Abstract

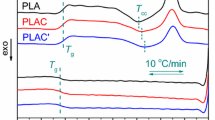

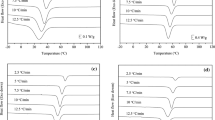

The effect of cellulose nanocrystal (CNC) content on the crystallization and melting behaviors of polylactide (PLA)/CNC nanocomposites prepared by solution mixing was investigated. Isothermal and non-isothermal cold crystallization kinetics of specimens were quantified using Ozawa, Avrami, and Liu-Mo methods. Overall and conversion dependent crystallization activation energy values were also determined through the Kissinger and Flynn–Wall–Ozawa equations. It was found that although CNC acted as a nucleating agent for cold crystallization of PLA under isothermal and non-isothermal conditions, it differently affected the crystal growth behavior. Kinetic calculations revealed that the increase in CNC amount decreased the non-isothermal cold crystallization rate of PLA possibly due to the reduced interaction among PLA molecules and formation of strong hydrogen bonding between the carboxyl groups of PLA and CNC surfaces. CNC addition also increased the overall cold crystallization activation energy whereas progress in crystallization yielded a significant reduce in the activation energy. This was because the relative crystallinity and temperature simultaneously increase during cold crystallization under non-isothermal conditions. Avrami analysis implied that CNC addition improved the crystallization rate of PLA possibly following athermal nucleation and two-dimensional discotic growth.

Graphical abstract

Similar content being viewed by others

References

R. A. Auras, L. T. Lim, S. E. Selke, H. Tsuji, (Eds.), Poly (lactic acid): synthesis, structures, properties, processing, and applications, (2010) John Wiley & Sons.

Nofar M. Multiphase polylactide blends: toward a sustainable and green environment. Elsevier; 2021.

Saad GR, Elsawy MA, Aziz MSA. Nonisothermal crystallization behavior and molecular dynamics of poly (lactic acid) plasticized with jojoba oil. J Therm Anal Calorim. 2017;128(1):211–23.

Raquez M, Habibi Y, Murariu M, Dubois P. Polylactide (PLA)-based nanocomposites. Prog Polym Sci. 2013;38:1504–42.

Delpouve N, Saiter-Fourcin A, Coiai S, Cicogna F, Spiniello R, Oberhauser W, Passaglia E. Effects of organo-LDH dispersion on thermal stability, crystallinity and mechanical features of PLA. Polymer. 2020;208: 122952.

Sarul DS, Arslan D, Vatansever E, Kahraman Y, Durmus A, Salehiyan R, Nofar M. Preparation and characterization of PLA/PBAT/CNC blend nanocomposites. Colloid Polym Sci. 2021;299(6):987–98. https://doi.org/10.1007/s00396-021-04822-9.

Clarkson CM, El Awad SM, Azrak RC, Shuvo SN, Snyder J, Schueneman G, Ortalan V, Youngblood JP. Melt spinning of cellulose nanofibril/polylactic acid (CNF/PLA) composite fibers for high stiffness. ACS Appl Polym Mater. 2018;1(2):160–8. https://doi.org/10.1021/acsapm.8b00030.

Sessini V, Palenzuela M, Damian J, Mosquera ME. Bio-based polyether from limonene oxide catalytic ROP as green polymeric plasticizer for PLA. Polymer. 2020;210: 123003.

O’Mahony C, Gkartzou E, Haq EU, Koutsoumpis S, Silien C, Charitidis CA, Tofail SAM. Determination of thermal and thermomechanical properties of biodegradable PLA blends: for additive manufacturing process. J Therm Anal Calorim. 2020;142(2):715–22.

Arul Jeya Kumar A, Prakash M. Thermal properties of basalt/Cissus quadrangularis hybrid fiber reinforced polylactic acid biomedical composites. J Therm Anal Calorim. 2020;141(2):717–25.

Müller AJ, Avila M, Saenz G, Salazar J. Crystallization of PLA-based Materials. InPoly (lactic acid) science and technology: processing, properties, additives and applications 2015 (Vol. 12). London, UK: The Royal Society of Chemistry.

