Abstract

An experimental investigation of the reduction of magnetite concentrate particles was conducted in a laboratory-scale flash reactor representing a novel flash ironmaking process. In this reactor, methane was partially oxidized by oxygen to form a reducing H2 + CO gas mixtures. The test variables in this work included the particle residence time, the extent of excess reducing gases, particle feeding mode, and flame configuration. The experimental results obtained from this reactor proved that the concentrate particles can be reduced directly in a flash reactor utilizing natural gas. More than 80 pct reduction was achieved in this reactor despite its low operating temperature (1170 °C). In addition, a three-dimensional computational fluid dynamics model was developed to describe the reduction of concentrate particles in this reactor. The model was used to simulate the fluid flow, heat transfer, and chemical reactions involved. The gas phase was simulated in the Eulerian frame of reference, while the particles were tracked in the Lagrangian framework. The partial combustion of methane by oxygen was also simulated in this study. The temperature profile obtained from the simulations satisfactorily agreed with the experimental measurements, while the calculated reduction degrees consistently over predicted the experimental values. This was attributed to the soot formation as a consequence of methane cracking due to large metal surface of the reactor. The soot formation led to a high-water vapor generation in the partial combustion, which lowered the excess of hydrogen.

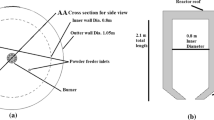

Adapted from Ref. [30]

Similar content being viewed by others

Abbreviations

- d p :

-

Geometric mean diameter of the screened particle (m)

- K j :

-

Equilibrium constant for the reduction of FeO by gas j

- L :

-

Effective length where temperature remained within 1175 ± 25 K (m)

- p :

-

Pressure (Pa)

- u g :

-

Gas phase velocity (m s−1)

- u t :

-

Terminal velocity of the particle (m s−1)

- X :

-

Reduction degree

- μ :

-

Gas phase viscosity (N m s−2)

- ρ g :

-

Gas phase density (kg m−3)

- ρ p :

-

Particle density (kg m−3)

- τ :

-

Particle residence time (s)

References

Steel’s Contribution to a Low Carbon Future and Climate Resilient Societies (2017). https://www.steel.org.au/resources/elibrary/resource-items/steel-s-contribution-to-a-low-carbon-future-and-cl. Accessed October 30, 2018.

Themelis NJ, Zhao B (1995) In: Davies TW (ed) Flash Reaction Processes. Kluwer Academic Publishers, Dordrecht, pp 273-93

Johnson T, Davison J (1964) J Iron Steel Inst 202:406-19

Perez-Tello M, Sohn HY, St Marie K, Jokilaakso A (2001) Metall Mater Trans B 32B:847-68

M. Perez-Tello, H. Y. Sohn and P. J. Smith: Metall. Mater. Trans. B., 2001, vol. 32 (5), pp. 869-86.

A. Jokiaakso, T. Ahokainen, O. Teppo, Y. Yang and K. Lilius: Miner. Process. Extr. Metall. Rev., 1995, vol. 15 (1-4), pp. 217-34.

H. Y. Sohn: Steel Times Int., 2007, vol. 31, pp. 68-72.

H. Y. Sohn, M. E. Choi, Y. Zhang, and J. E. Ramos: AIST Trans., 2009, vol. 6 (8), pp. 158-65.

M. E. Choi and H. Y. Sohn: Ironmaking Steelmaking, 2010, vol. 37 (2), pp. 81-88.

H. K. Pinegar, M. S. Moats, and H. Y. Sohn: Steel Res. Int., 2011, vol. 82 (8), pp. 951-63.

H. K. Pinegar, M. S. Moats, and H. Y. Sohn: Ironmaking Steelmaking, 2012, vol. 39 (6), pp. 398-408.

H. K. Pinegar, M. S. Moats, and H. Y. Sohn: Ironmaking Steelmaking, 2013, vol. 40 (1), pp. 44-49.

H. Y. Sohn and M. Olivas-Martinez: JOM, 2014, vol. 66 (9), pp. 1557-64.

H. Y. Sohn and Y. Mohassab, J. Sust. Metall., 2(3), 216–227 (2016).

Elzohiery M, Mohassab Y, Sohn HY (2017) Steel Res Int 88:1600133

F. Chen, Y. Mohassab, T Jiang and H. Y. Sohn: Metall. Mater. Trans. B, 2015, vol. 46 (3), pp. 1133-45.

D. Fan, Y. Mohassab, M. Elzohiery and H. Y. Sohn: Metall. Mater. Trans. B, 2016, vol. 47 (3), pp. 1669-80.

F. Chen, Y. Mohassab, S. Zhang and H. Y. Sohn: Metall. Mater. Trans. B, 2015, vol. 46 (4), pp. 1716-28.

D. Fan, H. Y. Sohn, Y. Mohassab and M. Elzohiery: Metall. Mater. Trans. B, 2016, vol. 47 (6), pp 3489-500.

D. Fan, H. Y. Sohn and M. Elzohiery: Metall. Mater. Trans. B, 2017, vol. 48 (5), pp. 2677-84.

D. Fan, M. Elzohiery, Y. Mohassab, and H.Y. Sohn: in 8th International Symposium on High-Temperature Metallurgical Processing, J.Y. Hwang, et al., eds., Springer, 2017, pp. 61–70.

H.Y. Sohn, Y. Mohassab, M. Elzohiery, D. Fan, and A. Abdelghany: in Applications of Process Engineering Principles in Materials Processing, Energy and Environmental Technologies, S. Wang, et al., eds., Springer, 2017, pp. 15–23. https://doi.org/10.1007/978-3-319-51091-0_2.

D. Fan: PhD Dissertation, University of Utah, Salt Lake City, Utah, 2019.

HSC 5.11, Chemistry for Windows, Outokumpu Research, Oy, Pori, 2002.

J. H. Ferziger and M. Peric, Computational Methods for Fluid Dynamics, Springer-Verlag, Berlin, 2002.

W. P. Jones and R. P. Lindstedt, Combust. Flame, 1988, 73(3), pp.233-249.

I. R. Gran and B. F. Magnussen: Combust. Sci. Technol., 1996, vol. 119 (1-6), pp. 191-217.

Fluent Theory Guide, ANSYS, Inc., Canonsburg, USA.

R.J. Kee, F.M. Rupley, C. Wang, and O. Adigun: CHEMKIN Collection, Release 3.6, Reaction Design, Inc., San Diego, CA, 2000.

M. Elzohiery: PhD Dissertation, University of Utah, Salt Lake City, Utah, 2018.

Acknowledgments

The technical support and resources provided by the Center for High Performance Computing at the University of Utah are gratefully acknowledged. The authors acknowledge the financial support from the U.S. Department of Energy under Award Number DE-EE0005751 with cost share by the American Iron and Steel Institute (AISI) and the University of Utah.

Disclaimer

This report was prepared as an account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 27, 2019.

Rights and permissions

About this article

Cite this article

Elzohiery, M., Fan, D., Mohassab, Y. et al. Experimental Investigation and Computational Fluid Dynamics Simulation of the Magnetite Concentrate Reduction Using Methane-Oxygen Flame in a Laboratory Flash Reactor. Metall Mater Trans B 51, 1003–1015 (2020). https://doi.org/10.1007/s11663-020-01809-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01809-9