Abstract

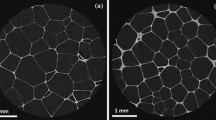

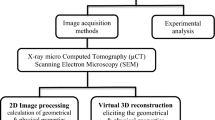

Aluminum foam is a lightweight material owing to the existence of a large number of internal pores. The compressive properties and deformation behavior of aluminum foam are considered to be directly affected by the shape and distribution of these pores. In this study, we performed image-based finite element (FE) analyses of aluminum foam using X-ray computed tomography (CT) images and investigated the possibility of predicting its deformation behavior by comparing the results of FE analyses with those of actual compressive tests. We found that it was possible to create an analytic model reflecting the three-dimensional (3D) pore structure using image-based modeling based on X-ray CT images. The stress distribution obtained from image-based FE analysis correctly indicates the layer where deformation first occurs as observed in actual compressive tests. Also, by calculating the mean stress of each plane perpendicular to the direction of compression based on the stress distribution obtained from image-based FE analysis, it was found that deformation begins in the layer containing the plane with maximum stress. It was thus possible to estimate the layer where deformation begins during the compression of aluminum foam.

Similar content being viewed by others

References

M.F. Ashby: Metall. Trans. A, 1983, vol. 14, pp. 1755–69.

A.G. Evans, J.W. Hutchinson, and M.F. Ashby: Prog. Mater. Sci., 1998, vol. 43, pp. 171–221.

L.J. Gibson: Ann. Rev. Mater. Sci., 2000, vol. 30, pp. 191–227.

A.G. Evans, J.W. Hutchinson, N.A. Fleck, M.F. Ashby, and H.N.G. Wadley: Prog. Mater. Sci., 2001, vol. 46, pp. 309–27.

J. Banhart: Prog. Mater. Sci., 2001, vol. 46, pp. 559–632.

H. Nakajima: Prog. Mater Sci., 2007, vol. 52, pp. 1091–1173.

A.F. Bastawros and A.G. Evans: Adv. Eng. Mater., 2000, vol. 2, pp. 210–14.

A.F. Bastawros, H. Bart-Smith, and A.G. Evans: J. Mech. Phys. Solids, 2000, vol. 48, pp. 301–22.

A.E. Markaki and T.W. Clyne: Acta Mater., 2001, vol. 49, pp. 1677–86.

D.J. Werther, A.J. Howard, J.P. Ingraham, and K.A. Issen: Scripta Mater., 2006, vol. 54, pp. 783–87.

M. Hakamada, T. Kuromura, Y. Chino, Y. Yamada, Y.Q. Chen, H. Kusuda, and M. Mabuchi: Mater. Sci. Eng. A, 2007, vol. 459, pp. 286–93.

N. Takano, M. Zako, F. Kubo and K. Kimura: Int. J. Solids Struct., 2003, vol. 40, pp. 1225–42.

S.J. Hollister and N. Kikuchi: Biotechnol. Bioeng., 1994, vol. 43, pp. 586–96.

Y. Shiino, O. Kuwazuru, and N. Yoshikawa: J. Theor. Biol., 2009, vol. 259, pp. 132–41.

Y. Hangai, O. Kuwazuru, T. Yano, T. Utsunomiya, Y. Murata, S. Kitahara, S. Bidhar, and N. Yoshikawa: Mater. Trans., 2010, vol. 51, pp. 1574–80.

N. Vanderesse, E. Maire, A. Chabod, and J.Y. Buffiere: Int. J. Fatigue, 2011, vol. 33, pp. 1514–25.

E. Maire, A. Fazekas, L. Salvo, R. Dendievel, S. Youssef, P. Cloetens and J.M. Letang: Compos. Sci. Technol., 2003, vol. 63, pp. 2431–43.

T. Kujime, M. Tane, S.K. Hyun, and H. Nakajima: Mater. Sci. Eng. A, 2007, vol. 460, pp. 220–26.

I. Jeon, T. Asahina, K.-J. Kang, S. Im, and T.J. Lu: Mech. Mater., 2010, vol. 42, pp. 227–36.

N. Michailidis, F. Stergioudi, H. Omar, and D. Tsipas: Comput. Mater. Sci., 2010, vol. 48, pp. 282–86.

H. Toda, M. Takata, T. Ohgaki, M. Kobayashi, T. Kobayashi, K. Uesugi, K. Makii, and Y. Aruga: Adv. Eng. Mater., 2006, vol. 8, pp. 459–67.

T. Miyoshi, M. Itoh, S. Akiyama, and A. Kitahara: Adv. Eng. Mater., 2000, vol. 2, pp. 179–83.

JIS-H-7902: Method for Compressive Test of Porous Metals, Japanese Standards Association, 2008.

Y. Hangai, S. Maruhashi, S. Kitahara, O. Kuwazuru, and N. Yoshikawa: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 2789–93.

The-Japan-Institute-of-Light-Metals: Structures and Properties of Aluminum, The Japan Institute of Light Metals, 1991, pp. 413–18.

A. Pollien, Y. Conde, L. Pambaguian, and A. Mortensen: Mater. Sci. Eng. A, 2005, vol. 404, pp. 9–18.

A.H. Brothers and D.C. Dunand: Mater. Sci. Eng. A, 2008, vol. 489, pp. 439–43.

K. Shinagawa: in Porous Metals and Metallic Foams, L.P. Lefebvre, J. Banhart, and D. Dunand, eds., Destech Pubns Inc, 2008, pp. 95–98.

Y. Hangai, Y. Oba, S. Koyama, and T. Utsunomiya: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 3585–89.

Y. Hangai, K. Takahashi, T. Utsunomiya, S. Kitahara, O. Kuwazuru, and N. Yoshikawa: Mater. Sci. Eng. A, 2012, vol. 534, pp. 716–19.

Acknowledgments

This study was partly financially supported by the Industrial Technology Research Grant Program in 2009 from the New Energy and Industrial Technology Development Organization (NEDO) of Japan and JKA promotion funds from AUTORACE. The authors thank Professor K. Saito, Gunma University, for his helpful advice on conducting the experiments, and T. Miyoshi, Shinko Wire Company, Ltd., for providing ALPORAS.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 2, 2012.

Rights and permissions

About this article

Cite this article

Hangai, Y., Yamaguchi, R., Takahashi, S. et al. Deformation Behavior Estimation of Aluminum Foam by X-ray CT Image-based Finite Element Analysis. Metall Mater Trans A 44, 1880–1886 (2013). https://doi.org/10.1007/s11661-012-1532-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1532-7