Eom Y, Choi B, Park SI. A study on mechanical and thermal properties of PLA/PEO blends. J Polym Environ. 2019;27(2):256–62.

Yueagyen P, Lertworasirikul A. Study on crystallization of poly (lactic acid)/poly (propylene succinate) blends. Mater Today Proc. 2018;5(3):9609–14.

Clarkson CM, Azrak SM, Schueneman GT, Snyder JF, Youngblood JP. Crystallization kinetics and morphology of small concentrations of cellulose nanofibrils (CNFs) and cellulose nanocrystals (CNCs) melt-compounded into poly (lactic acid)(PLA) with plasticizer. Polymer. 2020;187:122101.

Abdolrsaouli MH, Babaei A, Kaschta J, Nazockdat H. Polylactide/organoclay nanocomposites: The effect of organoclay types on the structure development and the kinetic of cold crystallization. J Vinyl Addit Technol. 2019;25:48–58.

Xia X, Shi X, Liu W, Zhao H, Li H, Zhang Y. Effect of flax fiber content on polylactic acid (PLA) crystallization in PLA/flax fiber composites. Iran Polym J. 2017;26(9):693–702.

Jandas PJ, Mohanty S, Nayak SK. Cold crystallization kinetics of biodegradable polymer blend; controlled by reactive interactable and nano nucleating agent. Adv Composit Hybrid Mater. 2018;1(3):624–34.

Li H, Lu X, Yang H, Hu J. Non-isothermal crystallization of P (3HB-co-4HB)/PLA blends. J Therm Anal Calorim. 2015;122(2):817–29.

Hesami M, Jalali-Arani A. Cold crystallization behavior of poly (lactic acid) in its blend with acrylic rubber; the effect of acrylic rubber content. Polym Int. 2017;66(11):1564–71.

Yang JN, Nie SB, Qiao YH, Liu Y, Li ZY, Cheng GJ. Crystallization and rheological properties of the eco-friendly composites based on poly (lactic acid) and precipitated barium sulfate. J Polym Environ. 2019;27(12):2739–55.

Li Y, Han C, Yu Y, Xiao L, Shao Y. Crystallization behaviors of poly (lactic acid) composites fabricated using functionalized eggshell powder and poly (ethylene glycol). Thermochim Acta. 2018;663:67–76.

Díaz-Díaz AM, López-Beceiro J, Li Y, Cheng Y, Artiaga R. Crystallization kinetics of a commercial poly (lactic acid) based on characteristic crystallization time and optimal crystallization temperature. J Therm Anal Calorimet. 2021;145(6):3125–32.

Herc AS, Bojda J, Nowacka M, Lewinski P, Maniukiewicz W, Piorkowska E, Kowalewska A. Crystallization, structure and properties of polylactide/ladder poly (silsesquioxane) blends. Polymer. 2020;201: 122563.

Nofar M, Tabatabaei A, Park CB. Effects of nano-/micro-sized additives on the crystallization behaviors of PLA and PLA/CO2 mixtures. Polymer. 2013;54(9):2382–91.

Kelnar I, Kratochvil J, Kapralkova L. Crystallization and thermal properties of melt-drawn PCL/PLA microfibrillar composites. J Therm Anal Calorim. 2016;124(2):799–805.

Zhang C, Lan Q, Zhai T, Nie S, Luo J, Yan W. Melt crystallization behavior and crystalline morphology of polylactide/poly (ε-caprolactone) blends compatibilized by lactide-caprolactone copolymer. Polymers. 2018;10(11):1181.

Liao R, Yang B, Wei Y, Zhou C. Isothermal cold crystallization kinetics of polylactide/nucleating agents. J Appl Polym Sci. 2007;104(1):310–7. https://doi.org/10.1002/app.25733.

Guo T, Wang B. Isothermal cold crystallization and melting behaviors of poly(lactic acid)/epoxy vinyl polyhedral oligomeric silsesquioxanes nanocomposites. Polym-Plasti Technol Eng. 2014;53(9):917–26. https://doi.org/10.1080/03602559.2014.886061.

