Abstract

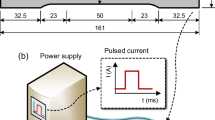

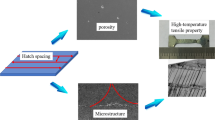

The effect of high-density pulsed electric current (HDPEC) on the microstructure evolution and corresponding changes in the mechanical properties of the deformed Ni-based alloy Inconel 718 was investigated. After HDPEC treatment, the strain hardening was fully relieved and the ductility recovered correspondingly. The results show that the dislocation density plays a dominant role, and the grain size has a side effect on the strain-hardening relief. Furthermore, the correlation between the mechanical properties and microstructure evolution affected by HDPEC was clarified. HDPEC treatment provides a way to alter the microstructure and thus tailor the mechanical properties of the deformed components. Hence, it is applicable to the metal-forming field to achieve rapid relief of strain hardening and enhance formability.

Graphical abstract

Similar content being viewed by others

References

Black JT, Kohser RA, DeGarmo EP (2012) DeGarmo’s materials and processes in manufacturing, 11th edn. Wiley, Hoboken

Hull D, Bacon DJ (2011) Introduction to dislocations, 5th edn. Elsevier/Butterworth-Heinemann, Amsterdam

Rollett A, Humphreys FJ, Rohrer GS, Hatherly M (2004) Recrystallization and Related Annealing Phenomena, 2nd edn. Pergamon, Amsterdam, Boston

Pan L, Wang B, Xu Z (2019) Effects of electropulsing treatment on residual stresses of high elastic cobalt-base alloy ISO 5832–7. J Alloy Compd 792:994–999. https://doi.org/10.1016/j.jallcom.2019.04.091

Tang Y, Hosoi A, Morita Y, Ju Y (2013) Restoration of fatigue damage in stainless steel by high-density electric current. Int J Fatigue 56:69–74. https://doi.org/10.1016/j.ijfatigue.2013.08.012

Jiang Y, Tang G, Shek C et al (2012) Mechanism of electropulsing induced recrystallization in a cold-rolled Mg–9Al–1Zn alloy. J Alloy Compd 536:94–105. https://doi.org/10.1016/j.jallcom.2012.05.014

Jin W, Fan J, Zhang H et al (2015) Microstructure, mechanical properties and static recrystallization behavior of the rolled ZK60 magnesium alloy sheets processed by electropulsing treatment. J Alloy Compd 646:1–9. https://doi.org/10.1016/j.jallcom.2015.04.196

Zhu R, Jiang Y, Guan L et al (2016) Difference in recrystallization between electropulsing-treated and furnace-treated NiTi alloy. J Alloy Compd 658:548–554. https://doi.org/10.1016/j.jallcom.2015.10.239

Park J-W, Jeong H-J, Jin S-W et al (2017) Effect of electric current on recrystallization kinetics in interstitial free steel and AZ31 magnesium alloy. Mater Charact 133:70–76. https://doi.org/10.1016/j.matchar.2017.09.021

Jeong H-J, Kim M-J, Choi S-J et al (2020) Microstructure reset-based self-healing method using sub-second electric pulsing for metallic materials. Appl Mater Today 20:100755. https://doi.org/10.1016/j.apmt.2020.100755

Eigenmann B, Macherauch E (1996) Röntgenographische Untersuchung von Spannungszuständen in Werkstoffen. Teil III. Fortsetzung von Matwiss. und Werkstofftechn. Heft 3/1995, S. 148–160 und Heft 4/1995, S. 199–216. Mat-wiss u Werkstofftech 27:426–437. https://doi.org/10.1002/mawe.19960270907

Eigenmann B, Macherauch E (1996) Röntgenographische Untersuchung von Spannungszuständen in Werkstoffen Teil IV. Fortsetzung von Matwiss. und Werkstofftechn. Heft 3/1995, S. 148–160, Heft 4/1995, S. 199–216 und Heft 9/1996, S. 426–437. Mat-wiss u Werkstofftech 27:491–501. https://doi.org/10.1002/mawe.19960271010

Ungár T, Ott S, Sanders PG et al (1998) Dislocations, grain size and planar faults in nanostructured copper determined by high resolution X-ray diffraction and a new procedure of peak profile analysis. Acta Mater 46:3693–3699. https://doi.org/10.1016/S1359-6454(98)00001-9

Ungár T, Dragomir I, Révész Á, Borbély A (1999) The contrast factors of dislocations in cubic crystals: the dislocation model of strain anisotropy in practice. J Appl Crystallogr 32:992–1002. https://doi.org/10.1107/S0021889899009334

Shintani T, Murata Y (2011) Evaluation of the dislocation density and dislocation character in cold rolled Type 304 steel determined by profile analysis of X-ray diffraction. Acta Mater 59:4314–4322. https://doi.org/10.1016/j.actamat.2011.03.055

Hielscher R, Schaeben H (2008) A novel pole figure inversion method: specification of the MTEX algorithm. J Appl Crystallogr 41:1024–1037. https://doi.org/10.1107/S0021889808030112

Weibull W (1951) A Statistical Distribution Function of Wide Applicability. Journal of Applied Mechanics 293–297

Kamaya M, Wilkinson AJ, Titchmarsh JM (2005) Measurement of plastic strain of polycrystalline material by electron backscatter diffraction. Nucl Eng Des 235:713–725. https://doi.org/10.1016/j.nucengdes.2004.11.006

