Abstract

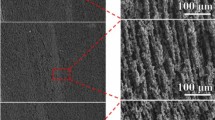

As a kind of inorganic filler, boron carbide powder-toughened polymer matrix has been widely studied. However, the layered boron carbide scaffold composites with large area orientation are rarely reported. A series of hierarchically aligned scaffolds of boron carbide and polyvinyl alcohol (B4C/PVA) with different B4C mass fractions are prepared by a bidirectional freeze-casting method. These ordered, lamellar B4C/PVA scaffolds allow paraffin wax to penetrate rapidly to form composite phase change materials (CPCMs). The molten paraffin trapped in this structure remains stable and has a little amount of leakage because of capillary effect. And the leakage rate is 1.1 wt% and 1.6 wt% after 25 cycles at the temperature interval of 25–80 °C and 25–90 °C, respectively. The highest retention of latent heat is up to 90% for specimen of 1%-a. And the thermal conductivity of CPCMs is 0.33 W m−1 K−1 for 8%-e.

Graphical abstract

Hierarchically aligned B4C/PVA scaffolds fabricated by bidirectional freeze casting can improve structure stability of PCMs and hamper the leakage of paraffin.

Similar content being viewed by others

References

Mills A, Farid M, Selman JR, Al-Hallaj S (2006) Thermal conductivity enhancement of phase change materials using a graphite matrix. Appl Therm Eng 26:1652

Taghilou M, Khavasi E (2020) Thermal behavior of a PCM filled heat sink: the contrast between ambient heat convection and heat thermal storage. Appl Therm Eng 174:115273. https://doi.org/10.1016/j.applthermaleng.2020.115273

Kenisarin M, Mahkamov K (2016) Passive thermal control in residential buildings using phase change materials. Renew Sustain Energy Rev 55:371. https://doi.org/10.1016/j.rser.2015.10.128

Akeiber H, Nejat P, Majid MZA et al (2016) A review on phase change material (PCM) for sustainable passive cooling in building envelopes. Renew Sustain Energy Rev 60:1470. https://doi.org/10.1016/j.rser.2016.03.036

Nagano K, Ogawa K, Mochida T, Hayashi K, Ogoshi H (2004) Thermal characteristics of magnesium nitrate hexahydrate and magnesium chloride hexahydrate mixture as a phase change material for effective utilization of urban waste heat. Appl Therm Eng 24:221

Johansson MT, Söderström M (2014) Electricity generation from low-temperature industrial excess heat—an opportunity for the steel industry. Energ Effi 7:203. https://doi.org/10.1007/s12053-013-9218-6

Aftab W, Huang X, Wu W, Liang Z, Mahmood A, Zou R (2018) Nanoconfined phase change materials for thermal energy applications. Energy Environ Sci 11:1392. https://doi.org/10.1039/C7EE03587J

Sari A, Alkan C, Bilgin C (2014) Micro/nano encapsulation of some paraffin eutectic mixtures with poly(methyl methacrylate) shell: preparation, characterization and latent heat thermal energy storage properties. Appl Energy 136:217

Fang Y, Liu X, Liang X, Liu H, Gao X, Zhang Z (2014) Ultrasonic synthesis and characterization of polystyrene/n-dotriacontane composite nanoencapsulated phase change material for thermal energy storage. Appl Energy 132:551

Haase MF, Grigoriev D, Moehwald H, Tiersch B, Shchukin DG (2011) Nanoparticle modification by weak polyelectrolytes for pH-sensitive pickering emulsions. Langmuir 27:74

Zhang H, Li W, Huang R, Wang N, Wang J, Zhang X (2017) Microstructure regulation of microencapsulated bio-based n-dodecanol as phase change materials via in situ polymerization. New J Chem 41:14696. https://doi.org/10.1039/C7NJ02864D

Bédard MF, Braun D, Sukhorukov GB, Skirtach AG (2008) Toward self-assembly of nanoparticles on polymeric microshells: near-IR release and permeability. ACS Nano 2:1807. https://doi.org/10.1021/nn8002168

Deville S (2013) Ice-templating, freeze casting: beyond materials processing. J Mater Res 28:2202. https://doi.org/10.1557/jmr.2013.105

Bouville F, Portuguez E, Chang Y et al (2014) Templated grain growth in macroporous materials. J Am Ceram Soc 97:1736. https://doi.org/10.1111/jace.12976

Shchukina EM, Graham M, Zheng Z, Shchukin DG (2018) Nanoencapsulation of phase change materials for advanced thermal energy storage systems. Chem Soc Rev 47:4156. https://doi.org/10.1039/C8CS00099A

Qian Z, Shen H, Fang X, Fan L, Zhao N, Xu J (2018) Phase change materials of paraffin in h-BN porous scaffolds with enhanced thermal conductivity and form stability. Energy Build 158:1184. https://doi.org/10.1016/j.enbuild.2017.11.033

