Abstract

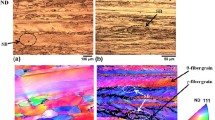

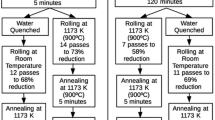

The static recrystallization behaviour and microstructure evolution of cold rolled (CR) Ti-B20 alloy with high strength during annealing were investigated using electron back-scattered diffraction and x-ray diffraction methods. Results suggest that the deformation bands and grain boundaries in the CR Ti-B20 alloy became a preferred nucleation position of recrystallized grains, which led to the formation of an uneven microstructure at the initial stage of annealing. After a given annealing time, the nucleation and growth rate of recrystallized grains accelerated with increasing annealing temperature. The relationship among the volume fraction of recrystallized grains, annealing temperature and annealing time can be described by the Johnson–Mehl–Avrami–Kolmogorov equations \(\left( {X_{800} = 1 - \exp ( - {0}{\text{.00011}}\, * \,t^{1.64} } \right)\) and \(X_{820} = 1 - \exp ( - {0}{\text{.00009}}\, * \,t^{1.98} )\). For the CR sheet specimens, a typical cold texture was formed, such as γ-fiber components of {111} < 110 > and {111} < 112 > textures. When complete recrystallization occurs for the CR sheet, the texture component primarily consists of {112} < 021 > for the CR sheet annealed at 800 and 820 °C.

Similar content being viewed by others

References

A. Devaraj, V.V. Joshi, A. Srivastava et al., A Low-Cost Hierarchical Nanostructured Beta-Titanium Alloy with High Strength, Nat. Commun., 2016, 7(11176), p 1–9.

Q.M. Liu, Z.H. Zhang, S.F. Liu et al., Application and Development of Titanium Alloy Inaerospace and Military Hardware, J. Iron. Steel. Res. Int., 2015, 29(29), p 4–10.

X. Xu, L.M. Dong, H.B. Ba et al., Hot Deformation Behavior and Microstructural Evolution of Beta C Titanium Alloy in β Phase Field, Trans. Nonferrous. Met. Soc. China., 2016, 26(11), p 2874–2882.

C.W. Huang, Y.Q. Zhao, S.W. Xin et al., Effect of Microstructure on High Cycle Fatigue Behavior of Ti–5Al–5Mo–5V–3Cr–1Zr Titanium Alloy, Int. J. Fatigue., 2017, 94, p 30–40.

Z. Hu, D. Yi, H. Liu et al., New Type of Macrozone in a Near-β Titanium Alloy Ti-5Al-5Mo-5V-1Cr-1Fe, Mater. Let., 2019, 238, p 6–9.

D. Chalapathi, P.V. Sivaprasad, and A.K. Kanjarla, Role of Deformation Twinning and Second Phase on the Texture Evolution in a Duplex Stainless Steel During Cold Rolling: Experimental and Modelling Study, Mater. Sci. Eng. A, 2020, 780, p 139155.

B. Dwa, B. Qfa, A. Xc et al., Texture Evolution and Slip Mode of a Ti-5.5Mo-7.2Al-4.5Zr-2.6Sn-2.1Cr Dual-Phase Alloy During Cold Rolling Based on Multiscale Crystal Plasticity Finite Element Model, J. Mate. Sci. Technol., 2021, 111, p 76–87.

Y.C. Chen, S.W. Wang et al., Effect of Cold Rolling on Structure and Tensile Properties of cast Ti-7.5Mo Alloy, Mater. Sci. Eng. A., 2015, 631, p 52–66.

Z. Zhang, W. Wan, J. Cao et al., Effect of Cold Deformation on Microstructure and Mechanical Properties of Ti13Nb13Zr Titanium Alloy, Hot Work Technol, 2009, 38(22), p 66–81.

T.W. Xu, J.S. Li, S.S. Zhang et al., Cold Deformation Behavior of the Ti-15Mo-3Al-2.7Nb-0.2Si Alloy and Its Effect on Alpha Precipitation and Tensile Properties in Aging Treatment, J. Alloys. Compd., 2016, 682, p 404–411.

A.M. Ferreira, M.A. Martorano, N.D. Lima et al., Effects of Recovery and Recrystallization on Microstructure and Texture During Annealing of a Cold Deformed Superconducting Nb-50(wt.)%Ti Alloy, J. Alloys. Compd., 2021, 887, p 887–899.

