Abstract

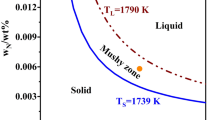

The precipitation of TiN inclusion during the solidification of SWRH92A high carbon tire cord steel has been thermodynamically calculated. The influence of solute micro-segregations calculated by Ohnaka and Clyne–Kurz models, respectively, on the thermodynamic parameters is considered. The TiN precipitation module is coupled with the Ti and N micro-segregations when the condition of TiN precipitation is satisfied. Furthermore, the TiN growth is predicted based on the thermodynamic calculation results. The results first show that the solute elements of molten steel segregate to different extents during solidification. The carbon concentration increases most significantly by about 1.8 wt pct due to its highest original content. By coupling TiN precipitation module with solute micro-segregation module, the segregated ratios of Ti and N decrease after the TiN inclusion starts precipitating. With cooling rate increasing from 0.17 to 1.67 K/s, TiN precipitation starts earlier, but the TiN particle size decreases from about 10 to about 3 μm. The TiN inclusion sizes calculated in the Ohnaka and Clyne–Kurz model cases are close and well validated by the metallographic images of TiN inclusions and the statistical data of TiN particle size distribution in high carbon tire cord steels. This agreement encourages the proposed calculation method and provides guidance for the future thermodynamic studies of nonmetallic inclusions of steel.

Similar content being viewed by others

References

S. K. Michelic, D. Loder, T. Reip, A. ArdehaliBarani and C. Bernhard: Mater. Charact., 2015, vol. 100, pp. 61-67.

V. Descotes, S. Migot, F. Robaut, J.P. Bellot, V. Perrin-Guérin, S. Witzke and A. Jardy: Metall. Trans. A, 2015, vol. 46, pp. 2793-2795.

J. Y. Li and W. Y. Zhang: ISIJ Int., 1989, vol. 29, pp. 158-164.

J. Y. Yang, C. Ling, J. Z. Tang, C. Ni and L. C. Xiao: Heat Treat. Met., 2012, vol. 37, pp. 32-37.

J. Petit and C. Sarrazin-Baudoux: Key Eng. Mater., 2015, vol. 627, pp. 153-156.

W. Yan, Y. Y. Shan and K. Yang: Metall. Trans A, 2007, vol. 38, pp. 1211-1222.

J. L. Lei, Z. L. Xue and Y. D. Jiang: Metal. Int., 2012, vol. 17, pp. 10-15.

J. L. Lei, Z. L. Xue, Y. D. Jiang, J. Zhang, R. Xiong and F. Zou: J. Mater. Metall., 2014, vol. 13, pp. 125-127.

H. Y. Liu, H. L. Wang, L. Li, J. Q. Zheng, Y. H. Li and X. Y. Zeng: Ironmak. & Steelmak., 2011, vol. 38, pp. 53-58.

J. Fu, J. Zhu, L. Di, F. Tong and Y. Wang: Acta Metall. Sin., 2000, vol. 36, pp. 801-804.

Jiang YD, Xue ZL, Zhang J (2014) J. Iron Steel Res. Int. 21(1):91-94.

J. L. Lei, D. N. Zhao, Y. J. Fu and X. F. Xu: Arch. Foundry Eng., 2019, vol. 19, pp. 33-37.

Z. L. Xue, W. T. Jin, J. L. Lei and Y. D. Jiang: Steelmak., 2016, vol. 32, pp. 23-32.

X. F. Cai, Y. P. Bao, M. Wang, L. Lin, N. C. Dai and C. Gu: Metall. Res. Tech., 2015, vol. 112, pp. 407-418.

L. Wang, Z. L. Xue, H. Y. Zhu and J.L. Lei: Results Phys., 2019, vol. 14, pp. 102428-102434.

J. Chen: Manual of chart and data in common use of steel making, 2nd ed., The Metallurgical Industry Press, Beijing, 2010, p. 510.

Q. Tian, G. C. Wang, Y. Zhao, J. Li and Q. Wang: Metall. Trans. B, 2018, vol. 49, pp. 1149–1164.

Z. Ma and D. Janke: ISIJ Int., 1998, vol. 38, pp. 46–52.

X. F. Wan, J. S. Meng, D. G. Li, D. Y. Guo, J. X. Jia, X. W. Liao and D. Cao: Proc. Int. Symp. on Clean Steel Prod. Tech., The Chinese Society for Metals, Anshan, 2018, pp. 171–75.

