Abstract

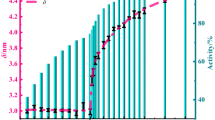

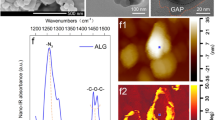

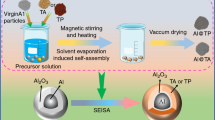

Energetic fluoride chemistry possesses great promise as the energetic fluoride coating has the potential to enhance energy release of aluminum. In this study, glycidyl azide polymer (GAP) and pentadecafluorooctanoic acid (PFOA) were one-pot esterified to form energetic fluoride: glycidyl azide polymer pentadecafluorooctanoic ester (GAPFE), which formed homogeneous coating on the surface of micron-sized Al to form Al@GAPFE. The exothermic enthalpy of Al@GAPFE in the DSC test was 2.5 times higher than that of raw Al. Al@GAPFE not only effectively lowering ignition temperature, but also enhanced the combustion heat by 6.2%. The promotive effect of GAPFE on ignition and combustion was outstanding among the reported aluminum fuels. Our work provided an effective synthetic strategy for one-pot energetic fluoride chemistry, which addressed potential use in propellants, explosives, protective coating, multifunctional interface, etc. Besides, the corresponding combustion and exothermic mechanisms were also discussed in details, which could help the future design of high-performance energetic materials.

Similar content being viewed by others

References

Wang C, Zou X, Yin S, Wang J, Li H, Liu Y, et al. Improvement of ignition and combustion performance of micro-aluminum particles by double-shell nickel-phosphorus alloy coating. Chem Eng J. 2021;1:133585.

Jiang Y, Deng S, Hong S, Zhao J, Huang S, Wu CC, et al. Energetic performance of optically activated aluminum/graphene oxide composites. ACS Nano. 2018;12(11):11366–75.

Qiu Q, Zhou Y, Liu J, Shi W, Yang W. Combustion of aluminum powder using CO2 laser in O2/CO2 atmosphere under different pressure conditions. J Therm Anal and Calorim. 2021;147(8):4959–70.

Zhou Y, Liu J, Li H, Yuan J, Zhou J. Combustion of aluminum particles in a high-temperature furnace under various O2/CO2/H2O atmospheres. J Therm Anal Calorim. 2019;139(1):251–60.

Xiao F, Liu Z, Liang T, Yang R, Li J, Luo P. Establishing the interface layer on the aluminum surface through the self-assembly of tannic acid (TA): Improving the ignition and combustion properties of aluminum. Chem Eng J. 2021;420:130523.

Wang J, Qiao Z, Yang Y, Shen J, Long Z, Li Z, et al. Core-Shell Al-polytetrafluoroethylene (PTFE) configurations to enhance reaction kinetics and energy performance for nanoenergetic materials. Chemistry. 2016;22(1):279–84.

Li Y, Ren H, Yan T, Jiao Q, Wang H. Reactivity of fluororubber-modified aluminum in terms of heat transfer effect. J Therm Anal Calorim. 2020;142(2):871–6.

Piao J, Duan S, Mao Y, Wang J, Cao A-M, Zhang L. Stabilization of the energetic Al powder through uniform and controlled surface coating for promoting its energy output. Surf Coat Technol. 2020;389:12603.

Hu Y, Hao D, Tao B, Wang F, Wang D, Fan R, et al. Core-shell nAl@Fc-Fx nanocomposites with dual function: combustion and anti-migration performance. Chem Eng J. 2020;394:124884.

Li Y, Li J, Wang B, Ma H, Han Z. An approach to the induced reaction mechanism of the combustion of the nano-Al/PVDF composite particles. Surf Coat Technol. 2022;429:127912.

Osborne DT, Pantoya ML. Effect of Al particle size on the thermal degradation of al/teflon mixtures. Combust Sci Technol. 2007;179(8):1467–80.

DeLisio JB, Hu X, Wu T, Egan GC, Young G, Zachariah MR. Probing the reaction mechanism of aluminum/poly(vinylidene fluoride) composites. J Phys Chem B. 2016;120(24):5534–42.

Li Z, Zhao X, Li G, Gong F, Liu Y, Yan Q, et al. Surface fluorination of n-Al particles with improved combustion performance and adjustable reaction kinetics. Chem Eng J. 2021;425:131619.

