Abstract

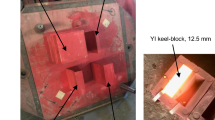

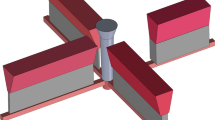

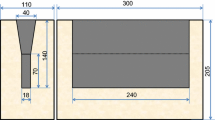

The use of high silicon ductile irons is increasing as they offer some advantages with respect to conventional pearlitic–ferritic grades such as high elongation at rupture for a given tensile strength value and a fully ferritic matrix. Besides addressing mechanical requirements, some castings must fulfil corrosion and high-temperature oxidation requisites. Two different ductile cast irons with silicon contents of 2.04 and 5.21 wt% were used so as to comparatively study their mechanical properties and high-temperature oxidation responses. The structure of both alloys contains nodular graphite and a fully ferritic matrix. Some samples of the alloy with 5.21 wt% silicon also contain abundant degenerated graphite which was identified as Chunky graphite. Oxidation resistance of both materials was evaluated by exposures to air at 650 °C for 720 h using a tubular furnace. The alloy with 5.21 wt% silicon showed an oxidation resistance about three times higher than the low silicon alloy. Although both alloys showed similar oxidation mechanisms, the oxidation scale formed on the high-silicon alloy stands out for having lower thickness, higher silicon content in the metal/oxide interface and more compact and adherent layers. Samples with Chunky graphite showed a similar evolution to those with graphite nodules, so no negative effect from this graphite degeneration on oxidation process was observed. The analyses performed by XRD revealed the presence of fayalite in the 5.21 wt% Si alloy, which is responsible for the better oxidation resistance.

Graphical Abstract

Similar content being viewed by others

References

G. Toktas, A. Toktas and M. Tayanc, Materials and Design 29, 1600–1608 (2008). https://doi.org/10.1016/j.matdes.2007.10.001.

N. S. Tiedje, Materials Science and Technology 26, 505–514 (2010). https://doi.org/10.1179/026708310X12668415533649.

R. Kallbörn, K. Hamberg, M. Wessén and L. E. Björkegren, Materials Science and Engineering A 413–414, 346–351 (2005). https://doi.org/10.1016/j.msea.2005.08.210.

M. Shirani and G. Härkegård, Engineering Failure Analysis 18, 12–24 (2011). https://doi.org/10.1016/j.engfailanal.2010.07.001.

C. Labrecque and M. Gagné, Canadian Metallurgical Quarterly 37, 343–378 (1998). https://doi.org/10.1179/cmq.1998.37.5.343.

A. Suárez-Sanabria and J. Fernández-Carrasquilla, Revista de Metalurgia 42, 18–31 (2006).

M. Sancy, Y. Gourbeyre, E. M. M. Sutter and T. Tribollet, Corrosion Science 52, 1222–1227 (2010). https://doi.org/10.1016/j.corsci.2009.12.026.

M. A. Arenas, A. Niklas, A. Conde, S. Méndez, J. Sertucha, J. de Damborenea, Revista de Metalurgia 50 (2014). http://dx.doi.org/10.3989/revmetalm.032.

A. Ebel, S. Y. Brou, B. Malard, J. Lacaze, D. Monceau and L. Vaissière, Materials Science Forum 925, 353–360 (2018). https://doi.org/10.4028/www.scientific.net/MSF.925.353.

K.-A. Jafar and A.-A. Behnam, Journal of Iron and Steel Research, International 18, 34–39 (2011). https://doi.org/10.1016/S1006-706X(11)60034-4.

R. González-Martínez, U. de la Torre, J. Lacaze and J. Sertucha, Materials Science and Engineering A 712, 794–802 (2018). https://doi.org/10.1016/j.msea.2017.11.050.

U. de la Torre, A. Loizaga, J. Lacaze and J. Sertucha, Materials Science and Technology 30, 1425–1431 (2014). https://doi.org/10.1179/1743284713Y.0000000483.

