Abstract

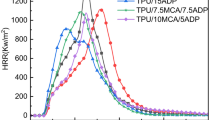

Rational design morphology of flame retardant is crucial to achieving a balance between satisfactory flame retardancy and superior mechanical properties. However, there are few studies focused on the morphology of flame retardants, and how to achieve the aim of satisfactory flame retardancy yet low mechanical properties loss is still a challenge. Herein, aluminum diethylphosphinate (ADP) with different morphologies were obtained through hydrothermal synthesis method via adjusting the releasing rate of Al3+, molar ratio (OH−: Al3+), and changing the type of acid. The morphology of ADP was successfully regulated from random (ADP-1), rod-like (ADP-2) to flower-like (ADP-3). The formation mechanism of different morphology was discussed in detail. The TG results indicated that all ADP have high thermal stability. Therefore, ADP as flame retardant was used for modification of TPU. Compared to neat TPU, TPU/ADP composites present lower initial decomposition temperature and higher char residual. With addition of 30% ADP-2 the LOI value increased from 22.5 to 28.0%, achieved the UL-94 V-2 rating, respectively. THR was 25.6% lower than that of virgin TPU, exhibiting higher fire safety performance. Meanwhile the tensile strength of TPU composite with ADP-2 (10.8 ± 0.4) is higher than that of the composites with ADP-1 (8.7 ± 0.9), and ADP-3 (7.9 ± 0.5) at content up to 30%. This work provides a promising strategy to tune the morphology of flame retardant and compromise the contradiction of poor mechanical properties with high fire safety of polymer composite.

Similar content being viewed by others

Data availability

The date will be ability on request.

References

Zhao D, Wang J, Wang X-L, Wang Y-Z (2018) Highly thermostable and durably flame-retardant unsaturated polyester modified by a novel polymeric flame retardant containing schiff base and spirocyclic structures. Chem Eng J 344:419–430

Shi YQ, Fu T, Xu YJ, Li DF, Wang XL, Wang YZ (2018) Novel phosphorus-containing halogen-free ionic liquid toward Fire safety epoxy resin with well-balanced comprehensive performance. Chem Eng J 354:208–219

Luo T, Jiao C, Chen X, Jiang H (2021) Flame-retardant effect of modified molecular sieve by ionic liquid in tpu. J Therm Anal Calorim 147:4141–4150

Wang J, Hu Y, Cai W, Yuan B, Zhang Y, Guo W, Hu W, Song L (2018) Atherton–Todd reaction assisted synthesis of functionalized multicomponent mose2/cnts nanoarchitecture towards the Fire safety enhancement of polymer. Compos Part A Appl Sci Manuf 112:271–282

Sut A, Metzsch-Zilligen E, Großhauser M, Pfaendner R, Schartel B (2018) Rapid mass calorimeter as a high-throughput screening method for the development of flame-retarded tpu. Polym Degrad Stab 156:43–58

Li N, Ming J, Yuan R, Fan S, Liu L, Li F, Wang X, Yu J, Wu D (2019) Novel eco-friendly flame retardants based on nitrogen–silicone schiff base and application in cellulose. ACS Sustain Chem Eng 8:290–301

He JH, Fu T, Li SL, Li Z, Lu JH, Lin YX, Liu C, Guo DM, Li WD, Wang YZ (2023) Intumescent closed-cell porous molecular engineering towards high flame retardancy and ultra-low smoke release epoxy resin. Compos Part A Appl Sci Manuf 172:107620

Meng D, Gu W, Zhu G, Sun J, Wang H, Nie F, Gu X, Bi P, Zhang S (2023) Interfacial architecting of long-acting hyperbranched flame retardant with high efficiency towards smoke-suppressed flexible polyurethane foam. Compos Part B: Eng 262:110816

Wang B, Wang X, Liu Y, Zhang Q, Yang G, Zhang D, Guo H (2023) Phytic acid-fe chelate cold-pressed self-forming high-strength polyurethane/marigold straw composite with flame retardance and smoke suppression. Polym Degrad Stab 208:110269

Liu J, Qi P, Chen F, Li X, Zhang J, Qian L, Gu X, Sun J, Zhang S (2023) Improving the hygroscopicity and flame retardancy of polyamide 6 fabrics by surface coating with β-FeOOH and sulfamic acid. Chemosphere 335:139115

Jiang M, Liu BW, He FM, Zhang Q, Wang A, Guo DM, Zhao HB, Chen L, Wang YZ (2023) High-performance flame-retardant aliphatic polyamide via enhanced chain entanglement. Chem Eng J 455:140637

Jing XK, Wang XS, Guo DM, Zhang Y, Zhai FY, Wang XL, Chen L, Wang YZ (2013) The high-temperature self-crosslinking contribution of azobenzene groups to the flame retardance and anti-dripping of copolyesters. J Mater Chem A 1:9264–9272