Marathe YN, Ramesh C, Badiger MV. Isothermal cold crystallization kinetics of borassus powder/poly (lactic acid) biocomposites. Polym Crystalliz. 2020;3(1): e10097.

Fernandez MJ, Fernandez MD. Effect of organic modifier and clay content on non-isothermal cold crystallization and melting behavior of polylactide/organovermiculite nanocomposites. Polymers. 2020;12(2):364.

Mendoza G, Pena-Juarez MG, Gonzalez-Calderon JA, Perez E. Use of chemically modified titanium dioxide particles to mediate the non-isothermal cold crystallization of poly (latic acid). J Mex Chem Soc. 2020;64(2):117–36.

Vatansever E, Arslan D, Nofar M. Polylactide cellulose-based nanocomposites. Int J Biol Macromol. 2019;137:912–38.

George J, Sabapathi SN. Cellulose nanocrystals: synthesis, functional properties, and applications. Nanotechnol Sci Appl. 2015;8:45.

Sturcova A, Davies GR, Eichhorn SJ. Elastic modulus and stress-transfer properties of tunicate cellulose whiskers. Biomacromol. 2005;6(2):1055–61.

Sojoudiasli H, Heuzey MC, Carreau PJ. Mechanical and morphological properties of cellulose nanocrystal-polypropylene composites. Polym Compos. 2018;39(10):3605–17.

Khoshkava V, Ghasemi H, Kamal MR. Effect of cellulose nanocrystals (CNC) on isothermal crystallization kinetics of polypropylene. Thermochim Acta. 2015;608:30–9.

Sapkota J, Natterodt JC, Shirole A, Foster EJ, Weder C. Fabrication and properties of polyethylene/cellulose nanocrystal composites. Macromol Mater Eng. 2017;302(1):1600300.

Heidarbeigi J, Afshari H, Borghei AM. Study of physical and mechanical properties of PE/CNC nanocomposite for food packaging applications. J Thermoplast Compos Mater. 2021;34(3):396–408.

Fortunati E, Luzi F, Janke A, Häußler L, Pionteck J, Kenny JM, Torre L. Reinforcement effect of cellulose nanocrystals in thermoplastic polyurethane matrices characterized by different soft/hard segment ratio. Polym Eng Sci. 2017;57(6):521–30.

Bagheriasl D, Carreau PJ, Riedl B, Dubois C. Enhanced properties of polylactide by incorporating cellulose nanocrystals. Polym Compos. 2018;39(8):2685–94.

Bagheriasl D, Carreau PJ, Riedl B, Dubois C, Hamad WY. Shear rheology of polylactide (PLA)–cellulose nanocrystal (CNC) nanocomposites. Cellulose. 2016;23(3):1885–97.

Bagheriasl D, Safdari F, Carreau PJ, Dubois C, Riedl B. Development of cellulose nanocrystal-reinforced polylactide: a comparative study on different preparation methods. Polym Compos. 2019;40(S1):E342–434.

Mohammadi M, Bruel C, Heuzey MC, Carreau PJ. CNC dispersion in PLA and PBAT using two solvents: morphological and rheological properties. Cellulose. 2020;27(17):9877–92.

Vatansever E, Arslan D, Sarul DS, Kahraman Y, Nofar M. Effects of molecular weight and crystallizability of polylactide on the cellulose nanocrystal dispersion quality in their nanocomposites. Int J Biol Macromol. 2020;154:276–90.

Mohammadi M, Heuzey MC, Carreau PJ, Taguet A. Morphological and rheological properties of PLA, PBAT, and PLA/PBAT blend nanocomposites containing CNCs. Nanomaterials. 2021;11(4):857.

Mohammadi M, Heuzey MC, Carreau PJ, Taguet A. Interfacial localization of CNCs in PLA/PBAT blends and its effect on rheological, thermal, and mechanical properties. Polymer. 2021;233:124229. https://doi.org/10.1016/j.polymer.2021.124229.

Arslan D, Vatansever E, Sarul DS, Kahraman Y, Gunes G, Durmus A, Nofar M. Effect of preparation method on the properties of polylactide/cellulose nanocrystal nanocomposites. Polym Compos. 2020;41(10):4170–80.

