Abstract

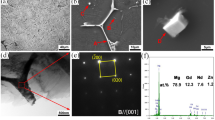

High strength and large ductility of existing Mn-containing brass alloys need to be further improved when used as slippers of friction-pair materials, which could be achieved by tuning alloy composition and thermomechanical treatments appropriately. The present work optimized the amount of minor-alloying elements M (M = Mn, Fe, Si) in Cu-Zn alloy via a cluster formula approach and then investigated the microstructural evolution of the designed alloy with different thermomechanical treatments. As-cast alloy ingots were solid-solutioned at 1093 K (820 °C) for 3 h, hot-rolled at 923 ~ 1023 K (650 ~ 750 °C), and then aged at 673 ~ 723 K (400 ~ 450 °C) for 1 ~ 2 h, respectively. It is found that the alloy matrix consists of the main FCC-α phase plus a small amount of BCC-β and M5Si3 phases, among which the M5Si3 exhibits three types of primary, fine, and nano-scaled particles. The mechanical property varies with the thermomechanical treatments due to diverse microstructures (especially the morphology of M5Si3 particles), in which the high strength (σUTS > 580 MPa) and large ductility (δ = 16.3 ~ 29.4%) could be achieved simultaneously in 673 K (400 °C). The optimal matching of high strength and large ductility makes the current alloy more suitable as an alternative slipper material. The strengthening effect was further discussed in light of various strengthening mechanisms, and the calculated strength increment is well consistent with the experimentally measured yield strength.

Similar content being viewed by others

References

M. Alizadeh and M. Avazzadeh, Evaluation of Cu-26Zn-5Al Shape Memory Alloy Fabricated by Accumulative Roll Bonding Process, Mater. Sci. Eng. A, 2019, 757, p 88–94.

P.F. Wang, J.C. Jie, X.L. Sun, W.G. Liu and T.J. Li, Simultaneous Achievement of High Strength and Superior Ductility in an As-Rolled Cu-30Zn Brass, J. Mater. Eng. Perform., 2019, 28, p 7782–7788.

T.J. Li, Y.Q. Wang, M. Yang, H.L. Hou and S.J. Wu, High Strength and Conductivity Copper Matrix Composites Reinforced by In-situ Graphene Through Severe Plastic Deformation Processes, J. Alloys Compd., 2021, 851, p 156703.

S.F. Li, H. Imai, H. Atsumi and K. Kondoh, An Investigation of Microstructure and Phase Transformation Behavior of Cu40Zn-1.0 wt.% Ti Brass Via Powder Metallurgy, J. Mater. Eng. Perform., 2013, 22, p 3168–3174.

G. Haidak, D. Wang, S.J. E and F.Y. Li, (2019) The Impact of the Deformation Phenomenon on the Process of Lubricating and Improving the Efficiency Between the Slipper and Swashplate in Axial Piston Machines, IEEE Access, 7, p 69393-69409

J. Ma, J. Chen, J. Li, Q. Li and C. Ren, Wear Analysis of Swash plate/slipper Pair of Axis Piston Hydraulic Pump, Tribol. Int., 2015, 90, p 90467–90472.

B. Xu, J.H. Zhang and Y.H. Yang, Investigation on Structural Optimization of Anti-overturning Slipper of Axial Piston Pump, Sci. China Technol. Sci., 2012, 55(11), p 3010–3018.

M.H. Wang, K. Wei, X.J. Li and A.Z. Tu, Constitutive Modeling for High Temperature Flow Behavior of a High-Strength Manganese Brass, J. Cent. South Univ., 2018, 25(7), p 1560–1572.

Y.S. Sun, G.W. Lorimer and N. Ridley, Microstructure of High-Tensile Strength Brasses Containing Silicon and Manganese, Mater. Trans., 1989, 20(7), p 1199–1206.

N.Y. Titarev, V.Y. Moroz and A.G. Melakh, Treatment Structure and Mechanical Properties of LMtsSK-type Brass After Strengthening Heat Treatment, Met. Sci. Heat Treat., 1986, 28(11), p 828–832.

N.B. Pugacheva, Structure and Properties of Alloys and Coatings with Ordered β-phase After Heat Treatment, Met. Sci. Heat Treat, 2007, 49(5–6), p 240–247.

A. Waheed and N. Ridley, Microstructure and Wear of Some High-Tensile Brasses, J. Mater. Sci., 1994, 29(6), p 1692–1699.

H. Li, J.C. Jie, S.C. Liu, Y.B. Zhang and T.J. Li, Crystal Growth and Morphology Evolution of D88 (Mn, Fe)5Si3 phase and its Influence on the Mechanical and Wear Properties of Brasses, Mater. Sci. Eng. A, 2017, 704(17), p 45–56.

L.F. Bie, X.H. Chen, P. Liu, T. Zhang and X.G. Xu, Morphology Evolution of Mn5Si3 Phase and Effect of Mn content on Wear Resistance of Special Brass, Met. Mater. Int., 2019, 26(3), p 431–443.

N.B. Pugacheva, A.A. Pankratov, N.Y. Frolova and I.V. Kotlyarov, Structural and phase transformations in α + β brasses, Russ. Metall, 2006, 2006(3), p 239–248.

R.K. Mysik, A.V. Sulitsin and S.V. Brusnitsyn, Influence of Intermetallics on Complex Alloyed Brass Hardness, Solid State Phenom, 2017, 265, p 789–792.

Z.W. Wang, S.H. Chen, Y.F. Li, L.J. Peng and H.F. Xie, Influence of Ce on Microstructures and Mechanical Properties of HMn64-8-5-1.5 Brass, Mater. Sci. Forum, 2016, 852, p 472–479.