Nie H, Pisharath S, Hng HH. Combustion of fluoropolymer coated Al and Al–Mg alloy powders. Combust Flame. 2020;220:394–406.

McCollum J, Pantoya ML, Iacono ST. Activating aluminum reactivity with fluoropolymer coatings for improved energetic composite combustion. ACS Appl Mater Interfaces. 2015;7(33):18742–9.

Jiang Y, Deng S, Hong S, Tiwari S, Chen H, Nomura KI, et al. Synergistically Chemical and Thermal Coupling between Graphene Oxide and Graphene Fluoride for Enhancing Aluminum Combustion. ACS Appl Mater Interf. 2020;12(6):7451–8.

Ao W, Liu P, Liu H, Wu S, Tao B, Huang X, et al. Tuning the agglomeration and combustion characteristics of aluminized propellants via a new functionalized fluoropolymer. Chem Eng J. 2020;382:122987.

He W, Lyu J-Y, Tang D-Y, He G-Q, Liu P-J, Yan Q-L. Control the combustion behavior of solid propellants by using core-shell Al-based composites. Combust Flame. 2020;221:441–52.

Ou Y, Jiao Q, Li N, Yan S, Yang R. Pyrolysis of ammonium perfluorooctanoate (APFO) and its interaction with nano-aluminum. Chem Eng J. 2021;403:126367.

Tang C-J, Lee Y, Litzinger TA. Simultaneous temperature and species measurements of the glycidyl azide polymer (GAP) propellant during laser-induced decomposition. Combust Flame. 1999;117(1):244–56.

Zeng C, Wang J, He G, Huang C, Yang Z, Liu S, et al. Enhanced water resistance and energy performance of core–shell aluminum nanoparticles via in situ grafting of energetic glycidyl azide polymer. J Mater Sci. 2018;53(17):12091–102.

Yan T, Ren H, Li Y, Wang H, Jiao Q. Tailoring structural energetics for enhanced reactivity of nano-aluminum particles based microspheres. Adv Eng Mater. 2019;21:1900176.

Zhang L, Su X, Wang S, Li X, Zou M. In situ preparation of Al@3-Perfluorohexyl-1, 2-epoxypropane@glycidyl azide polymer (Al@PFHP@GAP) high-energy material. Chem Eng J. 2022;45:137118.

Köthe M, Müller M, Simon F, Komber H, Adler HJ. Examination of poly(butadiene epoxide)-coatings on inorganic surfaces. Colloids Surfaces A. 1999;154(1–2):75–85.

Fredericks JR, Hamilton AD. Chem inform abstract: metal template control of self-assembly in supramolecular chemistry. Cheminform. 1997;3:1–39.

Sadeghipour S, Ghaderian J, Wahid MA. Advances in aluminum powder usage as an energetic material and applications for rocket propellant. 2012. p. 100–8.

Manship TD, Heister SD, O’Neil PT. Experimental investigation of high-burning-rate composite solid propellants. J Propul Power. 2012;28(6):1389–98.

Li MH. Effects of nonionic and ionic surfactants on survival, oxidative stress, and cholinesterase activity of planarian. Chemosphere. 2008;70(10):1796–803.

Zhu Z, Li S, Liu R, Yuan J, Wang H, Zhang Y, et al. Regio-and stereo-selective synthesis of peracetylated carbohydrate esters of aromatic fatty acid using p-toluenesulfonic acid as catalyst. Chinese J Chem. 2010;28(11):2245–8.

Bradley S, Moore P A. Non-stick natural products. Nat Chem. 2014;6(1):10–2.

Lee SW, Sigmund WM. Repulsive van der Waals Forces for Silica and Alumina. J Colloid Interf Sci. 2001;243(2):365–9.

Brown EN, Rae PJ, Orler EB, Iii G, Dattelbaum DM. The effect of crystallinity on the fracture of polytetrafluoroethylene (PTFE). Mater Sci Eng C. 2006;26(8):1338–43.

Liu Y, Wang P, Su X, Xu L, Tian Z, Wang H, et al. Electrically Programmable Interfacial Adhesion for Ultrastrong Hydrogel Bonding. Adv Mater. 2022;34(13):2108820.

