Abstract

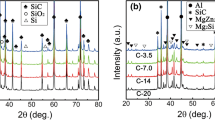

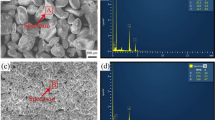

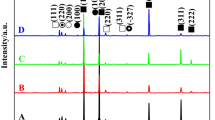

In this work, the TC4/AZ91 composites were fabricated through spark plasma sintering (SPS) followed by hard plate rolling (HPR) of a novel processing technology. The microstructure evolution and mechanical properties of the magnesium (Mg) matrix composites (MMCs) were investigated. The results illustrated that there were no other precipitates in TC4/AZ91 composites except for α-Ti and Mg17Al12 phases. The grains were refined significantly and TC4 particles occurred plastic deformation after a single pass via HPR, and the grain refinement of the TC4/AZ91 composites after HPR was attributed to TC4-induced particle-stimulated nucleation (PSN) mechanism and the pinning effect of fine Mg17Al12 phases. The deformable TC4 particles were beneficial to alleviate the stress concentration around them, resulting in dynamic recrystallization grain size around them being slightly smaller than relatively far away. Among them, the TC4/AZ91 composite with a thickness reduction of 70% by HPR exhibited favorable comprehensive mechanical properties: The yield strength (YS), ultimate tensile strength (UTS) and elongation (EL) were 206 Mpa, 349 Mpa and 7.9%, respectively. The superior mechanical properties were primarily ascribed to three aspects: (I) grain refinement, (II) the good interfacial bonding between Mg matrix and TC4 particles, and (III) the deformability of TC4 particles.

Similar content being viewed by others

Data and code availability

Not applicable.

References

Prasad SVS, Prasad SB, Verma K, Mishra RK, Kumar V, Singh S (2021) The role and significance of magnesium in modern day research-a review. J Magn Alloy 10(1):1–61

Song JF, She J, Chen DL, Pan FS (2020) Latest research advances on magnesium and magnesium alloys worldwide. J Magn Alloy 8:1–41

Dong YP, Tang JC, Wang DW, Wang N, He ZD, Li J, Zhao DP, Yan M (2020) Additive manufacturing of pure Ti with superior mechanical performance, low cost, and biocompatibility for potential replacement of Ti-6Al-4V. Mater Des 196:109142

Hu M, Wei S, Shi Q, Ji Z, Xu H, Wang Y (2020) Dynamic recrystallization behavior and mechanical properties of bimodal scale Al2O3 reinforced AZ31 composites by soild state synthesis. J Magn Alloy 8(3):841–848

Singh N, Belokar RM (2021) Tribological behavior of aluminum and magnesium-based hybrid metal matrix composites: a state-of-art review. Mater Today Proc 44:460–466

Wang XJ, Wang NZ, Wang LY, Hu XS, Wu K, Wang YQ, Huang YD (2014) Processing, microstructure and mechanical properties of micro-SiC particles reinforced magnesium matrix composites fabricated by stir casting assisted by ultrasonic treat. Mater Design 57:638–645

Xiao P, Gao YM, Xu FX, Yang SS, Li YF, Li B, Zhao SY (2019) Hot deformation behavior of in-situ nanosized TiB2 particulate reinforced AZ91 Mg matrix composite. J Alloy Compd 798:1–11

Zhang B, Yang CL, Li HX, Sun YX, Yan YZ, Zhao TH, Li XL, Liu F (2020) Achieving high strength-ductility combination and negligible yield asymmetry in extruded AlN/AZ91 composite rods. Mater Sci Eng A 773:138842

Wang BJ, Xu DK, Wang SD, Sheng LY, Zeng RC, Han EH (2019) Influence of solution treatment on the corrosion fatigue behavior of an as-forged Mg-Zn-Y-Zr alloy. Int J Fatigue 120:46–55

Wang X, Wang X, Hu X, Wu K (2020) Effects of hot extrusion on microstructure and mechanical properties of Mg matrix composite reinforced with deformable TC4 particles. J Magn Alloy 8(2):421–430

Zhu S, Luo T, Zhang T, Li Y, Yang Y (2017) Effects of Cu addition on the microstructure and mechanical properties of as-cast and heat-treated Mg-6Zn-4Al magnesium alloy. Mater Sci Eng A 689:203–211

Kim JI, Nguyen HN, You BS, Kim YM (2019) Effect of Y addition on removal of Fe impurity from magnesium alloys. Scripta Mater 162:355–360

Rashad M, Pan F, Asif M, She J, Ullah A (2015) Improved mechanical proprieties of “magnesium-based composites” with titanium-aluminum hybrids. J Magn Alloy 3:1–9

Yu H, Zhou H, Sun Y, Ren L, Wan Z, Hu L (2018) Microstructures and mechanical properties of ultrafine-grained Ti/AZ31 magnesium matrix composite prepared by powder metallurgy. Adv Powder Technol 29(12):3241–3249

Rashad M, Pan F, Tang A, Lu Y, Asif M, Hussain S, She J, Gou J, Mao J (2013) Effect of graphene nanoplatelets (GNPs) addition on strength and ductility of magnesium titanium alloys. J Magn Alloy 1(3):242–248

Huang G, Shen Y (2017) The effects of processing environments on the microstructure and mechanical properties of the Ti/5083Al composites produced by friction stir processing. J Manuf Process 30:361–373

