Abstract

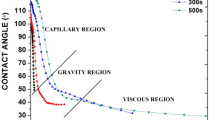

This paper explores the effects of Germanium (Ge) addition on the wetting behavior, copper dissolution, IMC formation, microstructure and mechanical behavior of SnCu alloy. Static copper dissolution was conducted as a function of contact time and in the temperature range of 260–300 °C. The results show that the Ge doped alloy has the lowest copper dissolution rate compared to SnCu, SAC305, and very much comparable with SnPb solder thus making it suitable alloy for the wave soldering process. Two solderability standards measurement (JIS vs. IPC) have been executed on different surface finishes such as OSP, ENIG, ImAg commonly used in industrial soldering process. The results showed that addition of Ge significantly improves the wetting/spread performance for all the surface finishes (ENIG, OSP and ImAg). Contact angles range from 17°–30°, the lowest contact angles being observed on ENIG surface. Microstructural analysis showed Ge addition refine the grain structure of SnCu–0.01Ge alloy. A thin IMC layer was observed, and IMC growth was not significant after multiple reflows as compared to Sn–Cu alloy. Similarly, Ge addition increases the hardness value due to uniform microstructure of SnCu–Ge alloy. The tensile testing results also showed an increase in tensile strength and tolerable ductility.

Similar content being viewed by others

References

M. Abtew, G. Selvaduray, Lead free solders in microelectronics. Mater. Sci. Eng. R 27, 95–141 (2000)

J.W. Evans, A Guide to Lead-Free Solders: Physical Metallurgy and Reliability, Springer, New York, 2007

H.Z. Huang, X.Q. Wei, D.Q. Tan, L. Zhou, Effects of phosphorus addition on the properties of Sn–9Zn lead free solder alloy. Int. J. Miner. Metall. Mater. 6, 563–567 (2013)

A. Xian, G.L. Gong, Oxidation behavior of molten tin doped with phosphorus. J. Electron. Mater. 12, 1669–1678 (2007)

K.M. Watling, A. Chandler-Temple, K. Nogita, XPS analysis of oxide films on lead free solders with trace additions of germanium and gallium. Mater. Sci. Forum 857, 63–67 (2016)

X. Yan, K. Xu, J. Wang, X. Wei, W. Wang, Effect of P and Ge doping on microstructure of Sn-0.3 Ag-0.7 Cu/Ni–P solder joints, Soldering Surf. Mount Technol. 28, 215–221 (2016)

E.P. Leng, W.T. Ling, N. Amin, I. Ahmad, T.Y. Han, C.W. Chiao, A.S.M.A. Haseeb, BGA lead free C5 solder system improvement by Germanium addition to Sn3.5Ag and Sn-3.8 Ag-0.7 Cu solder alloy. in Electronics Packaging Technology Conference, pp. 82–91, 2009

M.G. Cho, S.K. Seo, H.M. Lee, Undercooling, microstructures and hardness of Sn-rich Pb-free solders on Cu-xZn alloy under bump metallurgies. Mater. Trans. 50, 2291–2296 (2009)

A. Sharif, Y.C. Chan, Dissolution kinetics of BGA Sn–Pb and Sn–Ag solders with Cu substrates during reflow. Mater. Sci. Eng. B 106, 126–131 (2004)

F. Byle, D. Jean, D. Lee, A study of copper dissolution in Pb-Free solder fountain systems, in Proceedings of SMTA International, 2006

D. Maio, C.P. Hunt, On the factors affecting the dissolution of copper in molten lead free solders and development of a method to assess the soldering parameters. Soldering Surf. Mount Technol. 21, 24–31 (2009)

J.F. Li, S.H. Mannan, M.P. Clode, D.C. Whalley, D.A. Hutt, Interfacial reactions between molten Sn–Bi–X solders and Cu substrates for liquid solder interconnects. Acta Mater. 54, 2907–2922 (2006)

G. Humpston, D.M. Jacobson, Solder spread: a criterion for evaluation of soldering. Gold Bull. 3, 83–96 (1990)

P.T. Vianco, An overview of surface finishes and their role in printed circuit board solderability and solder joint performance. Circ. World 25, 6–24 (1999)

M.F. Arenas, V.L. Acoff, Contact angle measurements of Sn–Ag and Sn–Cu lead free solders on copper substrates. J. Electron. Mater. 12, 1452–1458 (2004)

S.H. Wang, T.S. Chin, C.F. Yang, S.W. Chen, C.T. Chuang, Pb-free solder alloy based on Sn–Zn–Bi with the addition of germanium. J. Alloys Compd. 497, 428–431 (2010)

R.J.K. Wassink, Soldering in Electronics: A Comprehensive Treatise on Soldering Technology for Surface Mounting and Through Hole Techniques, Electrochemical Publications, Scotland, 1994

R.W. Hertzberg, Deformation and Fracture Mechanics of Engineering Materials, 4th edn. Wiley, New York, 1996

F. Lang, H. Tanaka, O. Munegata, T. Taguchi, T. Narita, The effect of strain rate and temperature on the tensile properties of Sn–3.5 Ag solder. Mater. Charact. 54(3), 223–229 (2005)

Acknowledgements

This research was supported by Kester R & D, material science division. The authors thankful to ITW Tech Center and Buehler for sample preparation and analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hasnine, M., Tolla, B. & Karasawa, M. Effect of Ge addition on wettability, copper dissolution, microstructural and mechanical behavior of SnCu–Ge solder alloy. J Mater Sci: Mater Electron 28, 16106–16119 (2017). https://doi.org/10.1007/s10854-017-7511-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7511-4