Abstract

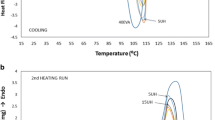

Ultra-high molecular weight polyethylene (UHMWPE) has extremely outstanding mechanical properties and wear resistance, but its melt flowability is too poor, resulting in poor processability. In this work, high-density polyethylene (HDPE) was melt-blended with UHMWPE to promote the flowability of UHMWPE melt. We investigated the effects of UHMWPE and HDPE contents on the rheological behavior, crystallization behavior, mechanical properties, and wear resistance of UHMWPE/HDPE blends. The results show that when the content ratio of UHMWPE and HDPE is 50:50, the UHMWPE/HDPE blend exhibits the best mechanical properties and wear resistance, as well as good processability. The tensile strength and elongation at break of 50UHMWPE/50HDPE are as high as 52.12 MPa and 700%, respectively, and the mass loss after erosion is only 0.04 g, which is far lower than the mass loss of pure HDPE (0.267g). Therefore, UHMWPE/HDPE blends with outstanding wear resistance and mechanical properties are expected to achieve large-scale industrial applications.

Similar content being viewed by others

Data availability

Data available on request from the corresponding authors.

References

Singh R, Singh S, Fraternali F (2016) Development of in-house blend wire based feed stock filaments of fused deposition modelling for wear-resistant materials and structures. Compos B Eng 98:244–249

Liu D, Xie H, Ma Z, Zhang W, Zhao H, Ren L (2022) Simultaneous enhancement of anti-friction and wear resistance performances via porous substrate and FeCoNiTiAl high entropy alloy coating of artificial joint materials. J Mater Sci Technol 19:2907–2915

Patil NA, Njuguna J, Kandasubramanian B (2020) UHMWPE for biomedical applications: Performance and functionalization. Eur Polym J 125:109529

Chen W, Biswas S, Roberts A, O’Shea J, Williams K (2017) Abrasion wear resistance of wall lining materials in bins and chutes during iron ore mining. Int J Miner Process 167:42–48

Sare IR, Mardel JI, Hill AJ (2001) Wear-resistant metallic and elastomeric materials in the mining and mineral processing industries. Wear 250:1–10

Wang X, Feng Y, Zhang L, Protsak I, Jamali R, Shu Y, Pal P, Wang Z, Yang J, Zhang D (2020) Fast-cured UV-LED polymer materials filled with high mineral contents as wear-resistant, antibacterial coatings. Chem Eng J 382:122927

Shalunov EP, Vladimirova YO (2021) Heat and wear-resistant blend material based on copper powder for heavy duty friction pairs. Mater Today Proc 38:1784–1788

Bodén I (2021) A new generation of wear resistant metal materials. Metal Powder Report 76:92–96

Ketan P, Chikkali SH, Sivaram S (2020) Ultrahigh molecular weight polyethylene: Catalysis, structure, properties, processing and applications. Prog Polym Sci 109:101290

Kurtz SM, Muratoglu OK, Evans M, Edidin A (1999) Advances in the processing, sterilization, and crosslinking of ultra-high molecular weight polyethylene for total joint arthroplasty. Biomaterials 20:1659–1688

Hofmann D, Kurek A, Thomann R, Schwabe J, Mark S, Enders M, Hees T, Mülhaupt R (2017) Tailored nanostructured HDPE wax/UHMWPE reactor blends as additives for melt-processable all-polyethylene blends and in Situ UHMWPE Fiber Reinforcement. Macromolecules 50:8129–8139

Sui Y, Li J, Qiu Z, Cui Y, Cong C, Meng X, Ye H, Zhou Q (2022) Effects of the sintering temperature on the superior cryogenic toughness of ultra-high molecular weight polyethylene (UHMWPE). Chem Eng J 444:136366

Wang Y, Fu J, Liu M, Fu Q, Zhang J (2019) Understanding the effect of chain entanglement state on melt crystallization of the polymer freeze-extracted from solution: The role of critical overlap concentration. Polymer 178:121588

