Abstract

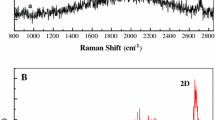

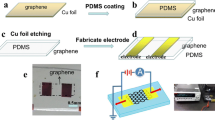

The inconsistent conductivity and surface roughness of commercially available chemical vapour deposition (CVD) monolayer graphene films have limited their widespread adoption in optoelectronic devices. This study presents a novel approach to address this issue by investigating the effect of post-thermal annealing on the sheet resistance (Rs) and surface properties of CVD monolayer graphene films on quartz substrates. The films undergo thermal annealing at temperatures ranging from 200 to \(600\,^{\circ }\hbox {C}\) in a nitrogen environment using a one-zone tube furnace. Remarkably, annealing the graphene films at \(400\,^{\circ }\hbox {C}\) leads to a remarkable reduction in Rs by 58.1% and surface roughness (Ra) by 33.3%. In-depth analysis using Raman spectroscopy reveals that the Rs reduction is attributed to increased charge density from doping effects, while the Ra reduction is attributed to thermal-induced mechanical biaxial tensile strain. Moreover, the Raman spectrum exhibits a remarkable 67.3% reduction in the quality–intensity ratio (\({I}_\textrm{D}\)/\({I}_\textrm{G}\)) of the graphene film annealed at \(400\,^{\circ }\hbox {C}\), confirming a defect-free state, and further validating the healing effect on the commercially procured graphene films. These findings offer great potential for enhancing the performance and reliability of commercially available CVD monolayer graphene films in optoelectronic devices. By introducing a practical solution to improve conductivity and surface roughness, post-thermal annealing at an optimal temperature of \(400\,^{\circ }\hbox {C}\) presents a promising and innovative approach to unlock the full potential of CVD monolayer graphene films in various technological applications.

Similar content being viewed by others

Data and code availability

Not applicable.

References

Allen MJ, Tung VC, Kaner RB (2009) Honeycomb carbon: a review of graphene. Chem Rev 110(1):132–145

Georgiou K, Koutsioukis A, Georgakilas V (2021) Transparent conductive film of polyvinyl alcohol: reduced graphene oxide composite. J Mater Sci 56(30):17028–17039

Wang P, Jian M, Zhang C, Wu M, Ling X, Zhang J, Wei B, Yang L (2022) Highly stable graphene-based flexible hybrid transparent conductive electrodes for organic solar cells. Adv Mater Interfaces 9(3):2101442

Dunham B, Bal D, Jo Y, Wang Y, Dimitrakopoulos C (2021) Monolayer CVD graphene barrier enhances the stability of planar p-i-n organic-inorganic metal halide perovskite solar cells. ACS Appl. Energy Mater. 5(1):52–60

Wang X, Yuan Y, Xie X, Zhang Y, Min C, Yuan X (2022) Graphene-based OPTO-thermoelectric tweezers. Adv Mater 34(8):2107691

Lee MB, Lee CT, Chong WWF, Chong CT, Sanip SM (2022) Surface morphology and nanofriction of thermally treated multilayer graphene. Int J Surf Sci Eng 16(4):349–366

Ullah N, Qureshi MT, Toufiq AM, Ullah F, Al Elaimi M, Hameed RSA, Khan A, Ragab HME (2021) Effect of cobalt doping on the structural, optical and antibacterial properties of \(\alpha\)-mno 2 nanorods. Appl Phys A 127:1–7

Chen Y, Feng J, Dong FX, Li YF, Bi YG, Yue YY, Sun HB (2016) A two-step thermal annealing and HNO3 doping treatment for graphene electrode and its application in small-molecule organic solar cells. Org Electron 38:35–41

Edwards RS, Coleman KS (2013) Graphene synthesis: relationship to applications. Nanoscale 5(1):38–51

Shams SS, Zhang R, Zhu J (2015) Graphene synthesis: a review. Mater Sci Poland 33(3):566–578

Li X, Zhu Y, Cai W, Borysiak M, Han B, Chen D, Piner RD, Colombo L, Ruoff RS (2009) Transfer of large-area graphene films for high-performance transparent conductive electrodes. Nano Lett 9(12):4359–4363