C. Lan, Y. Wu, L.L. Guo et al., Microstructure, Texture Evolution and Mechanical Properties of Cold Rolled Ti-32.5Nb-6.8Zr-2.7Sn Biomedical Beta Titanium Alloy, J. Mater. Eng. Technol., 2018, 34, p 788–792.

S. Guo, Q.K. Meng, X.N. Cheng et al., Microstructural Evolution and Mechanical Behavior of Metastable β-type Ti-30Nb-1Mo-4Sn Alloy with Low Modulus and High Strengt, Prog. Nat. Sci., 2015, 25(05), p 414–418.

X.D. Huo, X.P. Mao, S.X. Liu et al., Effect of Annealing Temperature on Recrystallization Behavior of Cold Rolled Ti-Microalloyed Steel, J. Iron. Steel. Res. Int., 2013, 20(9), p 105–110.

C. Lan, W. Yu, and L. Guo, Effects of Cold Rolling on Microstructure, Texture Evolution and Mechanical Properties of Ti-32.5Nb-6.8Zr-2.7Sn-0.30 Alloy for Biomedical Applications, Mater. Sci. Eng. A., 2017, 690, p 170–176.

S.J. Dai, Y. Wan, and F. Chen, Effects of Annealing on the Microstructures and Mechanical Properties of Biomedical Cold-Rolled Ti-Nb-Zr-Mo-Sn alloy, Mate. Charact., 2015, 104, p 15–22.

Q.K. Meng, Y.F. Huo, W. Ma et al., Design and Fabrication of a Low Modulus β-type Ti-Nb-Zr Alloy by Controlling Martensitic Transformation, Rare Met., 2018, 37(9), p 789–796.

Y. Wen, Y.F. Wang, H. Ran et al., Improving the Mechanical and Tribological Properties of NiTi Alloys by Combining Cryo-Rolling and Post-Annealing, Acta. Metall. Sinica., 2022, 35(2), p 317–325.

S. Ozan, J. Lin, Y. Zhang et al., Cold Rolling Deformation and Annealing Behavior of a β-type Ti-34Nb-25Zr Titanium Alloy for Biomedical Applications, J. Mater. Eng. Technol., 2019, 9(2), p 2308–2318.

P.K. Rai, D. Naidu, S.K. Vajpa et al., Effect of Cold Rolling and Heat Treatment on Corrosion and Wear Behavior of β-Titanium Ti-25Nb-25Zr Alloy, J. Mater. Eng. Perform., 2021, 30(6), p 4174–4182.

S.Y. Lu, F.C. Ma, P. Liu et al., Recrystallization Behavior and Super-Elasticity of a Metastable β-Type Ti-21Nb-7Mo-4Sn Alloy During Cold Rolling and Annealing, J. Mater. Eng. Perform., 2018, 27(8), p 3174–3183.

A. Gupta, R.K. Khatirkar, and T. Dandekar, Recrystallization Behavior of a Cold Rolled Ti-15V-3Sn-3Cr-3Al Alloy, J. Mate. Res., 2019, 225, p 1–11.

H. Wang, B.L. Wu, X.H. Du, and Q.G. Xu, Recrystallization Texture of Ti-15–3Alloy with Different Heat Treatments, Mater. Mech. Eng., 2008, 11, p 20–24.

P. Ge, Y.Q. Zhao, and L. Zhou, A New Type Metastable β Titanium Alloy Ti-B20 with High Strength, Rare. Met. Mater. Eng., 2005, 05, p 790–794.

P.P. Ge, S. Xiang, Y.B. Tan et al., Studies on the β→α Phase Transition Kinetics of Ti-3.5Al-5Mo-4V Alloy under Isothermal Conditions by X-ray Diffraction, Metals, 2020, 10(1), p 90.

S. Hu, Y.B. Tan, W. Shi et al., Microstructure, Texture Evolution and Mechanical Behavior of Ti-35Al-5Mo-4V Titanium Alloy During Hot Rolling in a β Field, Mater. Today Commun., 2022, 31, p 103506.

S. Hu, S. Xiang, Y.B. Tan et al., Synchronous Enhancement of the Strength and Ductility in a Metastable β-Ti Alloy by a New Refined α Phase Mechanism, J. Alloys. Compd., 2022, 922, p 166227.

Q. Ran, S. Xiang, Y.B. Tan et al., Improving Mechanical Properties of GH4169 Alloys by Reversing the Deformation and Aging Sequence, Ad. Eng. Mater., 2021, 2100386, p 1–9.

X.M. Ji, P.P. Ge, S. Xiang et al., Effects of Double-Ageing Heat Treatments on the Microstructure and Mechanical Behaviour of a Ti-3.5Al-5Mo-4V Alloy, Mater., 2021, 14(1), p 209.