Liu G, Li H (2003) Extrusion of ultrahigh molecular weight polyethylene under ultrasonic vibration field. J Appl Polym Sci 89:2628–2632

Liu CY, Ishigami A, Kurose T, Ito H (2021) Wear resistance of graphene reinforced ultra-high molecular weight polyethylene nanoblends prepared by octa-screw extrusion process. Compos B Eng 215:108810

Li Q, Dong P, Liu H, Zhang L, Zhang Q, Wang K (2021) Towards high-performance all-polyethylene materials by a two-step processing strategy using two-roll mill. Polymer 228:123956

Zhang L, Lu C, Dong P, Wang K, Zhang Q (2019) Realizing mechanically reinforced all-polyethylene material by dispersing UHMWPE via high-speed shear extrusion. Polymer 180:121711

Gong Y, Wang SH, Zhang ZY, Yang XL, Yang ZG, Yang HG (2021) Degradation of sunlight exposure on the high-density polyethylene (HDPE) pipes for transportation of natural gases. Polym Degrad Stab 194:109752

Yang H, Yilmaz G, Jiang J, Xie J, Langstraat T, Chu R, van Es M, Garg P, Turng LS (2022) Pelletizing ultra-high molecular weight polyethylene (UHMWPE) powders with a novel tapered die and addition of high density polyethylene (HDPE): Processing, morphology, and properties. Polymer 256:125171

Savini G, Oréfice RL (2017) Toughening high density polyethylene submitted to extreme ambient temperatures. J Polym Res 24:79

Suresha B, Sriraksha Hemanth R (2020) Mechanical Performance of HDPE/UHMWPE Hybrid Blends and Tribological Characterization using Taguchi Method. Mater Today Proc 24:1452–1461

Lucas A, Ambrósio JD, Otaguro H, Costa LC, Agnelli JAM (2011) Abrasive wear of HDPE/UHMWPE blends. Wear 270:576–583

Shen H, He L, Fan C, Xie B, Yang W, Yang M (2015) Improving the integration of HDPE/UHMWPE blends by high temperature melting and subsequent shear. Mater Lett 138:247–250

Sui Y, Li J, Cui Y, Qiu Z, Wei P, Cong C, Meng X, Zhou Q (2023) Eminent Differences in Cryogenic toughness of Ultra-high Molecular Weight Polyethylene (UHMWPE) with Different Entanglement Densities. J Appl Polym Sci 140:e53475

Wunderlich B, Cormier C (1967) Heat of Fusion of Polyethylene. J Polym Sci 2 Polym 5:987–988

Xie Y, Jiang J, Tufa KY, Yick S (2015) Wear resistance of materials used for slurry transport. Wear 332:104–1110

Ferry JD (1970) Viscoelastic properties of polymers. Wiley-Interscience, New York

Zuo J, Liu S, Zhao J (2015) Cocrystallization behavior of HDPE/UHMWPE blends prepared by two-step processing way. Polym Polym Compos 23:59–63

Dong P, Zhang Q, Wang K, Zhu BH, Su W, Li JF, Fu Q (2021) Pursuit of the correlation between yield strength and crystallinity in sintering-molded UHMWPE. Polymer 215:123352

Böhm H, Betz S, Ball A (1990) The wear resistance of polymers. Tribol Int 23:399–406

Acknowledgement

All authors would like to appreciate the financial support from the National Key Research and Development Program of China, Grant Number: 2022YFC2803702; China Merchant Offshore Technology Research Center, Grant/Award Number: CMRD-B038. In addition, the authors would like to appreciate the Shiyanjia Lab (www.shiyanjia.com) for their technical support on DSC testing.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

All the authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sui, Y., Qiu, Z., Liu, Y. et al. Ultra-high molecular weight polyethylene (UHMWPE)/high-density polyethylene (HDPE) blends with outstanding mechanical properties, wear resistance, and processability. J Polym Res 30, 222 (2023). https://doi.org/10.1007/s10965-023-03592-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03592-y