Abstract

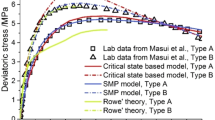

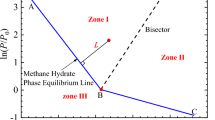

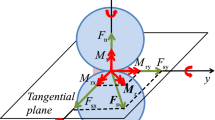

Macroscopic geomechanical properties of methane hydrate-bearing sands (MHBSs) have attracted much scholarly attention. But the associated particle-level mechanisms often rely on assumptions. In this paper, triaxial compression tests and numerical simulations using discrete element method (DEM) are combined to study the unique mechanical properties of MHBS at the particle scale. The triaxial compression tests understand the basic mechanical properties of MHBS, and the experiments results are used for DEM modeling and parameter calibration. Small cementing particles are used to simulate methane hydrate, showing dispersion and coalescence distributions in sediments to simulate different hydrate spatial distributions. The simulation results show that in MHBS samples, the increasing hydrate saturation enhances the cementation network as well as the hydrate-related micro-force chains, and the particles in the cementation network jointly share the loading. The hydrate cementation is restricted by the high effective confining pressure as the cementation network was subjected to an ultimate strength. For hydrate cementation failure, the high effective confining pressure increases the proportion of shear breakage, but tensile breakage is the dominant failure form. The sample with hydrate coalescence distribution behaves strain hardening, while the sample with hydrate dispersion distribution yields later and shows strain softening with a higher peak strength. Finally, the stress-induced anisotropy in microstructure fabrics is observed, and the development of radial fabrics is hindered by hydrates, especially the coalesced hydrates.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Arthur JRF, Menzies BK (1972) Discussion: Inherent anisotropy in a sand. Géotechnique 22:537–541. https://doi.org/10.1680/geot.1972.22.3.537

Brugada J, Cheng YP, Soga K, Santamarina JC (2010) Discrete element modelling of geomechanical behaviour of methane hydrate soils with pore-filling hydrate distribution. Granul Matter 12:517–525

Casagrande A, Carillo N (1944) Shear failure of anisotropic materials. In: Proceedings of the Boston Society of Civil Engineers

Chaouachi M, Falenty A, Sell K et al (2015) Microstructural evolution of gas hydrates in sedimentary matrices observed with synchrotron X-ray computed tomographic microscopy. Geochem Geophys Geosyst 16:1711–1722. https://doi.org/10.1002/2015GC005811

Chen B, Li K, Sun H et al (2022) Promoting effect of common marine cations on hydrate dissociation and structural evolution under a static electric field. J Phys Chem B. https://doi.org/10.1021/acs.jpcb.2c05382

Cheng F, Wu Z, Sun X et al (2023) Compression-induced dynamic change in effective permeability of hydrate-bearing sediments during hydrate dissociation by depressurization. Energy 264:126137. https://doi.org/10.1016/j.energy.2022.126137

Cohen E, Klar A, Yamamoto K (2019) Micromechanical investigation of stress relaxation in gas hydrate-bearing sediments due to sand production. Energies 12:2131. https://doi.org/10.3390/en12112131

Cundall PA (1989) Numerical experiments on localization in frictional materials. Ingenieur-Archiv 59:148–159. https://doi.org/10.1007/BF00538368

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Géotechnique 29:47–65. https://doi.org/10.1680/geot.1979.29.1.47

Dai S, Santamarina JC, Waite WF, Kneafsey TJ (2012) Hydrate morphology: physical properties of sands with patchy hydrate saturation. J Geophys Res B Solid Earth. https://doi.org/10.1029/2012JB009667

Ding Y, Qian A, Lu H et al (2022) DEM investigation of the effect of hydrate morphology on the mechanical properties of hydrate-bearing sands. Comput Geotech 143:104603. https://doi.org/10.1016/j.compgeo.2021.104603

Gao Z, Zhao J, Yao Y (2010) A generalized anisotropic failure criterion for geomaterials. Int J Solids Struct 47:3166–3185. https://doi.org/10.1016/j.ijsolstr.2010.07.016

Hong J, Xu M (2020) DEM study on the undrained mechanical behavior of gassy sand. Acta Geotech 15:2179–2193. https://doi.org/10.1007/s11440-019-00910-x

Hyodo M, Li Y, Yoneda J et al (2013) Mechanical behavior of gas-saturated methane hydrate-bearing sediments. J Geophys Res Solid Earth 118:5185–5194. https://doi.org/10.1002/2013JB010233