Nguyen-Ha TM, Nguyen TB, Nguyen TA, Pham LH, Nguyen DH, Nguyen DM, Hoang D, Oh E, Suhr J (2023) Novel high-performance sustainable polyurethane nanocomposite foams: Fire resistance, thermal stability, thermal conductivity, and mechanical properties. Chem Eng J 474:145585

Lu SY, Hamerton I (2002) Recent developments in the chemistry of halogen-free flame retardant polymers. Prog Polym Sci 27:1661–1712

Chen S, Li X, Li Y, Sun J (2015) Intumescent flame-retardant and self-healing superhydrophobic coatings on cotton fabric. ACS Nano 9:4070–4076

Levchik SV, Weil ED (2005) Overview of recent developments in the flame retardancy of polycarbonates. Polym Int 54:981–998

Zhan Z, Xu M, Li B (2015) Synergistic effects of sepiolite on the flame retardant properties and thermal degradation behaviors of polyamide 66/aluminum diethylphosphinate composites. Polym Degrad Stab 117:66–74

Marquis DM, Batiot B, Guillaume E, Rogaume T (2016) Influence of reaction mechanism accuracy on the chemical reactivity prediction of complex charring material in Fire condition. J Anal Appl Pyrolysis 118:231–248

Wang S, Lim QF, Toh JP, Tan MY, Zhu Q, Thitsartarn W, He C, Liu S, Kong J (2023) A versatile, highly effective intumescent flame-retardant synergist for polypropylene and polyamide 6 composites. Compos Commun 42:101699

Seefeldt H, Duemichen E, Braun U (2013) Flame retardancy of glass fiber reinforced high temperature polyamide by use of aluminum diethylphosphinate: thermal and thermo-oxidative effects. Polym Int 62:1608–1616

Ramani A, Dahoe AE (2014) On flame retardancy in polycaprolactam composites by aluminium diethylphosphinate and melamine polyphosphate in conjunction with organically modified montmorillonite nanoclay. Polym Degrad Stab 105:1–11

Bakirtzis D, Ramani A, Zhang J, Delichatsios MA (2014) Simplified structure of the condensed phase of Fire retarded PA6 nanocomposites in tga as related flammability. Fire Saf J 69:69–75

Gallo E, Braun U, Schartel B, Russo P, Acierno D (2009) Halogen-free flame retarded poly(butylene terephthalate) (pbt) using metal oxides/PBT nanocomposites in combination with aluminium phosphinate. Polym Degrad Stab 94:1245–1253

Isitman NA, Dogan M, Bayramli E, Kaynak C (2012) The role of nanoparticle geometry in flame retardancy of polylactide nanocomposites containing aluminium phosphinate. Polym Degrad Stab 97:1285–1296

Gallo E, Schartel B, Braun U, Russo P, Acierno D (2011) Fire retardant synergisms between nanometric Fe2O3 and aluminum phosphinate in poly(butylene terephthalate). Polym Adv Technol 22:2382–2391

Tang G, Wang X, Zhang R, Yang W, Hu Y, Song L, Gong X (2013) Facile synthesis of lanthanum hypophosphite and its application in glass-fiber reinforced polyamide 6 as a novel flame retardant. Compos Part A Appl Sci Manuf 54:1–9

Huang YW, Song SQ, Yang Y, Cao K, Yang JX, Chang GJ (2015) Decomposable double-walled hybrid nanorods: formation mechanism and their effect on flame retardancy of epoxy resin composites. J Mater Chem A 3:15935–15943

Xiao Y, Mu X, Wang B, Hu W, Wang J, Zhou F, Ma C, Hu Y, Song L (2021) A novel phosphorous-containing polymeric compatibilizer: effective reinforcement and flame retardancy in glass fiber reinforced polyamide 6 composites. Compos Part B: Eng 205:108536

Panda JN, Bijwe J, Pandey RK (2020) Variation in size of graphite particles and its cascading effect on the performance properties of paek composites. Compos Part B: Eng 182:107641

Yuan B, Bao C, Qian X, Jiang S, Wen P, Xing W, Song L, Liew KM, Hu Y (2014) Synergetic dispersion effect of graphene nanohybrid on the thermal stability and mechanical properties of ethylene vinyl acetate copolymer nanocomposite. Ind Eng Chem Res 53:1143–1149

Liu L, Wang W, Hu Y (2015) Layered double hydroxide-decorated flexible polyurethane foam: significantly improved toxic effluent elimination. RSC Adv 5:97458–97466

Chen W, Qu B (2003) Structural characteristics and thermal properties of pe-g-ma/mgal-ldh exfoliation nanocomposites synthesized by solution intercalation. Chem Mater 15:3208–3213

