Abstract

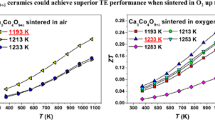

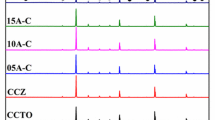

The Ca3Ti2O7 materials exhibit hybrid improper ferroelectricity due to the rotation and tilt coupling of TiO6 octahedron. However, the lower remnant polarization of Ca3Ti2O7 ceramics obtained by conventional solid-state method limits its practical application. Herein, the single-phase Ca3Ti2O7 ceramics with enhanced ferroelectricity were synthesized using an acetic acid sol–gel method and two-stage sintering. The sintering process does not significantly change the distortion amplitude of TiO6 octahedron in Ca3Ti2O7 ceramics but has a greater impact on the grain size and the concentration of oxygen vacancy. The synergistic effects of grain size and oxygen vacancy have been achieved in the Ca3Ti2O7 ceramics prepared by the optimal sintering process (1400 °C/12 h − 1550 °C/18 h), which leads to its enhanced hybrid ferroelectricity (Pr = 1.34 μC/cm2 and EC = 120 kV/cm). These findings demonstrate that the sol–gel method is an effective approach to obtain the Ca3Ti2O7 materials with enhanced hybrid improper ferroelectricity.

Similar content being viewed by others

References

Y. Zhao, J.P. Zhu, H.L. Wang, Z. Ma, L.H. Gao, Y.B. Liu, Y. Liu, Y.C. Shu, J.L. He, Ceram Int. 47, 5549–5558 (2020). https://doi.org/10.1016/j.ceramint.2020.10.139

M.M.S. Sanad, M.M. Rashad, E.A. Abdel-Aal, Int. J. Appl. Ceram. Technol. 11, 157–176 (2014). https://doi.org/10.1111/ijac.12237

W. Wang, Y. Jiang, P.J. Thomas, Sensors. 21, 1112 (2021). https://doi.org/10.3390/s21041112

G.H. Haertling, J Am Ceram Soc. 82, 797–818 (2010). https://doi.org/10.1111/j.1151-2916.1999.tb01840.x

M.M.S. Sanad, M.M. Rashad, E.A. Abdel-Aal, K. Powers, Mater. Chem. Phys. 162, 299–307 (2015). https://doi.org/10.1016/j.matchemphys.2015.05.071

S. Pattipaka, J.P. Goud, G.P. Bharti, K.C.J. Raju, A. Khare, D. Pamu, J. Mater. Sci: Mater Electron. 31, 2986–2996 (2020). https://doi.org/10.1007/s10854-019-02842-4

H. Li, C.R. Bowen, Y. Yang, Adv. Funct. Mater. 31, 2100905 (2021). https://doi.org/10.1002/adfm.202100905

Y.H. Tian, F. Xue, L. Tang, W. Li, L. Jing, S, Li. J Mater Sci: Mater Electron. 32, 18825–18836 (2021). https://doi.org/10.1007/s10854-021-06399-z

Q. Xu, W. Huang, R. Deng, H. Chen, H. Liu, J. Mater. Sci: Mater Electron. 32, 13539–13548 (2021). https://doi.org/10.1007/s10854-021-05930-6

A.E. Hannora, M.A. Abbas, M.M. El-Desoky, J. Mater. Sci: Mater Electron. 32, 3998–4007 (2021). https://doi.org/10.1007/s10854-020-05142-4

F.T. Huang, S.W. Cheong, Nat. Rev. Mater. 2, 17004 (2017). https://doi.org/10.1038/natrevmats.2017.4

F.T. Huang, F. Xue, B. Gao, L.H. Wang, X. Luo, W. Cai, X.Z. Lu, J.M. Rondinelli, L.Q. Chen, S.W. Cheong, Nat. Commun. 7, 11602 (2016). https://doi.org/10.1038/ncomms11602

S. Liu, H. Zhang, S. Ghose, M. Balasubramanian, Z.X. Liu, S.G. Wang, Y.S. Chen, B. Gao, J. Kim, S.W. Cheong, T.A. Tyson, Phys. Rev. B. 99, 224105 (2019). https://doi.org/10.1103/PhysRevB.99.224105

N.A. Benedek, C.J. Fennie, Phys. Rev. Lett. 106, 107204 (2011). https://doi.org/10.1103/physrevlett.106.107204

Y.S. Oh, X. Luo, F.T. Huang, Y.Z. Wang, S.W. Cheong, Nat. Mater. 14, 407–413 (2015). https://doi.org/10.1038/nmat4168