Hyodo M, Wu Y, Nakashima K et al (2017) Influence of fines content on the mechanical behavior of methane hydrate-bearing sediments. J Geophys Res Solid Earth 122:7511–7524. https://doi.org/10.1002/2017JB014154

Itasca Consulting Group Inc (2019) PFC—Particle Flow Code in 2 and 3 dimensions, Version 6.0, User’s Manual

Iwashita K, Oda M (1998) Rolling resistance at contacts in simulation of shear band development by DEM. Asce 124:285–292

Jiang M, Liu J, Shen Z (2019) DEM simulation of grain-coating type methane hydrate bearing sediments along various stress paths. Eng Geol 261:105280. https://doi.org/10.1016/j.enggeo.2019.105280

Jung JW, Santamarina JC (2011) Hydrate adhesive and tensile strengths. Geochem Geophys Geosyst 12:Q08003. https://doi.org/10.1029/2010GC003495

Kajiyama S, Wu Y, Hyodo M et al (2017) Experimental investigation on the mechanical properties of methane hydrate-bearing sand formed with rounded particles. J Nat Gas Sci Eng 45:96–107. https://doi.org/10.1016/j.jngse.2017.05.008

Le TX, Bornert M, Aimedieu P et al (2020) An experimental investigation on methane hydrate morphologies and pore habits in sandy sediment using synchrotron X-ray computed tomography. Mar Pet Geol 122:104646. https://doi.org/10.1016/j.marpetgeo.2020.104646

Lee SY, Holder GD (2001) Methane hydrates potential as a future energy source. Fuel Process Technol 71:181–186. https://doi.org/10.1016/S0378-3820(01)00145-X

Lei L, Seol Y (2020) Pore-scale investigation of methane hydrate-bearing sediments under triaxial condition. Geophys Res Lett 47:1–11. https://doi.org/10.1029/2019GL086448

Lei L, Seol Y, Choi JH, Kneafsey TJ (2019) Pore habit of methane hydrate and its evolution in sediment matrix—laboratory visualization with phase-contrast micro-CT. Mar Pet Geol 104:451–467. https://doi.org/10.1016/j.marpetgeo.2019.04.004

Lei L, Seol Y, Jarvis K (2018) Pore-scale visualization of methane hydrate-bearing sediments with micro-CT. Geophys Res Lett 45:5417–5426. https://doi.org/10.1029/2018GL078507

Li Y, Li J, You Z et al (2023) A particle-scale investigation of mechanical behavior of cemented hydrate-bearing sediment using Discrete Element Method. Geomech Energy Environ 33:100436. https://doi.org/10.1016/j.gete.2023.100436

Li C, Liu C, Hu G et al (2019) Investigation on the multiparameter of hydrate-bearing sands using nano-focus X-ray computed tomography. J Geophys Res Solid Earth 124:2286–2296. https://doi.org/10.1029/2018JB015849

Li Y, Wang L, Xie Y et al (2023) Deformation characteristics of methane hydrate-bearing clayey and sandy sediments during depressurization dissociation. Energy 275:127527. https://doi.org/10.1016/j.energy.2023.127527

Li Y, Wu P, Sun X, et al (2021) Mechanical behaviors of hydrate-bearing sediment with different cementation spatial distributions at microscales. iScience 24:102448. https://doi.org/10.1016/j.isci.2021.102448

Madhusudhan BN, Clayton CRI, Priest JA (2019) The effects of hydrate on the strength and stiffness of some sands. J Geophys Res Solid Earth 124:65–75. https://doi.org/10.1029/2018JB015880

Makogon YF (1965) Hydrate formation in the gas-bearing beds under permafrost conditions

Miyazaki K, Masui A, Sakamoto Y et al (2011) Triaxial compressive properties of artificial methane-hydrate-bearing sediment. J Geophys Res Solid Earth 116:1–11. https://doi.org/10.1029/2010JB008049

Nabeshima Y, Takai Y, Komai T (2005) Compressive strength and density of methane hydrate. In: Sixth ISOPE Ocean Min. Symp. ISOPE-M-05-036

Oda M (1982) Fabric tensor for discontinuous geological materials. Soils Found 22:96–108. https://doi.org/10.3208/sandf1972.22.4_96

Oda M, Koishikawa I, Higuchi T (1978) Experimental study of anisotropic shear strength of sand by plane strain test. Soils Found 18:25–38. https://doi.org/10.3208/sandf1972.18.25

Potyondy DO (2015) The bonded-particle model as a tool for rock mechanics research and application: current trends and future directions. Geosystem Eng 18:1–28

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364. https://doi.org/10.1016/j.ijrmms.2004.09.011