Andriamitantsoa RS, Dong W, Gao H, Wang G (2017) Porous organic–inorganic hybrid xerogels for stearic acid shape-stabilized phase change materials. New J Chem 41:1790. https://doi.org/10.1039/C6NJ03034C

Sun Z, Liao T, Li W, Qiao Y, Ostrikov K (2019) Beyond seashells: bioinspired 2D photonic and photoelectronic devices. Adv Func Mater. https://doi.org/10.1002/adfm.201901460

Liu J, Yang H, Liu K, Miao R, Fang Y (2020) Gel–emulsion-templated polymeric aerogels for water treatment by organic liquid removal and solar vapor generation. Chemsuschem 13:749. https://doi.org/10.1002/cssc.201902970

Xiao X, Zhang P, Li M (2013) Preparation and thermal characterization of paraffin/metal foam composite phase change material. Appl Energy 112:1357. https://doi.org/10.1016/j.apenergy.2013.04.050

Han J, Du G, Gao W, Bai H (2019) An anisotropically high thermal conductive boron nitride/epoxy composite based on nacre-mimetic 3D network. Adv Func Mater. https://doi.org/10.1002/adfm.201900412

Wang M, Zhang T, Mao D et al (2019) Highly compressive boron nitride nanotube aerogels reinforced with reduced graphene oxide. ACS Nano 13:7402. https://doi.org/10.1021/acsnano.9b03225

Yang J, Tang L-S, Bai L et al (2018) Photodriven shape-stabilized phase change materials with optimized thermal conductivity by tailoring the microstructure of hierarchically ordered hybrid porous scaffolds. ACS Sustain Chem Eng 6:6761. https://doi.org/10.1021/acssuschemeng.8b00565

Chen X, Gao H, Yang M et al (2018) Highly graphitized 3D network carbon for shape-stabilized composite PCMs with superior thermal energy harvesting. Nano Energy 49:86. https://doi.org/10.1016/j.nanoen.2018.03.075

Zhang L, Zhou K, Wei Q et al (2019) Thermal conductivity enhancement of phase change materials with 3D porous diamond foam for thermal energy storage. Appl Energy 233–234:208. https://doi.org/10.1016/j.apenergy.2018.10.036

Min P, Liu J, Li X et al (2018) Thermally conductive phase change composites featuring anisotropic graphene aerogels for real-time and fast-charging solar-thermal energy conversion. Adv Func Mater 28:1805365. https://doi.org/10.1002/adfm.201805365

Gao W, Zhao N, Yu T et al (2020) High-efficiency electromagnetic interference shielding realized in nacre-mimetic graphene/polymer composite with extremely low graphene loading. Carbon 157:570. https://doi.org/10.1016/j.carbon.2019.10.051

Fu Q, Wen L, Zhang L, Chen X, Zhang H (2019) Porous carbon and carbon/metal oxide composites by ice templating and subsequent pyrolysis. Ind Eng Chem Res 58:14312. https://doi.org/10.1021/acs.iecr.9b01081

Yin H, Gao S, Liao C et al (2019) Self-assembly of 3D-graphite block infiltrated phase change materials with increased thermal conductivity. J Clean Prod 235:359. https://doi.org/10.1016/j.jclepro.2019.06.355

Du G, Mao A, Yu J et al (2019) Nacre-mimetic composite with intrinsic self-healing and shape-programming capability. Nat Commun 10:800. https://doi.org/10.1038/s41467-019-08643-x

Yang M, Zhao N, Cui Y et al (2017) Biomimetic architectured graphene aerogel with exceptional strength and resilience. ACS Nano 11:6817. https://doi.org/10.1021/acsnano.7b01815

Bai H, Walsh F, Gludovatz B et al (2016) Bioinspired hydroxyapatite/poly(methyl methacrylate) composite with a nacre-mimetic architecture by a bidirectional freezing method. Adv Mater 28:50. https://doi.org/10.1002/adma.201504313

Bai H, Chen Y, Delattre B, Tomsia AP, Ritchie RO (2015) Bioinspired large-scale aligned porous materials assembled with dual temperature gradients. Sci Adv. https://doi.org/10.1126/sciadv.1500849

Waschkies T, Oberacker R, Hoffmann MJ (2011) Investigation of structure formation during freeze-casting from very slow to very fast solidification velocities. Acta Mater 59:5135. https://doi.org/10.1016/j.actamat.2011.04.046

Acknowledgements

The authors thank Analytical and Testing Centre of Southwest University of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Handling Editor: Dale Huber.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, C., Wei, C., Bai, J. et al. Paraffin-filled boron carbide/polyvinyl alcohol scaffolds with enhanced thermal energy storage and form stability. J Mater Sci 56, 13259–13270 (2021). https://doi.org/10.1007/s10853-021-06153-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06153-0