Abstract

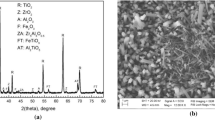

The isothermal oxidation behaviour of a titanium ATI425® alloy was studied in dry air at 850, 900, and 1000 °C. The parabolic rate law described the oxidation kinetics; the mass gained increasing when the temperature of the tests increased. The activation energy for the process was 120 kJ/mol. This value was comparable to the activation energy calculated for oxygen dissolution within the metal and the activation energy value for the oxidation of other titanium alloys. Oxygen dissolution within the metallic matrix resulted in the formation of an alpha case region whose thickness and hardness were also a function of the temperature of the tests. The chemical composition of the oxides changed from a scale comprised mainly by rutile TiO2 at the lowest test temperature to a layer consisting of a mixture of rutile TiO2 and non-protective alumina Al2O3 clusters when the temperature of the tests increased. The oxide structures formed on the surface of the alloy were also a function of the temperature and changed from a morphology comprised of small crystals at 850 °C to bar, platelets, and whiskers when oxidation occurred at 900 and 1000 °C. The oxidation rate of the alloy was compared against kinetics values reported for the Ti-6Al-4 V system, resulting in similar oxidation rates.

Similar content being viewed by others

References

Y. Qu, M. Wang, L. Lei, X. Huang, L. Wang, J. Qin, W. Lu, and D. Zhang, Behavior and modeling of high temperature deformation of an α+ β titanium alloy. Materials Science and Engineering: A 555, 2012 (99–105).

H. Garbacz and M. Lewandowska, Microstructural changes during oxidation of titanium alloys. Materials Chemistry and Physics 81, (2–3), 2003 (542–547).

P. Kofstad, P. B. Anderson, and O. J. Krudtaa, Oxidation of titanium in the temperature range 800–1200 C. Journal of the Less-Common Metals 3, (2), 1961 (89–97).

P. Kofstad, High-temperature oxidation of titanium. Journal of the Less-Common Metals 12, (6), 1967 (449–464).

G. K. J. M. Bertrand, K. Jarraya, and J. M. Chaix, Morphology of oxide scales formed on titanium. Oxidation of metals 21, (1), 1984 (1–19).

F. Pitt and M. Ramulu, Influence of grain size and microstructure on oxidation rates in titanium alloy Ti-6Al-4V under superplastic forming conditions. Journal of Materials Engineering and Performance 13, (6), 2004 (727–734).

D. S. P. J. Eylon, S. Fujishiro, P. J. Postans, and F. H. Froes, High-temperature titanium alloys—a review. J.O.M. 36, (11), 1984 (55–62).

E. Dong, W. Yu, Q. Cai, L. Cheng, and J. Shi, High-temperature oxidation kinetics and behavior of Ti–6Al–4V alloy. Oxidation of Metals 88, (5), 2017 (719–732).

C. Dupressoire, A. R. V. Put, P. Emile, C. Archambeau-Mirguet, R. Peraldi, and D. Monceau, Effect of nitrogen on the kinetics of oxide scale growth and oxygen dissolution in the Ti6242S titanium-based alloy. Oxidation of Metals 87, (3–4), 2017 (343–353).

Bryan, D., 2014. A.T.I. 425® Alloy Formability: Theory and Application. In Materials Science Forum (Vol. 783, pp. 543–548). Trans Tech Publications Ltd.

K. Gangwar, M. Ramulu, A. Cantrell, and D. G. Sanders, Microstructure and mechanical properties of friction stir welded dissimilar titanium alloys: TIMET-54M and ATI-425. Metals 6, (10), 2016 (252).

Q. Meng, C. Bai, and D. Xu, Flow behavior and processing map for hot deformation of ATI425 titanium alloy. Journal of materials science & technology 34, (4), 2018 (679–688).

S. Y. Sung and Y. J. Kim, Alpha-case formation mechanism on titanium investment castings. Materials Science and Engineering: A 405, (1–2), 2005 (173–177).

E. V. Naydenkin, I. P. Mishin, I. V. Ratochka, O. N. Lykova, and O. V. Zabudchenko, The effect of alpha-case formation on plastic deformation and fracture of near β titanium alloy. Materials Science and Engineering: A. 2, (769), 2020 (138495).

Uwanyuze, S., Kanyo, J., Myrick, S., and Schafföner, S., 2021. A review on alpha case formation and modeling of mass transfer during investment casting of titanium alloys. Journal of Alloys and Compounds, p.158558.