M.F. Liu, Y. Zhang, L.F. Lin, L. Lin, S.W. Yang, X. Li, Y. Wang, S.Z. Li, Z.B. Yan, X.Z. Wang, X.G. Li, S. Dong, J.M. Liu, Appl. Phys. Lett. 113, 022902 (2018). https://doi.org/10.1063/1.5037525

S.M. Lei, M.Q. Gu, D. Puggioni, G. Stone, J. Peng, J.J. Ge, Y. Wang, B.M. Wang, Y.K. Yuan, K. Wang, Z.Q. Mao, J.M. Rondinelli, V. Gopalan, Nano Lett. 18, 3088–3095 (2018). https://doi.org/10.1021/acs.nanolett.8b00633

Y.Z. Wang, F.T. Huang, X. Luo, B. Gao, S.W. Cheong, Adv. Mater. 29, 1601288 (2016). https://doi.org/10.1002/adma.201601288

S. Yoshida, K. Fujita, H. Akamatsu, O. Hernandez, A.S. Gupta, F.G. Brown, H. Padmanabhan, A.S. Gibbs, T. Kuge, R. Tsuji, S. Murai, J.M. Rondinelli, V. Gopalan, K. Tanaka, Adv. Funct. Mater. 28, 1801856 (2018). https://doi.org/10.1002/adfm.201801856

X.Q. Liu, J.W. Wu, X.X. Shi, H.J. Zhao, H.Y. Zhou, R.H. Qiu, W.Q. Zhang, X.M. Chen, Appl. Phys. Lett. 106, 202903 (2015). https://doi.org/10.1063/1.4921624

G.J. Li, X.Q. Liu, J.J. Lu, H.Y. Zhu, X.M. Chen, J. Appl. Phys. 123, 014101 (2018). https://doi.org/10.1063/1.5001956

C. Huang, W. Wong-Ng, W.F. Liu, X.N. Zhang, Y. Jiang, P. Wu, B.Y. Tong, H. Zhao, S.Y. Wang, J. Alloys Compd. 770, 582–588 (2019). https://doi.org/10.1016/j.jallcom.2018.08.172

Z.Z. Hu, J.J. Lu, B.H. Chen, T.T. Gao, X.Q. Liu, W. Wen, X.M. Chen, J. Materiomics. 5, 618–625 (2019). https://doi.org/10.1016/j.jmat.2019.07.002

B.H. Zhang, Z.Z. Hu, B.H. Chen, X.Q. Liu, X.M. Chen, J. Appl. Phys. 128, 054102 (2020). https://doi.org/10.1063/5.0014208

X. Ji, C.B. Wang, W.K. Luo, G. Chen, S. Zhang, R. Tu, Q. Shen, J. Shi, L.M. Zhang, J. Sol-Gel Sci. Techn. 94, 205–212 (2020). https://doi.org/10.1007/s10971-019-05177-y

H.D. Wu, W. Cai, C. Zhou, Q.W. Zhang, R.L. Gao, G. Chen, X.L. Deng, Z.H. Wang, C.L. Fu, Mater. Lett. 278, 128447 (2020). https://doi.org/10.1016/j.matlet.2020.128447

Y. Cui, W. Gu, X.X. Kong, Z.D. Gao, S.Y. Yu, J. Mater. Sci-Mater. El. 30, 9194–9199 (2019). https://doi.org/10.1007/s10854-019-01248-6

P. Visuttipitukul, P. Sooksaen, N. Yongvanich, Ferroelectrics 457, 82–88 (2013). https://doi.org/10.1080/00150193.2013.848755

M.G. Garnica-Romo, A. Páez-Sánchez, L. García-González, I. Domínguez-López, L.L. Díaz-Flores, M. Villicaña-Mendez, J. Sol-Gel Sci. Techn. 74, 425–431 (2015). https://doi.org/10.1007/s10971-015-3617-4

X.X. Wu, S.Y. Wang, W.N. Wong, G.U. Qiang, Y. Jiang, C. Wang, S. Ma, W.F. Liu, J. Adv. Ceram. 9, 120–128 (2020). https://doi.org/10.1007/s40145-020-0425-2

R.H. Zhang, A.S. Gibbs, W.G. Zhang, P.S. Halasyamani, M.A. Hayward, Inorg. Chem. 56, 9988–9995 (2017). https://doi.org/10.1021/acs.inorgchem.7b01525

B.H. Chen, T.L. Sun, X.Q. Liu, X.L. Zhu, H. Tian, X.M. Chen, Appl. Phys. Lett. 116, 042903 (2020). https://doi.org/10.1063/1.5138672