Wang X, Pang H, Chen W, Lin Y, Zong L, Ning G (2014) Controllable fabrication of zinc borate hierarchical nanostructure on brucite surface for enhanced mechanical properties and flame retardant behaviors. ACS Appl Mater Interfaces 6:7223–7235

Yin W, Wang Y, Ji Q, Yao J, Hou Y, Wang L, Zhong W (2014) Synthesis and formation mechanism of micro/nano flower-like MgCO3·5H2O. Int J of Min Met Mater 21:304–310

Peng LM, Li XK, Li H, Wang JH, Gong M (2006) Synthesis and microstructural characterization of aluminum borate whiskers. Ceram Int 32:365–368

Yang L, Han XY, Tang XJ, Han CX, Zhou YX, Zhang BG (2011) A novel photo-initiated approach for preparing aluminum diethylphosphinate under atmospheric pressure. Chin Chem Lett 22:385–388

Kang J, Hu C, Dichiara A, Guan L, Yun H, Gu J (2023) Facile preparation of cellulose nanocrystals/ZnO hybrids using acidified ZnCl(2) as cellulose hydrolytic media and ZnO precursor. Int J Biol Macromol 227:863–871

Scheck J, Berg JK, Drechsler M, Kempter A, Van Driessche AES, Cölfen H, Gebauer D, Kellermeier M (2022) New insights into the nucleation of magnesium hydroxide and the influence of poly(acrylic acid) during the early stages of mg(OH)2 crystallisation. CrystEngComm 24:7718–7726

Gong H, Ilavsky J, Kuzmenko I, Chen S, Yan H, Cooper CB, Chen G, Chen Y, Chiong JA, Jiang Y, Lai J-C, Zheng Y, Stone KH, Huelsenbeck L, Giri G, Tok JBH, Bao Z (2022) Formation mechanism of flower-like polyacrylonitrile particles. JACS 144:17576–17587

Kofina AN, Lioliou MG, Paraskeva CA, Klepetsanis PG, Østvold T, Koutsoukos PG (2009) Controlled precipitation of sparingly soluble phosphate salts using enzymes. Ii. Precipitation of struvite. Cryst Growth Des 9:4642–4652

Hsu JP, Nacu A (2005) Preparation of submicron-sized mg(OH)2 particles through precipitation. Colloids Surf Phy Engg Asp 262:220–231

Jeevanandam P, Mulukutla RS, Yang Z, Kwen H, Klabunde KJ (2007) Nanocrystals to nanorods: a precursor approach for the synthesis of magnesium hydroxide nanorods from magnesium oxychloride nanorods starting from nanocrystalline magnesium oxide. Chem Mater 19:5395–5403

Yu XL, Cao CB (2008) Photoresponse and field-emission properties of bismuth sulfide nanoflowers. Cryst Growth Des 8:3951–3955

Kukovec BM, Malik M, Kodrin I, Aakeröy CB, Đaković M (2016) Directed assembly of acac-based complexes by deliberately fine-tuning electrostatic molecular-recognition events. Cryst Growth Des 16:7308–7317

Wang F, Guo Y, Wang H, Yang L, Wang K, Ma X, Yao W, Zhang H (2011) Facile preparation of hydroxyapatite with a three dimensional architecture and potential application in water treatment. CrystEngComm 13:5634–5637

Peng WQ, Qu S, Cong G, Wang Z (2006) Synthesis and structures of morphology-controlled zno nano- and microcrystals. Cryst Growth Des 6:1518–1522

Jung SH, Oh E, Lim H, Shim DS, Cho S, Lee KH, Jeong SH (2009) Shape-selective fabrication of zinc phosphate hexagonal bipyramids via a disodium phosphate-assisted sonochemical route. Cryst Growth Des 9:3544–3547

Boyle DS, Govender K, O’Brien P (2002) Novel low temperature solution deposition of perpendicularly orientated rods of zno: substrate effects and evidence of the importance of counter-ions in the control of crystallite growth. Chem Commun 80–81

Luo YK, Song F, Wang XL, Wang YZ (2017) Pure copper phosphate nanostructures with controlled growth: a versatile support for enzyme immobilization. CrystEngComm 19:2996–3002

Zheng T, Wang W, Liu Y (2021) A novel phosphorus-nitrogen flame retardant for improving the flame retardancy of polyamide 6: Preparation, properties, and flame retardancy mechanism. Polym Adv Technol 32:2508–2516

Park SJ, Seo MK, Shim HB (2003) Effect of fiber shapes on physical characteristics of non-circular carbon fibers-reinforced composites. Mater Sci Eng A 352:34–39

