Abstract

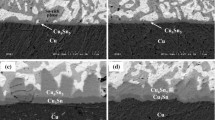

This paper investigated the melting point and surface oxide thickness of Sn58Bi clean solder (non-flux-coated solder with a clean surface). The surface morphology, spreadability, voidage, and interfacial reaction of Sn58Bi clean solder and flux-coated solder welded with three different surface finishes were studied during vacuum welding and atmospheric reflow welding. The surface finishes consisted of pure copper, matte tin, and gold plating. The results indicated that the optimal welding surface finish of Sn58Bi clean solder was gold plating, and the interfacial reaction was sufficient and the average voidage was 7.69%. The interfacial intermetallic compound (IMC) was approximately 0.6-1 um thick, uneven and discontinuous. As for flux-coated solder, the preferable surface finish was matte tin, which had good welding surface morphology and formed a continuous smooth IMC layer with a thickness of about 0.4-0.8 um; spreading ratio and average voidage were 101.64% and 4.03%, respectively. An unknown particle-shaped Au-Sn-Bi phase ɑ with Au:Sn:Bi (wt.%) ≈ 18.5:56.2:24.2 (Au15Sn68Bi17 (at.%)) was discovered in the welding interface of Sn58Bi solder and gold-plated substrate. In addition, another Au-Sn-Bi ternary compound β with Au:Sn:Bi (wt.%) ≈ 27.8:65.5:6.7 (Au19Sn76Bi5 (at.%)) was found in Au18.5Sn56.2Bi24.2 (wt.%) alloy which prepared by smelting. (Au15Sn68Bi17 (at.%) named ɑ and Au19Sn76Bi5 (at.%) named β in the present work).

Similar content being viewed by others

References

D. Ye, C. Du, M. Wu, and Z. Lai, Microstructure and mechanical properties of Sn–xBi solder alloy. J. Mater. Sci. Mater. Electron. 26, 3629 (2015).

M.H. Roh, J.P. Jung, and W. Kim, Microstructure, shear strength and nanoindentation property of electroplated Sn–Bi micro-bumps. Microelectron. Reliab. 54, 265 (2014).

Z. Lai, and D. Ye, Effect of cooling method and aging treatment on the microstructure and mechanical properties of Sn–10Bi solder alloy. J. Mater. Sci. Mater. Electron. 27, 1398 (2016).

H. He, Xu. Guangchen, and Fu. Guo, Electromigration-induced Bi-rich whisker growth in Cu/Sn–58Bi/Cu solder joints. J. Mater. Sci. 45, 334 (2010).

A.M. Delhaise, Z. Bagheri, S. Meschter, P. Snugovsky, and J. Kennedy, Tin whisker growth on electronic assemblies soldered with Bi-containing, Pb-free alloys. J. Electron. Mater. 50, 842 (2020).

Q. Li, N. Ma, Y. Lei, J. Lin, Fu. Hanguang, and Gu. Jian, Characterization of low-melting-point Sn-Bi-In lead-free solders. J. Electron. Mater. 45, 5800 (2016).

N. Jiang, L. Zhang, L.-L. Gao, X.-G. Song, and P. He, Recent advances on SnBi low-temperature solder for electronic interconnections. J. Mater. Sci. Mater. Electron. 32, 22731 (2021).

R. Sui, F. Li, W. Ci, and Q. Lin, Wetting of Cu and Cu-Sn IMCs by Sn-Bi alloys over wide composition at 350°C. J. Electron. Mater. 48, 4660 (2019).

J.W. Jang, P.G. Kim, and K.N. Tu, High-temperature lead-free SnSb solders: Wetting reactions on Cu foils and phased-in Cu–Cr thin films. J. Mater. Res. 14, 3895 (1999).

Z. Moser, W. Gasior, and J. Pstrus, Surface tension measurements of the Bi-Sn and Sn-Bi-Ag liquid alloys. J. Electron. Mater. 30, 1104 (2001).

E.P. Leng, D. Min, I. Ahmad, H.H. Jiun, and K. Hazlindal, Lead-free flux effect in lead-free solder joint improvement. IEEE/CPMT. (2006). https://doi.org/10.1109/IEMT.2006.4456509.

D. Xu, X. Li, C. Wang, and B. Xu, Study on wettability and corrosivity of a new no-clean flux for lead-free solder paste in electronic packaging technology. IEEE. (2011). https://doi.org/10.1109/MACE.2011.5987285.