A. Ag, A. Rk, and B. Js, A Review of Microstructure and Texture Evolution during Plastic Deformation and Heat Treatment of β-Ti alloys, J. Alloys. Compd., 2022, 899, p 899–912.

X.P. Liang, Q.B. Wu, H.Z. Li et al., Static Recrystallization and Texture Evolution of Cold-Rolled Powder Metallurgy CoCrFeNiN0.07 High-Entropy Alloy, J. Alloy. Compd., 2021, 862, p 158602.

Z. Du, Y. Ma, F. Liu et al., The Influences of Process Annealing Temperature on Microstructure and Mechanical Properties of near β High Strength Titanium Alloy Sheet, Materials, 2019, 12(9), p 1478.

Z.F. Qi, Diffusion and Phase Transition in Solid Metals, China Machine Press, 1998, 20–63

X.Y. Zheng, W.B. Xie, L.F. Zeng et al., Achieving High Strength and Ductility in a Heterogeneous-Grain-Structured CrCoNi Alloy Processed by Cryorolling and Subsequent Short-Annealing, Mater. Sci. Eng. A., 2021, 821, p 141610.

S. Ozan, J. Lin, Y. Li et al., Deformation Mechanism and Mechanical Properties of a Thermomechanically Processed β Ti–28Nb–35.4Zr alloy, J. Mech. Behav. Biomed., 2018, 78, p 224–234.

H.Z. Guo, H.Q. Liang et al., The Construction of Constitutive Model and Identification of Dynamic Softening Mechanism of High-Temperature Deformation of Ti-5Al-5Mo-5V-1Cr-1Fe Alloy, Mater. Sci. Eng. A., 2014, 615, p 42–50.

D.G. Lee, C. Li, Y. Lee et al., Effect of Temperature on Grain Growth Kinetics of High Strength Ti–2Al–9.2Mo–2Fe Alloy, Thermochim. Acta, 2014, 586, p 66–71.

C. Wu, S. Huang et al., Microstructure Tailoring and Impact Toughness of a Newly Developed High Strength Ti-5Al-3Mo-3V-2Cr-2Zr-1Nb-1Fe Alloy, Mater. Charact., 2021, 175, p 111103.

V.D. Cojocaru, D. Raducanu et al., Effects of Cold-Rolling Deformation on Texture Evolution and Mechanical Properties of Ti–29Nb–9Ta–10Zr Alloy, Mater Sci Eng. A, 2013, 586(6), p 1–10.

W.A. Johnson, R.F. Mehl, A. Member, Reaction Kinetics in Processes of Nucleation and Growth, Metall. Mater. Tran. A., 2010(11).

T. Furu, Marthinsen, Modelling Recrystallisation, Mater. Sci. Technol., 1990, 66(11), p 1093–1102.

Y.S. Seo, Y.B. Chun, and S.K. Hwang, A 3D Monte-Carlo Simulation Study of Recrystallization Kinetics in Zr with Hypothetical Stored Energy Gradients, Comput. Mater. Sci., 2008, 43, p 512–521.

S.A. Mantri, D. Choudhuri, T. Alam et al., Tuning the Scale of Alpha Precipitates in Beta-Titanium Alloys for Achieving High Strength, Scr. Mater., 2018, 154, p 139–144.

T.Y. Li , F.R. Chen, Z.H. Zhang, Effect of Welding Speed on Microstructure and Mechanical Properties of 7A52 Aluminum Alloy by Friction Stir Welding, J. Netshape Form. Eng., 2015

Y. Yu, R. Chen, C.Y. Li et al., A Study on Microstructural Evolution and Detwinning Behavior of Ti-3Al-25V Cold-Rolled Tube During Annealing, Mater. Res. Express., 2020, 7(9), p 096520.

Acknowledgements

This research was funded by the National Natural Science Foundation of China (Grant Nos. 51974097, and 52161010), the Program of “One Hundred Talented People” of Guizhou Province (Grant No. 20164014), Guizhou Province Science and Technology Project (Grant Nos. 20191414 and 2022050), Breeding programs of Guizhou University (Grant No. 202021).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ji, X., Xiang, S., Zeng, M. et al. Effects of Recrystallization on the Microstructure and Mechanical Properties of Cold-Rolled Ti-B20 Alloy. J. of Materi Eng and Perform 33, 854–863 (2024). https://doi.org/10.1007/s11665-023-08028-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08028-8