D. L. You, S. K. Michelic, P. Presoly, J. H. Liu and C. Bernhard: Metals, 2017, vol. 7, pp. 460.

E. Scheil: Metallkunde, 1942, vol. 34, pp. 70–72.

H. D. Brody and M. C. Flemings: Trans. Metall. Soc. AIME, 1966, vol. 236, pp. 615–624.

T. W. Clyne and W. Kurz: Metall. Trans. A, 1981, vol. 12, pp. 965–971.

I. Ohnaka: Trans. Iron Steel Inst. Japan, 1986, vol. 26, pp. 1045–1051.

L. Wang, Z. L. Xue, Y. L. Chen and X. G. Bi: Processes, 2020, vol. 8, pp. 10-22.

J. L. Lei, D. N. Zhao, H. Y. Zhu and Y. D. Jiang: Steelmak., 2018, vol. 34, pp. 66-71.

E. B. Yue, S.T. Qiu and Y. Gan: J. Iron Steel Res., 2007, vol. 19, pp. 35-38.

S. Luo, M. Y. Zhu, C. Ji and Z. Z. Cai: Iron Steel, 2010, vol. 45, pp. 31-36.

L. Yang, G. G. Cheng, S. J. Li, M. Zhao and G. P. Feng: ISIJ Int., 2015, vol. 55, pp. 1693-1698.

X. Zhang, G. J. Ma and M. K. Meng: Philos. Mag., 2019, vol. 99, pp. 1041-1056.

Y. M. Won and B. G. Thomas: Metall. Trans. A, 2001, vol. 32, pp. 1755–1167.

Z. Z. Liu, J. Wei and K. K. Cai: ISIJ Int., 2002, vol. 42, pp. 958-963.

D. L. Hu, H. Liu, J. B. Xie, J. Cheng, J. Li and J. X. Fu: J. Iron Steel Res. Int., 2018, vol. 25, pp. 803-812.

W. J. Ma, Y. P. Bao, L. H. Zhao and M. Wang: Metall. Mater., 2014, vol. 21, pp. 234-239.

Y. N. Wang, J. Yang, X. L. Xin, R. Z. Wang and L. Y. Xu: Metall. Trans. B, 2016, vol. 47, pp. 1378–1389.

J. H. Shin and J. H. Park: Metall. Trans. B, 2020, vol. 51B, pp. 1211–1224.

D. L. You, S. K. Michelic, C. Bernhard, D. Loder and G. Wieser: ISIJ Int., 2016, vol. 56, pp. 1770-1778.

C. F. Yu and Z. L. Xue: J. Wuhan Uni. Sci. Tech., 2015, vol. 38, pp. 241-244.

Y. H. Li, J. Q. Zheng, G. Q. Lin and H. Y. Liu: Proc. Symp. on Adv. Spec. Steel Prod. Tech., The Chinese Society for Metals, Beijing, 2011, pp. 368–71.

D. Y. Guo, Y. H. Ren, B. X. Wang, H. Gao and B. Zhang: Proc. Symp. on Domest. Steelmaking–Continuous Casting Prod. Tech., The Chinese Society for Metals, Tangshan, 2014, pp. 327–31.

H. Y. Liu, J. Q. Zheng, Y. H. Li, G. Q. Lin, Z. L. Xue and H. L. Wang: J. Uni. Sci. Tech. Beijing, 2010, vol. 32, pp. 866-871.

Z. L. Xue, C. F. Yu, L. W. Qiu, W. T. Chen and J. Zhang: J. Chongqing Uni., 2015, vol. 38, pp. 93-98.

N. Li, L. Wang, Z. L. Xue, C. Z. Li, A. Huang and F. F. Wang: Results Phys., 2020, vol. 16, pp. 102929-102937.

Acknowledgments

The authors gratefully acknowledge the financial support for this work from the National Natural Science Foundations of China (Grant Nos. 51874214, 51804230), China Postdoctoral Science Foundation (Grant No. 2020M672425), and Hubei Provincial Natural Science Foundation (Grant No. 2020CFB133).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 17, 2020, accepted April 1, 2021.

Rights and permissions

About this article

Cite this article

Wang, P., Li, C., Wang, L. et al. Thermodynamic Analysis of TiN Precipitation in SWRH92A High Carbon Tire Cord Steel Under the Influence of Solute Micro-segregations During Solidification. Metall Mater Trans B 52, 2056–2071 (2021). https://doi.org/10.1007/s11663-021-02166-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02166-x