Chan SH, Chen JW, Chen HP, Wei HS, Li MC, Chen SH, Lee CC, Kuo CC (2014) The deviation of growth model for transparent conductive graphene. Nanoscale Res Lett 9(1):1–6

Golanski L, Rouchon D, Okuno H, Fugier P (2016) Graphene monolayer produced on PT reusable substrates for transparent conductive electrodes applications. Int J Nanotechnol 13(8–9):678–684

Du L, Yang L, Hu Z, Zhang J, Huang C, Sun L, Wang L, Wei D, Chen G, Lu W (2018) Thickness-controlled direct growth of nanographene and nanographite film on non-catalytic substrates. Nanotechnology 29(21):215711

Li X, Cai W, An J, Kim S, Nah J, Yang D, Piner R, Velamakanni A, Jung I, Tutuc E, Banerjee SK, Colombo L, Ruoff RS (2009) Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 324(5932):1312–1314

Liang X, Sperling BA, Calizo I, Cheng G, Hacker CA, Zhang Q, Obeng Y, Yan K, Peng H, Li Q, Zhu X, Yuan H, Hight Walker AR, Liu Z, Peng LM, Richter CA (2011) Toward clean and crackless transfer of graphene. ACS Nano 5(11):9144–9153

Nan HY, Ni ZH, Wang J, Zafar Z, Shi ZX, Wang YY (2013) The thermal stability of graphene in air investigated by Raman spectroscopy. J Raman Spectrosc 44(7):1018–1021

Halme J, Mäkinen P (2019) Theoretical efficiency limits of ideal coloured opaque photovoltaics. Energy Environ Sci 12(4):1274–1285

Elmas S, Pat S, Mohammadigharehbagh R, Musaoğlu C, Özgür M, Demirkol U, Özen S, Korkmaz Ş (2019) Determination of physical properties of graphene doped ZNO (ZNO: Gr) nanocomposite thin films deposited by a thermionic vacuum arc technique. Physica B 557:27–33

Paillet M, Parret R, Sauvajol JL, Colomban P (2018) Graphene and related 2D materials: an overview of the Raman studies. J Raman Spectrosc 49(1):8–12

Ramm M, Ata M, Gross T, Unger W (2000) X-ray photoelectron spectroscopy and near-edge X-ray-absorption fine structure of c60 polymer films. Appl Phys A 70(4):387–390

Yang X, Zhang G, Prakash J, Chen Z, Gauthier M, Sun S (2019) Chemical vapour deposition of graphene: layer control, the transfer process, characterisation, and related applications. Int Rev Phys Chem 38(2):149–199

Ferrari AC (2002) Determination of bonding in diamond-like carbon by Raman spectroscopy. Diam Relat Mater 11(3–6):1053–1061

Kato H, Itagaki N, Im HJ (2019) Growth and Raman spectroscopy of thickness-controlled rotationally faulted multilayer graphene. Carbon 141:76–82

Wang Z, Yao Q, Eigler S (2020) Room-temperature transport properties of graphene with defects derived from OXO-graphene. Chemistry (Weinheim an der Bergstrasse, Germany) 26(29):6484

Malard LM, Moreira RL, Elias DC, Plentz F, Alves ES, Pimenta MA (2010) Thermal enhancement of chemical doping in graphene: a Raman spectroscopy study. J Phys: Condens Matter 22(33):334202

Larsen MBBS, Mackenzie DMA, Caridad JM, Bøggild P, Booth TJ (2014) Transfer induced compressive strain in graphene: evidence from Raman spectroscopic mapping. Microelectron Eng 121:113–117

Yu Q, Jauregui LA, Wu W, Colby R, Tian J, Su Z, Cao H, Liu Z, Pandey D, Wei D, Chung TF, Peng P, Guisinger NP, Stach EA, Bao J, Pei SS, Chenothers YP (2011) Control and characterization of individual grains and grain boundaries in graphene grown by chemical vapour deposition. Nat Mater 10(6):443–449