Brewer LN, Othon MA, Young LM, Angeliu TM (2006) Misorientation mapping for visualization of plastic deformation via electron back-scattered diffraction. Microsc Microanal 12:85–91. https://doi.org/10.1017/S1431927606060120

Taylor GI (1934) The mechanism of plastic deformation of crystals. Part I. —Theoretical. Proc Royal Soc Lond Ser A Contain Papers Math Phys Character 145:362–387. https://doi.org/10.1098/rspa.1934.0106

Pelleg J (2013) Mechanical Properties of Materials. Springer, Berlin

Courtney TH (2005) Mechanical Behavior of Materials: Second Edition. Waveland Press

Qin W, Li J, Liu Y et al (2019) Effects of grain size on tensile property and fracture morphology of 316L stainless steel. Mater Lett 254:116–119. https://doi.org/10.1016/j.matlet.2019.07.058

Sylwestrowicz W, Hall EO (1951) The deformation and ageing of mild steel. Proc Phys Soc B 64:495–502. https://doi.org/10.1088/0370-1301/64/6/305

Rodriguez P (1996) Sixty years of dislocations. Bull Mater Sci 19:857–872. https://doi.org/10.1007/BF02744623

Davoudi KM, Vlassak JJ (2018) Dislocation evolution during plastic deformation: Equations vs. discrete dislocation dynamics study. Journal of Applied Physics 123:085302. https://doi.org/10.1063/1.5013213

Pei C, Shi D, Yuan H, Li H (2019) Assessment of mechanical properties and fatigue performance of a selective laser melted nickel-base superalloy Inconel 718. Mater Sci Eng, A 759:278–287. https://doi.org/10.1016/j.msea.2019.05.007

Withers PJ, Bhadeshia HKDH (2001) Residual stress. Part 1 – Measurement techniques. Mater Sci Technol 17:355–365. https://doi.org/10.1179/026708301101509980

Withers PJ, Bhadeshia HKDH (2001) Residual stress. Part 2 – Nature and origins. Mater Sci Technol 17:366–375. https://doi.org/10.1179/026708301101510087

Askeland DR, Fulay PP (2009) Essentials of materials science and engineering, 2nd ed. Cengage Learning, Australia; United States

Huntington HB, Grone AR (1961) Current-induced marker motion in gold wires. J Phys Chem Solids 20:76–87. https://doi.org/10.1016/0022-3697(61)90138-X

Conrad H (2000) Electroplasticity in metals and ceramics. Mater Sci Eng, A 287:276–287. https://doi.org/10.1016/S0921-5093(00)00786-3

Xiang S, Zhang X (2019) Dislocation structure evolution under electroplastic effect. Mater Sci Eng, A 761:138026. https://doi.org/10.1016/j.msea.2019.138026

Tang Y, Hosoi A, Iwase Y, Ju Y (2013) Effect of high-density electric current on the microstructure and fatigue crack initiation of stainless steel. Mater Trans 54:2085–2092. https://doi.org/10.2320/matertrans.M2013198

Yuichi I (2014) The effect of high-density electric current on dislocation annihilation and fatigue crack initiation of metallic material. Master thesis, Nagoya University

Moussa C, Bernacki M, Besnard R, Bozzolo N (2015) About quantitative EBSD analysis of deformation and recovery substructures in pure Tantalum. IOP Conf Ser: Mater Sci Eng 89:012038. https://doi.org/10.1088/1757-899X/89/1/012038

Song H, Wang Z-J (2008) Microcrack healing and local recrystallization in pre-deformed sheet by high density electropulsing. Mater Sci Eng, A 490:1–6. https://doi.org/10.1016/j.msea.2007.12.037

Song H, Wang Z, He X, Duan J (2017) Self-healing of damage inside metals triggered by electropulsing stimuli. Sci Rep 7:7097. https://doi.org/10.1038/s41598-017-06635-9

Yang CL, Yang HJ, Zhang ZJ, Zhang ZF (2018) Recovery of tensile properties of twinning-induced plasticity steel via electropulsing induced void healing. Scripta Mater 147:88–92. https://doi.org/10.1016/j.scriptamat.2018.01.008

Chen Z, Butcher C (2013) Introduction to Ductile Fracture Modelling. In: Chen Z, Butcher C (eds) Micromechanics Modelling of Ductile Fracture. Springer, Netherlands, Dordrecht, pp 1–24

Lubarda VA, Schneider MS, Kalantar DH et al (2004) Void growth by dislocation emission. Acta Mater 52:1397–1408. https://doi.org/10.1016/j.actamat.2003.11.022

Acknowledgements

The authors are grateful to the JSPS KAKENHI Grant-in-Aid for Scientific Research (S) 17H06146 for providing financial support for this study.

Author information

Authors and Affiliations

Contributions

Shaojie Gu contributed to the conceptualization, investigation, data curation, formal analysis, and writing of the original draft. Yi Cui helped in the validation, investigation, and writing—review and editing. Yasuhiro Kimura was involved in the data curation and writing—review and editing. Yuhki Toku helped in the validation and writing—review and editing. Yang Ju contributed to the conceptualization, methodology, supervision, project administration, resources, and writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Handling Editor: Sophie Primig.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gu, S., Cui, Y., Kimura, Y. et al. Relief of strain hardening in deformed Inconel 718 by high-density pulsed electric current. J Mater Sci 56, 16686–16696 (2021). https://doi.org/10.1007/s10853-021-06344-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06344-9