Radjai F, Wolf DE, Jean M, Moreau JJ (1998) Bimodal character of stress transmission in granular packings. Phys Rev Lett 80:61–64. https://doi.org/10.1103/PhysRevLett.80.61

Shen Z, Jiang M (2016) DEM simulation of bonded granular material. Part II: extension to grain-coating type methane hydrate bearing sand. Comput Geotech 75:225–243. https://doi.org/10.1016/j.compgeo.2016.02.008

Shen S, Li Y, Sun X et al (2021) Analysis of the mechanical properties of methane hydrate-bearing sands with various pore pressures and confining pressures. J Nat Gas Sci Eng 87:103786. https://doi.org/10.1016/j.jngse.2020.103786

Shen S, Li Y, Sun X et al (2022) Mechanical properties of methane hydrate-bearing sandy sediments under various temperatures and pore pressures. J Pet Sci Eng 208:109474. https://doi.org/10.1016/j.petrol.2021.109474

Shen S, Sun X, Wang L et al (2021) Effect of temperature on the mechanical properties of hydrate-bearing sand under different confining pressures. Energy Fuels 35:4106–4117. https://doi.org/10.1021/acs.energyfuels.1c00052

Sloan ED (2003) Fundamental principles and applications of natural gas hydrates. Nature 426:353–359. https://doi.org/10.1038/nature02135

Sun X, Luo T, Wang L et al (2019) Numerical simulation of gas recovery from a low-permeability hydrate reservoir by depressurization. Appl Energy 250:7–18. https://doi.org/10.1016/j.apenergy.2019.05.035

Thornton C (2000) Numerical simulations of deviatoric shear deformation of granular media. Geotechnique 50:43–53. https://doi.org/10.1680/geot.2000.50.1.43

Vinod JS, Hyodo M, Indraratna B, Kajiyama S (2015) Shear behaviour of methane hydrate bearing sand: DEM simulations. In: Geomech from Micro to Macro—Proc TC105 ISSMGE Int Symp Geomech from Micro to Macro, IS-Cambridge 2014, vol 1, pp 355–359. https://doi.org/10.1201/b17395-63

Waite WF, Santamarina JC, Cortes DD et al (2009) Physical properties of hydrate-bearing sediments. Rev Geophys 47:RG4003. https://doi.org/10.1029/2008RG000279

Waite WF, Winters WJ, Mason DH (2004) Methane hydrate formation in partially water-saturated Ottawa sand. Am Mineral 89:1202–1207. https://doi.org/10.2138/am-2004-8-906

Wang H, Chen Y, Zhou B, Xue S (2021) Investigation of the effect of cementing ratio on the mechanical properties and strain location of hydrate-bearing sediments by using DEM. J Nat Gas Sci Eng 94:104123. https://doi.org/10.1016/j.jngse.2021.104123

Wang YH, Leung SC (2008) A particulate-scale investigation of cemented sand behavior. Can Geotech J 45:29–44. https://doi.org/10.1139/T07-070

Wang H, Liu W, Wu P et al (2023) Gas recovery from marine hydrate reservoir: experimental investigation on gas flow patterns considering pressure effect. Energy 275:127482. https://doi.org/10.1016/j.energy.2023.127482

Wang L, Sun X, Shen S et al (2021) Undrained triaxial tests on water-saturated methane hydrate-bearing clayey-silty sediments of the south China sea. Can Geotech J 58:351–366. https://doi.org/10.1139/cgj-2019-0711

Wang H, Wu P, Li Y et al (2023) Gas permeability variation during methane hydrate dissociation by depressurization in marine sediments. Energy 263:125749. https://doi.org/10.1016/j.energy.2022.125749

Wu P, Li Y, Liu W et al (2020) Cementation failure behavior of consolidated gas hydrate-bearing sand. J Geophys Res Solid Earth 125:1–19. https://doi.org/10.1029/2019JB018623

Wu P, Li Y, Wang L et al (2022) Hydrate-bearing sediment of the South China Sea: Microstructure and mechanical characteristics. Eng Geol 307:106782. https://doi.org/10.1016/j.enggeo.2022.106782

Wu P, Li Y, Yu T et al (2023) Microstructure evolution and dynamic permeability anisotropy during hydrate dissociation in sediment under stress state. Energy 263:126126. https://doi.org/10.1016/j.energy.2022.126126

Xu M, Song E, Jiang H, Hong J (2016) DEM simulation of the undrained shear behavior of sand containing dissociated gas hydrate. Granul Matter 18:1–13. https://doi.org/10.1007/s10035-016-0675-4