C.Q. Zhu, X.H. Wang, Q.H. Zhao, Z.M. Cai, Z.Y. Cen, L.T. Li, J. Eur. Ceram. Soc. 39, 1142–1148 (2018). https://doi.org/10.1016/j.jeurceramsoc.2018.11.034

T. Kusama, T. Omori, T. Saito, S. Kise, T. Tanaka, Y. Araki, R. Kainuma, Nat. Commun. 8, 354 (2017). https://doi.org/10.1038/s41467-017-00383-0

Q.W. Zhang, W. Cai, Q.T. Li, R.L. Gao, G. Chen, X.L. Deng, Z.H. Wang, X.L. Cao, C.L. Fu, J. Alloys Compd. 794, 542–552 (2019). https://doi.org/10.1016/j.jallcom.2019.04.247

A.C. Tomkiewicz, M. Tamimi, A. Huq, S. McIntosh, J. Mater. Chem. A. 3, 21864–21874 (2015). https://doi.org/10.1039/c5ta04193g

Y.H. Ling, F. Wang, R.A. Budiman, T. Nakamura, K. Amezawa, Phys. Chem. Chem. Phys. 17, 7489–7497 (2015). https://doi.org/10.1039/c4cp05719h

F.Q. Wang, W. Cai, C.L. Fu, R.L. Gao, Z.H. Wang, G. Chen, X.L. Deng, J. Mater. Sci-Mater. El. 30, 2177–2185 (2018). https://doi.org/10.1007/s10854-018-0489-8

T. Fan, C. Ji, G. Chen, W. Cai, R.L. Gao, X.L. Deng, Z.H. Wang, C.L. Fu, Mater. Chem. Phys. 250, 123034 (2020). https://doi.org/10.1016/j.matchemphys.2020.123034

X.W. Wang, P.B. Jia, X.E. Wang, B.H. Zhang, L.Y. Sun, Q.B. Liu, J. Mater, Sci-Mater. El. 27, 12134–12140 (2016). https://doi.org/10.1007/s10854-016-5366-8

C.C. Wang, L.W. Zhang, Phys. Rev. B. 74, 024106 (2006). https://doi.org/10.1103/physrevb.74.024106

T.F. Zhang, X.G. Tang, Q.X. Liu, Y.P. Jiang, X.X. Huang, J. Am. Ceram. Soc. 98, 551–558 (2015). https://doi.org/10.1111/jace.13317

D.G. Chen, X.G. Tang, Q.X. Liu, Y.P. Jiang, C.B. Ma, R. Li, J. Appl. Phys. 113, 214110 (2013). https://doi.org/10.1063/1.4809541

M. Kratochvilova, F.T. Huang, M.T.F. Diaz, M. Klicpera, S.J. Day, S.P. Thompson, Y.S. Oh, B. Gao, S.W. Cheong, J.G. Park, J. Appl. Phys. 125, 244102 (2019). https://doi.org/10.1063/1.5089723

Y.L. Han, W.F. Liu, X.L. Xu, M.C. Guo, X.N. Zhang, P. Wu, J. Gao, G.H. Rao, S.Y. Wang, J. Am. Ceram. Soc. 99, 3616–3622 (2016). https://doi.org/10.1111/jace.14381

F.P.G. Fengler, M. Pešic´, S. Starschich, T. Schneller, C. Künneth, U. Böttger, H. Mulaosmanovic, T. Schenk, M.H. Park, R. Nigon, P. Muralt, T. Mikolajick, U. Schroede, Adv. Electron. Mater. 3, 1600505 (2017). https://doi.org/10.1002/aelm.201600505

Acknowledgements

This work was supported by the Program for Creative Research Groups in University of Chongqing, China (CXQT19031), the Innovation Program for Chongqing's Overseas Returnees, China (cx2019159), the Natural Science Foundation of Chongqing, China (CSTC2020jcyj-msxmX0030, CSTC2020jcyj-zdxmX0008), the National Training Program of Innovation and Entrepreneurship for Undergraduates (202011551001), the Chongqing KeHui Graduate Student Innovation and Entrepreneurship Competition (10111094, 10111043) and the Graduate Science and Technology Innovation Training Program Project of Chongqing University of Science and Technology (YKJCX2020220).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, H., Cai, W., Zhou, C. et al. Optimization of sintering process and enhanced hybrid improper ferroelectricity of Ca3Ti2O7 ceramics fabricated by an acetic acid sol–gel method. J Mater Sci: Mater Electron 32, 24328–24341 (2021). https://doi.org/10.1007/s10854-021-06902-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06902-6