Sarul D, Arslan D, Vatansever E, Kahraman Y, Durmus A, Salehiyan R, Nofar M. Effect of mixing strategy on the structure-properties of the PLA/PBAT blends incorporated with CNC. J Renew Mater. 2021;10(1):149–64.

Arslan D, Vatansever E, Nofar M. Nanocellulose polylactide-based composite films for packaging applications. Bio-based Pack Mater Environ Econ Aspects. 2021;24:165–91.

Vatansever E, Arslan D, Sarul DS, Kahraman Y, Gunes G, Durmus A, Nofar M. Development of CNC-reinforced PBAT nanocomposites with reduced percolation threshold: a comparative study on the preparation method. J Mater Sci. 2020;55(32):15523–37.

Fortunati E, Armentano I, Zhou Q, Puglia D, Terenzi A, Berglund LA, Kenny JM. Microstructure and nonisothermal cold crystallization of PLA composites based on silver nanoparticles and nanocrystalline cellulose. Polym Degrad Stab. 2012;97(10):2027–36.

Zhang C, Salick MR, Cordie TM, Ellingham T, Dan Y, Turng LS. Incorporation of poly (ethylene glycol) grafted cellulose nanocrystals in poly (lactic acid) electrospun nanocomposite fibers as potential scaffolds for bone tissue engineering. Mater Sci Eng C. 2015;49:463–71.

Liu D, Yuan X, Bhattacharyya D. The effects of cellulose nanowhiskers on electrospun poly (lactic acid) nanofibers. J Mater Sci. 2012;47(7):3159–65.

Özdemir B, Nofar M. Effect of solvent type on the dispersion quality of spray-and freeze-dried CNCs in PLA through rheological analysis. Carbohydr Polym. 2021;268:118243. https://doi.org/10.1016/j.carbpol.2021.118243.

Fischer E, Sterzel HJ, Wegner G. Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reactions. Kolloid Z Z Polym. 1973;251(11):980–90.

Ayrilmis N, Yurttaş E, Durmus A, Özdemir F, Nagarajan R, Kalimuthu M, Kuzman MK. Properties of biocomposite films from PLA and thermally treated wood modified with silver nanoparticles using leaf extracts of oriental sweetgum. J Polym Environ. 2021;29(8):2409–20. https://doi.org/10.1007/s10924-021-02065-x.

Kwon M, Lee SC, Jeong YG. Influences of physical aging on enthalpy relaxation behavior, gas permeability, and dynamic mechanical property of polylactide films with various d-isomer contents. Macromol Res. 2010;18(4):346–51. https://doi.org/10.1007/s13233-010-0410-7.

Müller P, Imre B, Bere J, Moczo J, Pukanszky B. Physical ageing and molecular mobility in PLA blends and composites. J Therm Anal Calorim. 2015;122:1423–33.

Naeem Iqbal HM, Sungkapreecha C, Androsch R. Enthalpy relaxation of the glass of poly (l-lactic acid) of different d-isomer content and its effect on mechanical properties. Polymer Bull. 2017;74(7):2565–73. https://doi.org/10.1007/s00289-016-1854-5.

M.A. Sohel, A. Mondal, A. Sengupta, Effect of physical aging on glass transition and enthalpy relaxation in PLA Polymer filament. In: Proceeding in International Conference RAMSB-18, Mangalore (2018) 191–194.

Ozawa T. Kinetics of non-isothermal crystallization. Polymer. 1971;12:150.

Jiang Y, Han S, Zhang S, Li J, Huang G, Bi Y, Chai Q. Improved properties by hydrogen bonding interaction of poly (lactic acid)/palygorskite nanocomposites for agricultural products packaging. Polym Compos. 2014;35(3):468–76.

Kissinger HE. Variation of peak temperature with heating rate in differential thermal analysis. J Res Nat Bur Stand. 1956;57:217.

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404:163–76.

Augis JA, Bennett JE. Calculation of the Avrami parameters for heterogeneous solid state reactions using a modification of the Kissinger method. J Thermal Anal. 1978;13:283.