Roy S, Kannan G, Suwas S, Surappa MK (2015) Effect of extrusion ratio on the microstructure, texture and mechanical properties of (Mg/AZ91)m-SiCp composite. Mater Sci Eng A 624:279–290

Dinaharan I, Zhang S, Chen G, Shi Q (2020) Titanium particulate reinforced AZ31 magnesium matrix composites with improved ductility prepared using friction stir processing. Mater Sci Eng A 772:138793

Wang HY, Yu ZP, Zhang L, Liu CG, Zha M, Wang C, Jiang QC (2015) Achieving high strength and high ductility in magnesium alloy using hard-plate rolling (HPR) process. Sci Rep 5:17100

Yu H, Sun Y, Wan Z, Zhou H, Hu L (2018) Nanocrystalline Ti/AZ61 magnesium matrix composite: evolution of microstructure and mechanical property during annealing treatment. J Alloy Compd 741:231–239

Wang XJ, Wu K, Zhang HF, Huang WX, Chang H, Gan WM, Zheng MY, Peng DL (2007) Effect of hot extrusion on the microstructure of a particulate reinforced magnesium matrix composite. Mater Sci Eng A 465:78–84

Xiang SL, Gupta M, Wang XJ, Wang LD, Hu XS, Wu K (2017) Enhanced overall strength and ductility of magnesium matrix composites by low content of graphene nanoplatelets. Compos A 100:183–193

Luo H, Li JH, Ye JL, Lu YF, Tan J, Song JF, Chen XH, Zheng KH, Pan FS (2022) Influence of Ti-6Al-4V particles on the interfacial microstructure and strength-ductility synergetic mechanism of AZ91 magnesium alloy. Mater Charact 191:112154

Yu Z, Tang A, Zhang L, Pan F (2014) Effect of microalloying with titanium on microstructure and mechanical properties of AZ91 magnesium alloy. Mater Sci Technol 30:1441–1446

Chua BW, Lu L, Lai MO (1999) Influence of SiC particles on mechanical properties of Mg based composite. Compos Struct 47:595–601

Deng KK, Wu K, Wu YW, Nie KB, Zheng MY (2010) Effect of submicron size SiC particulates on microstructure and mechanical properties of AZ91 magnesium matrix composites. J Alloy Compd 504:542–547

Xiao P, Gao YM, Yang CC, Liu ZW, Li YF, Xu FX (2018) Microstructure, mechanical properties and strengthening mechanisms of Mg matrix composites reinforced with in situ nanosized TiB2 particles. Mater Sci Eng A 710:251–259

Robson JD, Henry DT, Davis B (2009) A new class of metrics for the macroscopic crystallographic space of grain boundaries. Acta Mater 57(9):2739–2747

Liu L, Zhou X, Yu S, Zhang J, Lu X, Shu X, Su Z (2020) Effects of heat treatment on mechanical properties of an extruded Mg-4.3Gd-3.2Y-1.2Zn-0.5Zr alloy and establishment of its Hall-Petch relation. J Magn Alloy 10(2):501–512

Chen LY, Xu JQ, Choi H, Pozuelo M, Ma X, Bhowmick S, Yang JM, Mathaudhu S, Li XC (2015) Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 528:539–543

Chelliah NM, Singh H, Raj R, Surappa MK (2017) Processing, microstructural evolution and strength properties of in-situ magnesium matrix composites containing nano-sized polymer derived SiCNO particles. Mater Sci Eng A 685:429–438

Rashad M, Pan F, Asif M (2016) Exploring mechanical behavior of Mg–6Zn alloy reinforced with graphene nanoplatelets. Mater Sci Eng A 649:263–269

Vahedi F, Zarei-Hanzaki A, Salandari-Rabori A, Abedi HR, Razaghian A, Minarik P (2020) Microstructural evolution and mechanical properties of thermomechanically processed AZ31 magnesium alloy reinforced by micrographite and nano-graphene particles. J Alloys Compd 815:152231

Ye JL, Li JB, Luo H, Tan J, Chen XH, Feng B, Zheng KH, Pan FS (2022) Effect of micron-Ti particles on microstructure and mechanical properties of Mg-3Al-1Zn based composites. Mater Sci Eng A 833:142526

Acknowledgements

All people who have contributed to this work have included in the author list. And, the financial funding supported by Northwest Institute For Non-ferrous Metal Research (YK2021-1/ZZML-2201).

Author information

Authors and Affiliations

Contributions

XC was involved in conceptualization, methodology, investigation, validation, resources, supervision and writing—reviewing and editing. BW was responsible for methodology, investigation and validation. ML took part in methodology, project administration and funding acquisition. JL participated in investigation and validation.

Corresponding author

Ethics declarations

Conflicts of interest

There are no actual or potential conflicts of interest that have appeared to influence the work reported in this paper.

Ethical approval

Not applicable.

Supplementary information

This section mainly includes some unimportant information in the manuscript including the size of the raw powder and some chemical reagent components, with the aim of increasing its completeness.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cao, X., Wu, B., Liang, M. et al. Effect of hard plate rolling on microstructure and mechanical properties of Mg-9Al-1Zn-based composites reinforced with Ti-6Al-4V particles. J Mater Sci 58, 16474–16487 (2023). https://doi.org/10.1007/s10853-023-09044-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09044-8