Yan RT, Wei CF, Wei HZ et al (2012) Effect of hydrate formation on mechanical strength of hydrate-bearing sand. Chin J Geotech Eng 34:1234–1240

Yang L, Liu Y, Zhang H et al (2019) The status of exploitation techniques of natural gas hydrate. Chin J Chem Eng 27:2133–2147. https://doi.org/10.1016/j.cjche.2019.02.028

Yang L, Zhao J, Liu W et al (2015) Microstructure observations of natural gas hydrate occurrence in porous media using microfocus X-ray computed tomography. Energy Fuels 29:4835–4841. https://doi.org/10.1021/acs.energyfuels.5b00881

Yoneda J, Jin Y, Katagiri J, Tenma N (2016) Strengthening mechanism of cemented hydrate-bearing sand at microscales. Geophys Res Lett 43:7442–7450. https://doi.org/10.1002/2016GL069951

Yoneda J, Kida M, Konno Y et al (2019) In situ mechanical properties of shallow gas hydrate deposits in the deep seabed. Geophys Res Lett 46:14459–14468. https://doi.org/10.1029/2019GL084668

You Z, Li Y, Jiang M et al (2021) A numerical investigation on the mechanical properties of hydrate-bearing sand using Distinct Element Method. J Nat Gas Sci Eng 96:104328. https://doi.org/10.1016/j.jngse.2021.104328

You Z, Wu P, Sun X et al (2022) Effect of hydrate distribution on the mechanical response of hydrate-bearing sand: discrete element method simulation. Energy Fuels 36:3802–3815. https://doi.org/10.1021/acs.energyfuels.2c00122

Yu Y, Cheng YP, Xu X, Soga K (2016) Discrete element modelling of methane hydrate soil sediments using elongated soil particles. Comput Geotech 80:397–409. https://doi.org/10.1016/j.compgeo.2016.03.004

Yu Y, Xu X, Cheng YP, Soga K (2013) Study on small-strain behaviours of methane hydrate sandy sediments using discrete element method. AIP Conf Proc 1542:555–558. https://doi.org/10.1063/1.4811991

Yun TS, Santamarina CJ, Ruppel C (2007) Mechanical properties of sand, silt, and clay containing tetrahydrofuran hydrate. J Geophys Res Solid Earth 112:1–13. https://doi.org/10.1029/2006JB004484

Zhang A, Dafalias YF, Jiang M (2021) A bounding surface plasticity model for cemented sand under monotonic and cyclic loading. Géotechnique. https://doi.org/10.1680/jgeot.20.p.275

Zhang XH, Lu XB, Shi YH, Xia Z (2015) Study on the mechanical properties of hydrate-bearing silty clay. Mar Pet Geol 67:72–80. https://doi.org/10.1016/j.marpetgeo.2015.04.019

Zhao Y, Konietzky H, Herbst M (2021) Damage evolution of coal with inclusions under triaxial compression. Rock Mech Rock Eng 54:5319–5336. https://doi.org/10.1007/s00603-021-02436-9

Zhao Z, Song EX (2015) Particle mechanics modeling of creep behavior of rockfill materials under dry and wet conditions. Comput Geotech 68:137–146. https://doi.org/10.1016/j.compgeo.2015.04.008

Zhao J, Yang L, Liu Y, Song Y (2015) Microstructural characteristics of natural gas hydrates hosted in various sand sediments. Phys Chem Chem Phys 17:22632–22641. https://doi.org/10.1039/c5cp03698d

Zhou S, Zhao J, Li Q et al (2018) Optimal design of the engineering parameters for the first global trial production of marine natural gas hydrates through solid fluidization. Nat Gas Ind B 5:118–131. https://doi.org/10.1016/j.ngib.2018.01.004

Acknowledgements

This research was funded by the National Natural Science Foundation of China (Grants 51890911, U20B6005 and 52222608) and the LiaoNing Revitalization Talents Program (Grant XLYC2007099).

Author information

Authors and Affiliations

Contributions

Investigation, Methodology, Visualization and Writing—original draft: ZY; Conceptualization, Funding acquisition and Writing—review & editing: YL; Formal analysis and Investigation: HW; Methodology: XS; Validation: SS; Writing—review & editing: PW; Project administration and Supervision: YS.

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

You, Z., Li, Y., Wang, H. et al. A particle-scale study of the triaxial compression behavior of methane hydrate-bearing sands. Acta Geotech. (2023). https://doi.org/10.1007/s11440-023-02043-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11440-023-02043-8