H. Li, J.C. Jie, Q. Zhang and T.J. Li, Effect of Annealing Treatment on the Microstructures, Mechanical, and Wear Properties of a Manganese Brass Alloy, J. Mater. Res., 2016, 31(10), p 1491–1500.

J. Anantapong, V. Uthaisangsuk, S. Suranuntchai and A. Manonukul, Effect of Hot Working on Microstructure Evolution of as-cast Nickel Aluminum Bronze Alloy, Mate. Des., 2014, 60(8), p 233–243.

C. Mapelli and R. Venturini, Dependence of the Mechanical Properties of an α/β Brass on the Microstructural Features Induced by Hot Extrusion, Scripta Mater., 2006, 54(6), p 1169–1173.

L. Suárez, P. Rodriguez-Calvillo, J.M. Cabrera, A. Martínez-Romay and D. Majuelos-Mallorquín.A,(2015) Hot working Analysis of a CuZn40Pb2 Brass on the Monophasic (β) and Intercritical (α+β) Regions, Mater. Sci. Eng. A, 627: 42-50

M. Aghaie-Khafri and A. Mohebati-Jouibari, Thermomechanical Treatment of 70/30 Brass Containing Iron Impurity, J. Mater. Sci., 2006, 41(22), p 7585–7589.

Q. Wang, C.J. Ji, Y.G. Wang, J.B. Qiang and C. Dong, β-Ti Alloys with Low Young’s Moduli Interpreted by Cluster-Plus-Glue-Atom Model, Metall. Mater. Tran. A, 2013, 44, p 1872–1879.

C. Pang, B.B. Jiang, Y. Shi, Q. Wang and C. Dong, Cluster-Plus-Glue-Atom Model And Universal Composition Formulas [cluster](glue atom)x for BCC Solid Solution Alloys, J. Alloys Compd., 2015, 652, p 63–69.

Y. Ma, Q. Wang, B.B. Jiang, C.L. Li, J.M. Hao, X.N. Li, C. Dong and T.G. Nieh, Controlled Formation of Coherent Cuboidal Nanoprecipitates in Body-Centered Cubic High-Entropy Alloys based on Al2(Ni Co, Fe, Cr)14 Compositions, Acta. Mater., 2018, 147, p 213–225.

Q.X. Yu, X.N. Li, X N, K.R Wei, Z.M. Li, Y.H. Zheng, N.J. Li, X.T. Cheng, C.Y. Wang, Q. Wang and C. Dong,(2019) Cu–Ni–Sn–Si Alloys Designed by Cluster-Plus-Glue-Atom Model, Mater. Des 167: 107641

H.L. Hong, Q, Wang, C, Dong and P.K. Liaw,(2014) Understanding the Cu-Zn Brass Alloys using a Short-Range-Order Cluster Model: Significance of Specific Compositions of Industrial alloys, Sci. Rep., 4: 7065

Baker H, ASM Handbook volume 3-alloy phase diagrams, ASM International, US, 1992, p. 780

A. Takeuchi and A. Inoue, Calculations of Mixing Enthalpy and Mismatch Entropy for Ternary Amorphous Alloys, Mater. Tran. JIM, 2007, 41(11), p 1372–1378.

H. Mindivan, H. Cimenoglu and E.S. Kayali, Microstructures and Wear Properties of Brass Synchroniser Rings, Wear, 2003, 254(5), p 532–537.

S.M. Dasharath, C.C. Koch and S. Mula, Effect of Stacking Fault Energy on Mechanical Properties and Strengthening Mechanisms of Brasses Processed by Cryorolling, Mater. Charact., 2015, 110, p 14–24.

N.N. Krishna, R. Tejas, K. Sivaprasad and K. Venkateswarlu, Study on Cryorolled Al-Cu Alloy using X-ray Diffraction Line Profile Analysis and Evaluation of Strengthening Mechanisms, Mater. Des., 2013, 52, p 785–790.

V.S. Sarma, K. Sivaprasad and D. Sturm.M. Heilmaier,(2008) Microstructure and Mechanical Properties of Ultra Fine Grained Cu–Zn and Cu–Al Alloys Produced by Cryorolling and Annealing, Mater. Sci. Eng. A, 489(1-2): 253-258

D.V. Kudashov, H. Baum, U. Martin, M. Heilmaier and H. Oettel, Microstructure and Room Temperature Hardening of Ultra-Fine-Grained Oxide-Dispersion Strengthened Copper Prepared by Cryomilling, Mater. Sci. Eng. A, 2004, 387, p 768–771.

G. Qin, R.R. Chen, H.T. Zheng, H.Z. Fang, L. Wang, Y.Q. Su, J.J. Guo and H.Z. Fu, Strengthening FCC-CoCrFeMnNi High Entropy Alloys by Mo Addition, J. Mater. Sci. Technol., 2019, 35, p 578–583.

H. Zhuo, J.C. Tang and N. Ye, A Novel Approach for Strengthening Cu-Y2O3 Composites by In situ Reaction at Liquidus Temperature, Mater. Sci. Eng. A, 2013, 584(1), p 1–6.

E.I. Galindo-Nava, W.M. Rainforth and P.E.J. Rivera-Díaz-del-Castillo, Predicting Microstructure and Strength of Maraging Steels: Elemental Optimisation, Acta Mater., 2016, 117, p 270–285.

Acknowledgments

It was supported by the National Natural Science Foundation of China [91860108] and Natural Science Foundation of Liaoning Province of China (2019-KF-05-01).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gou, P., Niu, B., Wang, N. et al. Composition-Optimized Cu-Zn-(Mn, Fe, Si) Alloy and Its Microstructural Evolution with Thermomechanical Treatments. J. of Materi Eng and Perform 31, 590–601 (2022). https://doi.org/10.1007/s11665-021-06206-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06206-0