Abstract

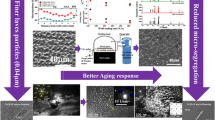

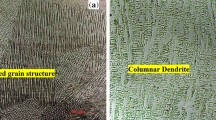

The effect of post-weld solution along with different double aging treatments on precipitation of various strengthening phases in Alloy 718 weld is carried out in the current assessment. The formation of intermetallic phases in the weld zone deteriorates the mechanical properties and quality of the weld joint. The high-temperature solution treatment at 1165 °C/1 h has dissolved the intermetallic phases and makes a suitable quantity of alloying elements accessible for precipitation of the strengthening phases. To analyze the impact of aging temperature and holding time on δ, γ' and γ" phase precipitation, four different heat treatment paths are designed. The heat treatment holding time is reduced by 53% on the welded component by applying a higher aging temperature compared to the conventional standard aging temperatures. The variation in aging temperature and holding time followed by solution treatment changes the platelet morphology of the δ phase to needle shape in the grain boundary. Significant enhancement in the tensile strength (21%) and weld hardness (121%) is witnessed due to duplex aging treatment compared to as-welded condition. The XRD analysis confirms the precipitation of γ' and γ'' strengthening phases inside the grain and δ particles in the grain boundaries.

Graphical abstract

Similar content being viewed by others

References

Manikandan SGK, Sivakumar D, Prasad Rao K, Kamaraj M (2015) Laves phase in alloy 718 fusion zone—microscopic and calorimetric studies. Mater Charact 100:192–206

Texier D, