Abstract

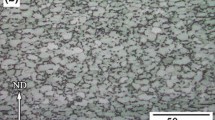

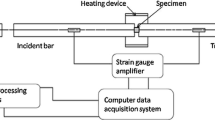

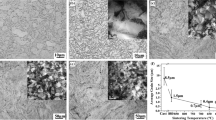

Ultrafine-grained (UFG) Ti-6Al-4V alloy with average grain sizes of 305, 430, and 669 nm was fabricated by high-energy ball-milling and spark plasma sintering. The mechanical behaviors of consolidated titanium alloy with different grain sizes were studied under uniaxial compression at the quasi-static strain rate of 1 × 10−3 s−1 and high strain rates ranging from 0.5 × 103 to 2.9 × 103 s−1. Shear bands can be observed in specimens tested under quasi-static and dynamic condition. It is discovered that when the grain size decreases, the flow stress increases and shear band instability takes place at lower strains. The flow stresses of UFG titanium alloy with different grain sizes demonstrate similar dependence on the strain rate when the strain rate ranges from 1 × 10−3 to 0.5 × 103 s−1. However, the strain rate sensitivity m dramatically increases at higher strain rates and is reduced with the decrease of grain size. It is considered that the propensity for adiabatic shear banding \( \chi_{\text{ASB}} \) during dynamic compression is increased with the reduction of grain size because of the improved yield strength as well as the diminished strain rate sensitivity.

Similar content being viewed by others

References

1. M.A. Meyers, A. Mishra, and D.J. Benson: Prog. Mater. Sci., 2006, vol. 51, pp. 427-556.

2. K.S. Kumar, H.V. Swygenhoven, and S. Suresh: Acta. Mater., 2003, vol. 51, 5743-5774.

3. Q. Wei, L. Kecskes, T. Jiao, K.T. Hartwig, K.T. Ramesh, and E. Ma: Acta Mater., 2004, vol. 52, pp. 1859-1869.

4. P. Q. La, J. Q. Ma, Y. T. Zhu, J. Yang, W. M. Liu, Q. J. Xue, and R. Z. Valiev: Acta Materialia., 2005, vol. 53, pp. 5167-5173.

5. W. J. Kim, C. Y. Hyun, and H. K. Kim: Scripta Materialia., 2006, vol. 54, pp. 1745-1750.

6. J. K. Fan, H. C. Kou, Y. D. Zhang, L. Germain, K. Hua, L. Y. Tang, C. Esling, and J. S. Li: J. Alloys Compd., 2019, vol. 770, pp. 183-193.

7. J. L. Sun, P. W. Trimby, X. Si, X. Z. Liao, N. R. Tao, and J. T. Wang: Scripta Materialia., 2013, vol. 68, pp. 475-478.

8. Y. Yang, X.M. Li, X.L. Tong, Q.M. Zhang, and C.Y. Xu: Mater. Sci. Eng. A., 2011, vol. 528, pp. 3130-3133.

9. B.F. Wang, and Y. Yang: Mater. Sci. Eng. A., 2008, vol. 473, pp. 306-311.

10. J.L. Sun, P.W. Trimby, F.K. Yan, X.Z. Liao, N.R. Tao, and J.T. Wang: Acta. Mater., 2014, vol. 79, pp. 47-58.

11. R.L. Woodward: Metall. Trans. A., 1979, vol. 10A, pp. 569-573.

12. Y. Me-bar, and D. Shechtman: Mater. Sci. Eng., 1983, vol. 58, pp. 181-188.

13. H.A. Grebe, H.R. Pak, and M.A. Meyers: Metall. Trans. A., 1985, vol. 16A, pp. 761-775.

14. M.A. Meyers, and H.R. Pak: Acta. Metall., 1986, vol. 34, pp. 2493-2499.

15. D. Jia, Y.M. Wang, K.T. Ramesh, E. Ma, Y.T. Zhu, and R.Z. Valiev: Appl. Phys. Lett., 2001, vol. 79, pp. 611.

16. F. Wang, B. Li, T.T. Gao, P. Huang, K.W. Xu, and T.J. Lu, Surf. Coat. Tech., 2013, vol. 228, pp. S254-S256.

17. S.X. Zhang, Y.C. Wang, A.P. Zhilyaev, E. Korznikova, S. Li, G.I. Raab, and T.G. Langdon, Mater. Sci. Eng. A., 2015, vol. 645, pp. 311-317.

18. Z. Li, B.F. Wang, S. Zhao, R.Z. Valiev, K.S. Vecchio, and M.A. Meyers, Acta Mater., 2017, vol. 125, pp. 210-218.

19. I.P. Semenova, G.I. Raab, L.R. Saitova, and R.Z. Valiev: Mater. Sci. Eng. A., 2004, vol. 387-389, pp. 805-808.

20. T.F. Zhou, J.J. Wu, J.T. Che, Y. Wang, X.B. Wang: Int. J Impact Eng., 2017, vol. 109, pp. 167-177.

21. Q. Xue, M.A. Meyers, and V.F. Nesterenko: Acta Mater., 2002, vol. 50, pp. 575-596.

22. J. Zhang, and Y. Wang: Mater. Lett., 2014, vol. 124, pp. 113-116.

23. Y. Wang, D.L. Lin, Y.X. Zhou, Y.M. Xia, and C.C. Law: Mater. Lett., 1999, vol. 40, pp. 140-145.

24. D. Jia, K.T. Ramesh, E. Ma, L. Lu, and K. Lu: Scr. Mater., 2001, vol. 45, pp. 613-620.

25. D. Jia, K.T. Ramesh, and E. Ma: Acta. Mater., 2003, vol. 51, pp. 3495-3509.

26. R.J. Asaro, and S. Suresh: Acta. Mater., 2005, vol. 53, pp. 3369-3382.

27. H. Conrad In: V.F. Zackey (Ed.), High strength materials, Wiley, New York 1965.

28. S.C. Liao, and J. Duffy: J. Mech. Phys. Solids., 1998, vol. 46, pp. 2201-2231.

29. M.A. Meyers, V.F. Nesterenko, J.C. LaSalvia, and Q. Xue: Mater. Sci. Eng. A., 2001, vol. 317, pp. 204-225

30. B.F. Wang, J. Li, J.Y. Sun, X.Y. Wang, and Z.L. Liu, Mater. Sci. Eng. A., 2014, vol. 612, pp. 227-235.

31. G.A. Li, L. Zhen, C. Lin, R.S. Gao, X. Tan, and C.Y. Xu: Mater. Sci. Eng. A., 2005, vol. 395, pp. 98-101.

32. N. Ranc, L. Taravella, V. Pina, and P. Herve, Mech. Mater., 2008, vol. 40, pp. 255-270.

33. T.W. Wright, The Physics and Mathematics of Adiabatic Shear Bands, Cambridge Press, Cambridge 2002.

34. M.A. Meyers, G. Subhash, B.K. Kad, and L. Prasad: Mech. Mater., 1994, vol. 17, pp. 175-193

35. X.Q. Liu, C.W. Tan, J. Zhang, F.C. Wang, and H.N. Cai: Int. J. Impact. Eng. 2009, vol. 36, pp. 1143-1149.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 51104066), Guangdong Provincial Foundation of Natural Science (Grant No. 2016A030313483), Guangdong Provincial Project for Science and Technology (Grant Nos. 2015A020214008 and 2015A010105011), and Science and Technology Research Project of Guangzhou (Grant No. 201505040925029)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 23, 2019.

Rights and permissions

About this article

Cite this article

Long, Y., Zhang, W., Peng, L. et al. Mechanical Behaviors of Ultrafine-Grained Ti-6Al-4V Alloy During Compression at Various Strain Rates. Metall Mater Trans A 51, 4765–4776 (2020). https://doi.org/10.1007/s11661-020-05895-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05895-x