Takhor RL Advances in nucleation and crystallization of glasses; J Am Ceram Soc, (1971) 166–172.

Ozawa TA. New method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38:1881–6.

da Cruz É, Faria ML, Dias LM, Ferreira MI, Tavares B. Crystallization behavior of zinc oxide/poly(lactic acid) nanocomposites. J Therm Anal Calorimetry. 2020;146(4):1483–90. https://doi.org/10.1007/s10973-020-10166-3.

Oburoğlu N, Ercan N, Durmus A, Kaşgöz A. effects of halloysite nanotube on the mechanical properties and nonisothermal crystallization kinetics of poly(butylene terephthalate) (PBT). J Macromol Sci Part B. 2012;51(5):860–79. https://doi.org/10.1080/00222348.2011.610231.

Oburoğlu N, Ercan N, Durmus A, Kaşgöz A. Effects of filler type on the nonisothermal crystallization kinetics of poly (butylene terephthalate)(PBT) composites. J Appl Polym Sci. 2012;123(1):77–91.

Şanlı S, Durmus A, Ercan N. Effect of nucleating agent on the nonisothermal crystallization kinetics of glass fiber-and mineral-filled polyamide-6 composites. J Appl Polym Sci. 2012;125(S1):E268–81.

Avrami M. Kinetics of phase change, I general theory. J Chem Phys. 1939;7:1103.

Shi N, Dou Q. Non-isothermal cold crystallization kinetics of poly (lactic acid)/poly (butylene adipate-co-terephthalate)/treated calcium carbonate composites. J Therm Anal Calorim. 2015;119(1):635–42.

Xiao H, Yang L, Ren X, Jiang T, Yeh JT. Kinetics and crystal structure of poly (lactic acid) crystallized nonisothermally: effect of plasticizer and nucleating agent. Polym Compos. 2010;31(12):2057–68.

Liu T, Mo Z, Zhang H. Nonisothermal crystallization behavior of a novel poly (aryl ether ketone): PEDEKmK. J Appl Polym Sci. 1998;67(5):815–21.

Deshmukh GS, Peshwe DR, Pathak SU, Ekhe JD. Nonisothermal crystallization kinetics and melting behavior of poly (butylene terephthalate) and calcium carbonate nanocomposites. Thermochim Acta. 2015;606:66–76.

Zeng Y, Liu Y, Wang L, Huang H, Zhang X, Liu Y, Li Y. Effect of silver nanoparticles on the microstructure, non-isothermal crystallization behavior and antibacterial activity of polyoxymethylene. Polymers. 2020;12(2):424.

Liu Y, Guo W, Su Z, Li B, Wu C. Nonisothermal crystallization of recycled poly (ethylene terephthalate)/poly (ethylene octene) blends. J Macromol Sci. 2009;48(2):414–29.

Durmus A, Yalçınyuva T. Effects of additives on non-isothermal crystallization kinetics and morphology of isotactic polypropylene. J Polym Res. 2009;16(5):489–98.

Hu D, Chen J, Zhao L, Liu T. Melting and non-isothermal crystallization behaviors of polypropylene and polypropylene/montmorillonite nanocomposites under pressurized carbon dioxide. Thermochim Acta. 2015;617:65–75.

Karami S, Ahmadi Z, Nazockdast H, Rabolt JF, Noda I, Chase BD. The effect of well-dispersed nanoclay on isothermal and non-isothermal crystallization kinetics of PHB/LDPE blends. Mater Res Express. 2018;5(1): 015316.

dos Santos Silva ID, Schäfer H, Jaques NG, Siqueira DD, Ries A, de Souza Morais DD, Haag K, Koschek K, Carvalho LH, Ramos Wellen RM. An investigation of PLA/Babassu cold crystallization kinetics. J Therm Anal Calorimetry. 2020;141(4):1389–97.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alanalp, M.B., Ozdemir, B., Nofar, M. et al. Isothermal and non-isothermal cold crystallization kinetics of polylactide/cellulose nanocrystal (PLA/CNC) nanocomposites. J Therm Anal Calorim 147, 14211–14227 (2022). https://doi.org/10.1007/s10973-022-11598-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11598-9