Finnigan B, Jack K, Campbell K, Martin D, Halley P, Truss R, Casey P, Cookson D, King S (2005) Segmented polyurethane nanocomposites: Impact of controlled particle size nanofillers on the morphological response to uniaxial deformation. Macromolecules 38:7386–7396

Pinto UA, Visconte LLY, Nunes RC (2001) Mechanical properties of thermoplastic polyurethane elastomers with mica and aluminum trihydrate. Eur Polym J 37:1935–1937

Quan H, Zhang B-Q, Zhao Q, Yuen RK, Li RK (2009) Facile preparation and thermal degradation studies of graphite nanoplatelets (gnps) filled thermoplastic polyurethane (tpu) nanocomposites. Compos Part A Appl Sci Manuf 40:1506–1513

Wu C, Huang X, Wang G, Wu X, Yang K, Li S, Jiang P (2012) Hyperbranched-polymer functionalization of graphene sheets for enhanced mechanical and dielectric properties of polyurethane composites. J Mater Chem 22:7010–7019

Zhang R, Deng H, Valenca R, Jin J, Fu Q, Bilotti E, Peijs T (2013) Strain sensing behaviour of elastomeric composite films containing carbon nanotubes under cyclic loading. Compos Sci Technol 74:1–5

Liu L, Huang ZM, He CL, Han XJ (2006) Mechanical performance of laminated composites incorporated with nanofibrous membranes. Mater Sci Eng: A 435–436:309–317

Shamsi R, Mahyari M, Koosha M (2017) Synthesis of cnt-polyurethane nanocomposites using ester-based polyols with different molecular structure: mechanical, thermal, and electrical properties. J Appl Polym Sci 134:44567

Xiang J, Xie L, Meguid SA, Pang S, Yi J, Zhang Y, Liang R (2017) An atomic-level understanding of the strengthening mechanism of aluminum matrix composites reinforced by aligned carbon nanotubes. Comput Mater Sci 128:359–372

Chavarria F, Paul DR (2006) Morphology and properties of thermoplastic polyurethane nanocomposites: Effect of organoclay structure. Polymer 47:7760–7773

Samyn F, Bourbigot S (2012) Thermal decomposition of flame retarded formulations pa6/aluminum phosphinate/melamine polyphosphate/organomodified clay: interactions between the constituents? Polym Degrad Stab 97:2217–2230

Tang G, Wang X, Xing W, Zhang P, Wang B, Hong N, Yang W, Hu Y, Song L (2012) Thermal degradation and flame retardance of biobased polylactide composites based on aluminum hypophosphite. Ind Eng Chem Res 51:12009–12016

Braun U, Bahr H, Sturm H, Schartel B (2008) Flame retardancy mechanisms of metal phosphinates and metal phosphinates in combination with melamine cyanurate in glass-fiber reinforced poly(1,4-butylene terephthalate): the influence of metal cation. Polym Adv Technol 19:680–692

Li H, Chen L, Li Z, Wang W, Liu Y, Huang X, Liu Y (2023) Synergistic effect of SiO2 doped g-c3n4 and ammonium polyphosphate on flame retardancy of PA6 composites. J Polym Res 30:386

Chen X, Jiang Y, Jiao C (2014) Synergistic effects between hollow glass microsphere and ammonium polyphosphate on flame-retardant thermoplastic polyurethane. J Therm Anal Calorim 117:857–866

Xu SD, Gu S, Pu XL, Xiao YF, Lu JH, Wang YZ, Chen L (2022) Reaction-induced phase separation towards in situ network in epoxy resins for simultaneously improving thermal conductivity and Fire safety. Compos Part B: Eng 247:110326

Ye G, Huo S, Wang C, Shi Q, Yu L, Liu Z, Fang Z, Wang H (2021) A novel hyperbranched phosphorus-boron polymer for transparent, flame-retardant, smoke-suppressive, robust yet tough epoxy resins. ComposPart B: Eng 227:109395

Lyu W, Chen X, Li Y, Cao S, Han Y (2019) Thermal stability and heat release effect of flame retarded pa66 prepared by end-pieces capping technology. Compos Part B: Eng 167:34–43

Acknowledgements

This work was supported by the National Natural Science Foundation of China (grant no. 52273044, 52373092), the Opening Project of State Key Laboratory of Polymer Materials Engineering (Sichuan University)(grant no. sklpme2023-3-4), the Key Research Program of Zhejiang Province (grant no. 2023C01101, 2023C01210, 2022C01049, 2022C01205, 2022C01228), and the Natural Science Foundation of Zhejiang Province (grant no. LY20E030008).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, B., Ma, M., Wang, Y. et al. Morphology-manipulated aluminum diethylphosphinate and flame-retardant properties in thermoplastic polyurethane. J Polym Res 30, 455 (2023). https://doi.org/10.1007/s10965-023-03839-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03839-8