Inamoto N, Masuda S. Revised Method for Calculation of Group Electronegativites. Chem Lett. 1982;11(7):1003–6.

Socrates G. Infrared and Raman characteristic group frequencies: tables and charts. USA: John Wiley & Sons; 2004.

Wang X, Wang W, Liu Y, Ren M, Xiao H, Liu X. Characterization of Conformation and Locations of C-F Bonds in Graphene Derivative by Polarized ATR-FTIR. Anal Chem. 2016;88(7):3926–34.

Ganie K, Mohshim DF, Saaid IM, Sulaiman WRW, Idris AK. Synthesis and characterization of a new surface-modified nanoparticle using fluoroalkanoic acids as a wettability alteration agent. J Nanomater. 2020;2020:1–9.

Hao D, Hu Y, Wang F, Xia D, Wang D, Fan R, et al. Core-shell structured nAl@F-x nanocomposite: preparation and their improved combustion performances. J Energ Mater. 2020;40:1–21.

Kim DW, Kim KT, Min TS, Kim KJ, Kim SH. Improved energetic-behaviors of spontaneously surface-mediated al particles. Sci Rep. 2017;7(1):4659.

Zhang G, Colin M, Yang X, Sun S, Dodelet J-P, Dubois M. C F bonding in fluorinated N-Doped carbons. Appli Surf Sci. 2022;577:151721.

Zhang L, Yi D, Hao J. Poly (diallyldimethylammonium) and polyphosphate polyelectrolyte complexes as an all-in-one flame retardant for polypropylene. Polym Advan Technol. 2019;31(2):260–72.

Kloprogge JT, Duong LV, Wood BJ, Frost RL. XPS study of the major minerals in bauxite: gibbsite, bayerite and (pseudo-)boehmite. J Colloid Interface Sci. 2006;296(2):572–6.

Pelissier B, Fontaine H, Beaurain A, Danel A, Joubert O. HF contamination of 200mm Al wafers: a parallel angle resolved XPS study. Microelectron Eng. 2011;88(6):861–6.

Lindsay JR, Rose HJ, Swartz WE, Watts PH, Rayburn KA. X-Ray photoelectron spectra of aluminum oxides: structural effects on the “chemical shift.” Appli Spectrosc. 1973;27(1):1–5.

Arisawa H, Brill TB. Thermal decomposition of energetic materials 71: structure-decomposition and kinetic relationships in flash pyrolysis of Glycidyl Azide Polymer (GAP). Combust Flame. 1998;112(4):533–44.

Zhang L, Liu Z, Wang X, Heng S, Pan Q, Zhao F. Investigation on thermal decomposition of GAP by FTIR spectroanalysis. J Solid Rocket Technol. 2010;5:549–53.

Zhou X-Y, Xiao F, Yang R-J, Huang F-L, Li J-M. Investigation of the ignition and combustion of compressed aluminum/polytetrafluoroethylene bulk composites. J Therm Anal Calorim. 2019;139(5):3013–21.

Salem S, Salem A, Parni MH, Jafarizad A. Facile and rapid auto-combustion synthesis of nano-porous γ-Al2O3 by application of hexamethylenetetramine in fuel composition. J Phys Chem Solids. 2018;117:86–93.

Acknowledgements

There is no other financial support for this work.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

10973_2023_12155_MOESM1_ESM.docx

The data of density and composition of samples (Table S1); FTIR spectra of GAP, PFOA and GAPFE; 1H NMR spectra of GAP, PFOA and GAPFE; EDS images of Al@PFOA and Al@GAPFE; Volume weighted particle size distributions of Al, Al@PFOA and Al@GAPFE; FTIR spectra of Al, Al@PFOA, Al@GAPFE; The XRD patterns of Al powders, Al@PFOA and Al@GAPFE; Thermal decomposition curve of GAPFE; Supplementary caption of Fig. 4. (DOCX 4775 KB)

Supplementary file2 (MP4 7880 KB)

Supplementary file3 (MP4 7189 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, L., Li, X., Wang, S. et al. Facile energetic fluoride chemistry induced organically coated aluminum powder with effectively improved ignition and combustion performances. J Therm Anal Calorim 148, 5957–5966 (2023). https://doi.org/10.1007/s10973-023-12155-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12155-8