of Electric Current on the Plastic Deformation Behavior of Pure Copper Iron, and Titanium, Acta Mater., 2021, 209, p 116776. https://doi.org/10.1016/j.actamat.2021.116776

S. Zhao, R. Zhang, Y. Chong, X. Li, A. Abu-Odeh, E. Rothchild, D.C. Chrzan, M. Asta, J.W. Morris, and A.M. Minor, Defect Reconfiguration in a Ti-Al Alloy via Electroplasticity, Nat. Mater., 2020 https://doi.org/10.1038/s41563-020-00817-z

K. Jeong, S.W. Jin, S.G. Kang, J.W. Park, H.J. Jeong, S.T. Hong, S.H. Cho, M.J. Kim, and H.N. Han, Athermally Enhanced Recrystallization Kinetics of Ultra-Low Carbon Steel via Electric Current Treatment, Acta Mater., 2022, 232, p 117925. https://doi.org/10.1016/j.actamat.2022.117925

M.J. Kim, S. Yoon, S. Park, H.J. Jeong, J.W. Park, K. Kim, J. Jo, T. Heo, S.T. Hong, S.H. Cho, Y.K. Kwon, I.S. Choi, M. Kim, and H.N. Han, Elucidating the Origin of Electroplasticity in Metallic Materials, Appl. Mater. Today., 2020, 21, p 100874. https://doi.org/10.1016/j.apmt.2020.100874

S. Birinci, S. Basit, and N. Maraşlı, Influences of Directions and Magnitudes of Static Electrical Field on Microstructure and Mechanical Properties for Al-Si Eutectic Alloy, J. Mater. Eng. Perform., 2022, 6, p 5070–5079. https://doi.org/10.1007/s11665-021-06564-9

W. Zhang, M.L. Sui, Y.Z. Zhou, and D.X. Li, Evolution of Microstructures in Materials Induced by Electropulsing, Micron, 2003, 34, p 189–198. https://doi.org/10.1016/S0968-4328(03)00025-8

T. Shintani and Y. Murata, Evaluation of the Dislocation Density and Dislocation Character in Cold Rolled Type 304 Steel Determined by Profile Analysis of x-ray Diffraction, Acta Mater., 2011, 59, p 4314–4322. https://doi.org/10.1016/j.actamat.2011.03.055

T. Ungár, I. Dragomir, Á. Révész, and A. Borbély, The Contrast Factors of Dislocations in Cubic Crystals: the Dislocation Model of Strain Anisotropy in Practice, J. Appl. Crystallogr., 1999, 32, p 992–1002. https://doi.org/10.1107/S0021889899009334

M. Jamal, S.J. Asadabadi, I. Ahmad, and H.R. Aliabad, Elastic Constants of Cubic Crystals, Comput. Mater. Sci., 2014, 95(592), p 9. https://doi.org/10.1016/j.commatsci.2014.08.027

Y. Zhang, J.P. Liu, S.Y. Chen, X. Xie, P.K. Liaw, K.A. Dahmen, J.W. Qiao, and Y.L. Wang, Serration and Noise Behaviors in Materials, Prog. Mater Sci., 2017, 90, p 358–460. https://doi.org/10.1016/j.pmatsci.2017.06.004

Z. Sajuri, N.F. Mohamad Selamat, A.H. Baghdadi, A. Rajabi, M.Z. Omar, A.H. Kokabi, and J. Syarif, Cold-Rolling Strain Hardening Effect on the Microstructure, Serration-Flow Behaviour and Dislocation Density of Friction Stir Welded AA5083, Metals., 2020, 10, p 70. https://doi.org/10.3390/met10010070

G.I. Taylor, The mechanism of plastic deformation of crystals Part I Theoretical, Proc. R. Soc. Lond. Ser. A Contain. Pap. Math. Phys. Character, 1934, 145(855), p 362–387.

P. Rodriguez, Sixty Years of Dislocations, Bull. Mater. Sci., 1996, 19, p 857–872. https://doi.org/10.1007/BF02744623

E.O. Hall, The deformation and ageing of mild steel: III discussion of results, Proc. Phys. Soc. Sect. B., 1951, 64(9), p 747. https://doi.org/10.1088/0370-1301/64/9/303

N.J. Petch, The Cleavage Strength of Polycrystals, J. Iron Steel Inst., 1953, 174, p 25.

H. Conrad, A.F. Sprecher, The Electroplastic Effect in Metals, in: Dislocations in Solids, Elsevier, 497–541 (1989)

F.R.N. Nabarro, Theory of Crystal Dislocations, Clarendon Press, Oxford, 1967.

R.A. Brown, Electrical resistivity of dislocations in metals, J. Phys. F Met. Phys., 1977, 7, p 1283–1295. https://doi.org/10.1088/0305-4608/7/7/026

R. Peierls, The Size of a Dislocation, Proc. Phys. Soc., 1940, 52, p 34. https://doi.org/10.1088/0959-5309/52/1/305

F.R.N. Nabarro, Dislocations in a Simple Cubic Lattice, Proc. Phys. Soc., 1947, 59, p 256. https://doi.org/10.1088/0959-5309/59/2/309

T. Suzuki and S. Takeuchi, Correlation of Peierls-Nabarro Stress with Crystal Structure, Rev. Phys. Appl. Paris, 1988, 23, p 685–685. https://doi.org/10.1051/rphysap:01988002304068500

Y. Kamimura, K. Edagawa, and S. Takeuchi, Experimental Evaluation of the Peierls Stresses in a Variety of Crystals and their Relation to the Crystal Structure, Acta Mater., 2013, 61, p 294–309. https://doi.org/10.1016/j.actamat.2012.09.059

M. Janovská, H. Seiner, J. CIŽEK, P. Sedlák, and M. LAND, Evolution of Elastic Properties of Cold Sprayed Metal Coatings at Elevated Temperatures, Acta Phys, Pol. A., 2018, 134, p 794–798. https://doi.org/10.12693/APhysPolA.134.794

Acknowledgments

This work was supported by JSPS KAKENHI Grant-in-Aid for Challenging Research (Pioneering) 20K20531. The authors are also very grateful to Kobe Steel Ltd. and UACJ corporation for providing cold-rolled aluminum alloy sheets.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xiaoming, Y., Shaojie, G., Sungmin, Y. et al. Annealing Effect of High-Density Pulsed Electric Current Treatment on Cold-Rolled 6061 Aluminum Alloy. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08522-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08522-z