J. Lacaze, L. Magnusson-Åberg, J. Sertucha J, Review of microstructural features of chunky graphite in ductile cast irons. Proceedings of the Keith Millis symposium, Nashville, American Foundry Society (2013), pp. 360–368.

U. de la Torre, J. Lacaze and J. Sertucha, International Journal of Materials Research 107, 1041–1050 (2017). https://doi.org/10.3139/146.111434.

P. A. Schweitzer, Fundamentals of metallic corrosion: atmospheric and media corrosion of metals. Chapter 4, Corrosion of Cast Iron and Cast Steel (CRC Press, 2006).

Z. Glavas, A. Strkalj and A. Stojakovich, Metalurgija 55, 293–296 (2016).

W. Stets, H. Löblich, G. Gassner and P. Schumacher, International Journal of Metalcasting 8, 35–40 (2014). https://doi.org/10.1007/BF03355580.

R. González-Martínez, U. de la Torre, A. Ebel, J. Lacaze and J. Sertucha, Materials Science and Engineering A 712, 803–811 (2018). https://doi.org/10.1016/j.msea.2017.11.051.

A. Reynaud, Elsevier 3, 2010 (1737–1788).

A. K. Gupta, D. Boruah, N. Suresh, N. Kamal, A. K. Singh, International Journal of Engineering Research and Applications 6, 68–73 (2016) ISSN: 2248-9622.

P. M. Dardati, D. J. Celentano, L. A. Godoy, A. A. Chiarella and B. J. Schulz, International Journal of Cast Metals Research 22, 390–400 (2009). https://doi.org/10.1179/174313309X436646.

R. Källbom, K. Hamberg, L.-E. Björkegren, Chunky graphite in ductile iron castings. Proceedings of 67th World Foundry Congress, Harrogate, UK. 2006.

X. G. Diao, Z. L. Ning, F. Y. Cao, S. Z. Ren and J. F. Sun, Materials Science and Technology 27, 834–838 (2011). https://doi.org/10.1179/026708309X12560332736557.

A. Mourujärvi, K. Widell, T. Saukkonen and H. Hänninen, Fatigue and Fracture of Engineering Materials and Structures 32, 379–390 (2009). https://doi.org/10.1111/j.1460-2695.2009.01337.x.

P. Ferro, P. Lazzrin and F. Berto, Materials Science and Engineering A 554, 122–128 (2012). https://doi.org/10.1016/j.msea.2012.06.024.

J. Kaczorowski and K. Jozwiak, Journal of Failure Analysis and Prevention 13, 446–450 (2013). https://doi.org/10.1007/s11668-013-9693-2.

I. Svedung and N. G. Vannerberg, Corrosion Science 14, 391–399 (1974).

M. Ekström, P. Szakalos and S. Jonsson, Oxidation of Metals 80, 455–466 (2013). https://doi.org/10.1007/s11085-013-9389-8.

M. M. P. Brady, G. Muralidharan, D. N. Leonard, J. A. Haynes, R. G. Weldon and R. D. England, Oxidation of Metals 82, 359–381 (2014). https://doi.org/10.1007/s11085-014-9496-1.

M.-B. Lin, C.-J. Wang and A. A. Volinsky, Oxidation of Metals 76, 161–168 (2011). https://doi.org/10.1007/s11085-011-9244-8.

F. Tholence and M. Norell, Oxidation of Metals 69, 13–36 (2008).

Z. Ban, K. Bohnenkamp and H.-J. Engell, Corrosion Science 19, 283–293 (1979).

C. R. Cvetnic, C. Ravindran and A. McLean, Canadian Metallurgical Quarterly 46, 75–88 (2007).

A. Atkinson, Corrosion Science 22, 87–102 (1982).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Méndez, S., Arenas, M.Á., Niklas, A. et al. Effect of Silicon and Graphite Degeneration on High-Temperature Oxidation of Ductile Cast Irons in Open Air. Oxid Met 91, 225–242 (2019). https://doi.org/10.1007/s11085-018-9875-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-018-9875-0