Tu Z, Liu Z, Li Y, Yang F, Zhang L, Zhao Z, Xu C, Wu S, Liu H, Yang H, Richard P (2014) Controllable growth of 1–7 layers of graphene by chemical vapour deposition. Carbon 73:252–258

Hao Q, Morton SM, Wang B, Zhao Y, Jensen L, Huang TJ (2013) Tuning surface-enhanced Raman scattering from graphene substrates using the electric field effect and chemical doping. Appl Phys Lett 102(1):011102

Das A, Pisana S, Chakraborty B, Piscanec S, Saha SK, Waghmare UV, Novoselov KS, Krishnamurthy HR, Geim AK, Ferrari AC, Sood AK (2008) Monitoring dopants by Raman scattering in an electrochemically top-gated graphene transistor. Nat Nanotechnol 3(4):210–215

Ni ZH, Yu T, Lu YH, Wang YY, Feng YP, Shen ZX (2008) Uniaxial strain on graphene: Raman spectroscopy study and band-gap opening. ACS Nano 2(11):2301–2305

Bautista-Flores C, Sato-Berrú RY, Mendoza D (2018) Raman spectroscopy of CVD graphene during transfer process from copper to SiO2/Si substrates. Mater Res Express 6(1):015601

Verhagen TGA, Drogowska K, Kalbac M, Vejpravova J (2015) Temperature-induced strain and doping in monolayer and bilayer isotopically labeled graphene. Phys Rev B 92(12):125437

Lee JE, Ahn G, Shim J, Lee YS, Ryu S (2012) Optical separation of mechanical strain from charge doping in graphene. Nat Commun 3(1):1–8

Zeng X, Peng Y, Yu M, Lang H, Cao X, Zou K (2018) Dynamic sliding enhancement on the friction and adhesion of graphene, graphene oxide, and fluorinated graphene. ACS Appl Mater Interfaces 10(9):8214–8224

Choi W, Seo YS, Park JY, Kim KB, Jung J, Lee N, Seo Y, Hong S (2014) Effect of annealing in Ar/H2 environment on chemical vapor deposition-grown graphene transferred with poly (methyl methacrylate). IEEE Trans Nanotechnol 14(1):70–74

Wu Z, Zhang X, Das A, Liu J, Zou Z, Zhang Z, Xia Y, Zhao P, Wang H (2019) Step-by-step monitoring of CVD-graphene during wet transfer by Raman spectroscopy. RSC Adv 9(71):41447–41452

Gu M, Lv L, Du F, Niu T, Chen T, Xia D, Wang S, Zhao X, Liu J, Liu Y, Xiong C, Zhou Y (2018) Effects of thermal treatment on the adhesion strength and osteoinductive activity of single-layer graphene sheets on titanium substrates. Sci Rep 8(1):1–15

Liu F, Wang M, Chen Y, Gao J (2019) Thermal stability of graphene in inert atmosphere at high temperature. J Solid State Chem 276:100–103

Park H, Lim C, Lee CJ, Kang J, Kim J, Choi M, Park H (2018) Optimized poly (methyl methacrylate)-mediated graphene-transfer process for fabrication of high-quality graphene layer. Nanotechnology 29(41):415303

Acknowledgements

The authors would like to acknowledge the support provided by the Research University Grant (RUG) of Universiti Teknologi Malaysia (UTM) through the UTM Fundamental Research Grant (Q.J130000.3851.22H02 and PY/2022/00419).

Author information

Authors and Affiliations

Contributions

MBL and WWFC provide conception; MBL and CTL done experimental design; MBL and CTL did carrying out measurements; MBL and CTL gave formal analysis and investigation; MBL did writing—original draft preparation; WWFC and KJW performed writing—review and editing; WWFC did funding acquisition; KJW and WWFC conducted resources; Supervision done by WWFC.

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not applicable.

Additional information

Communicated by Yaroslava Yingling.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, M.B., Lee, C.T., Chong, W.W.F. et al. Post-thermal annealed monolayer graphene healing elucidated by Raman spectroscopy. J Mater Sci 58, 10288–10302 (2023). https://doi.org/10.1007/s10853-023-08685-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08685-z