H. Liu, F. Xue, and J. Zhou, Study of flux on wetting behavior of Sn-Zn lead-free solders. Adv. Mater. Res. 189–193, 3230 (2011).

J.K. Choi, H.B. Kang, J.W. Lee, S.B. Jung, and C.W. Yang, A study on interfacial reaction between electroless plated Ni-P/Au UBM and Sn-Bi eutectic solder using AEM. Mater. Sci. Forum. 449–452, 405 (2004).

H.-P. Shin, B.-W. Ahn, J.-H. Ahn, J.-G. Lee, K.-S. Kim, D.-H. Kim, and S.-B. Jung, Interfacial reaction and joint strength of the Sn-58Bi solder paste with ENIG surface finished substrate. J. Weld. Join. (2012). https://doi.org/10.5781/KWJS.2012.30.5.458.

C.S. Huang, J.H. Yeh, B.L. Young, and J.G. Duh, Phenomena of electroless Ni-P and intermetallic-compound stripping and dissolving in Sn-Bi and Sn-Pb solder joints with Au/EN/Cu metallization. J. Electron. Mater. 31, 1230 (2002).

D. Kim, and C.C. Lee, Fluxless bonding process in air using Sn–Bi–Au design. Mater. Sci. Eng. A. 372, 261 (2004).

M.G. Cho, K.W. Paik, H.M. Lee, S.W. Booh, and T.G. Kim, Interfacial reaction between 42Sn-58Bi solder and electroless Ni-P/immersion Au under bump metallurgy during aging. J. Electron. Mater. 35, 35 (2006).

Y. Liu, S. Li, W. Song, X. Wang, H. Zhang, and F. Sun, Interfacial reaction microstructure and mechanical properties of Sn58Bi solder joints on graphene-coated Cu substrate. Results Phys. 13, 102256 (2019).

Y. Goh, A. Haseeb, H.L. Liew, and M.F.M. Sabri, Deformation and fracture behaviour of electroplated Sn–Bi/Cu solder joints. J. Mater. Sci. 50, 4258 (2015).

F. Wang, Y. Huang, Z. Zhang, and C. Yan, Interfacial Reaction and Mechanical Properties of Sn-Bi Solder joints. Materials. 10, 920 (2017).

S.M. Lee, J.W. Yoon, and S.B. Jung, Interfacial reaction and mechanical properties between low melting temperature Sn–58Bi solder and various surface finishes during reflow reactions. J. Mater. Sci. 26, 1649 (2015).

J. Pang, L. Xu, X.Q. Shi, W. Zhou, and S.L. Ngoh, Intermetallic growth studies on Sn-Ag-Cu lead-free solder joints. J. Electron. Mater. 33, 1219 (2004).

H.T. Lee, and M.H. Chen, Influence of intermetallic compounds on the adhesive strength of solder joints. Mater. Sci. Eng. A. 333, 24 (2002).

Y.H. Baek, B.M. Chung, Y.S. Choi, J. Choi, and J.Y. Huh, Effects of Ni3Sn4 and (Cu, Ni)6Sn5 intermetallic layers on cross-interaction between Pd and Ni in solder joints. J. Alloys Compd. 579, 75 (2013).

P.K. Bernasko, S. Mallik, and G. Takyi, Effect of intermetallic compound layer thickness on the shear strength of 1206 chip resistor solder joint. Solder. Surf. Mt. Technol. 27, 52 (2015).

F. Gao, C. Wang, and X. Liu, Thermodynamic assessment of phase equilibria in the Sn-Au-Bi system with key experimental verification. J. Electron. Mater. 25, 576 (2010).

H.M. Hsiao, Y.W. Chang, C.M. Chen, C.M. Chen, Y.P. Wu, and Y.W. Yen, Phase equilibria in the Au–Bi–Sn ternary system at temperatures of 80, 125, and 150°C. Int. J. Mater. Res. 107, 1 (2016).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author declares that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material

Rights and permissions

About this article

Cite this article

Zhang, Y., Lin, Q. & Li, Z. Effect of Surface Finishes on the Welding of Sn58Bi Solder. J. Electron. Mater. 51, 1106–1115 (2022). https://doi.org/10.1007/s11664-021-09339-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-09339-z