F. A. Pérez-González, N. F. Garza-Montes-de Oca, and R. Colás, High temperature oxidation of the Haynes 282© nickel-based superalloy. Oxidation of metals 82, (3), 2014 (145–161).

F. A. Pérez-González, J. H. Ramírez-Ramírez, M. Terock, N. F. Garza-Montes-de-Oca, U. Glatzel, and R. Colás, High-temperature oxidation of a nickel base superalloy at different oxygen partial pressures. Corrosion Engineering, Science and Technology 51, (7), 2016 (513–521).

P. J. Bania, Beta titanium alloys and their role in the titanium industry. Jom 46, (7), 1994 (16–19).

R. Gaddam, B. Sefer, R. Pederson, and M. L. Antti, Oxidation and alpha-case formation in Ti–6Al–2Sn–4Zr–2Mo alloy. Materials Characterization 99, 2015 (166–174).

Valdés-Saucedo, O.A., Vázquez-Rodríguez, L.J., López-Zárate, B., Garza-Tovar, L., García-Gómez, N.A., Artigas, A., Monsalve, A., Ramírez-Ramírez, J.H.H., Pérez-González, F.A., Colás, R. and Garza-Montes-de-Oca, N.F., 2018. High temperature isothermal and cyclic oxidation behaviour of pure recycled titanium. Anti-Corrosion Methods and Materials.

O. Kubaschewski and B. E. Hopkins, Oxidation of metals and alloys, (Butterworths, 1967).

N. Vaché and D. Monceau, Oxygen diffusion modeling in titanium alloys: new elements on the analysis of microhardness profiles. Oxidation of Metals 93, (1), 2020 (215–227).

R. N. Shenoy, J. Unnam, and R. K. Clark, Oxidation and embrittlement of Ti-6Al-2Sn-4Zr-2Mo alloy. Oxidation of metals 26, (1), 1986 (105–124).

R. W. Evans, R. J. Hull, and B. Wilshire, The effects of alpha-case formation on the creep fracture properties of the high-temperature titanium alloy IMI834. Journal of materials processing technology 56, (1–4), 1996 (492–501).

C. Leyens, M. Peters, D. Weinem, and W. A. Kaysser, Influence of long-term annealing on tensile properties and fracture of near-α titanium alloy Ti-6Al-2.75 Sn-4Zr-0.4 Mo-0.45 Si. Metallurgical and Materials Transactions A 27, (6), 1996 (1709–1717).

N. F. Garza-Montes-de-Oca, J. H. Ramírez-Ramírez, I. Alvarez-Elcoro, W. M. Rainforth, and R. Colás, Oxide structures formed during the high temperature oxidation of hot mill work rolls. Oxidation of metals 80, (1), 2013 (191–203).

N. W. Ashcroft and N. D. Mermin, Solid State Physics, Chapter 30, (CA, Brooks/Cole Belmont, 1976), p. 637.

N. Birks, G. H. Meier, and F. S. Pettit, Introduction to the high-temperature oxidation of metals, (Cambridge University Press, 2006).

J. Dai, J. Zhu, C. Chen, and F. Weng, High-temperature oxidation behavior and research status of modifications on improving high-temperature oxidation resistance of titanium alloys and titanium aluminides: A review. Journal of Alloys and Compounds 685, 2016 (784–798).

Hasegawa, M. (2014). Ellingham diagram. In Treatise on Process Metallurgy (pp. 507–516). Elsevier.

A. Rahmel and P. J. Spencer, Thermodynamic aspects of TiAl and TiSi2 oxidation: the Al-Ti-O and Si-Ti-O phase diagrams. Oxidation of Metals 35, (1), 1991 (53–68).

Y. S. Chen and C. J. Rosa, High-temperature oxidation of Ti-4.32 wt.% Nb alloy. Oxidation of Metals 14, (2), 1980 (147–165).

Acknowledgments

The authors would like to thank the National Council for Science and Technology of Mexico (C.O.N.A.C.Y.T.), the lecturer development program (P.R.O.D.E.P.), and Universidad Autónoma de Nuevo León for the facilities provided to develop this investigation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Valdés-Saucedo, O.A., Rocha-Moreno, R.C., Ramírez-Ramírez, J.H. et al. Characterization of the High Temperature Isothermal Oxidation Behaviour of an ATI425® Titanium Alloy. Oxid Met 95, 427–444 (2021). https://doi.org/10.1007/s11085-021-10032-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-021-10032-z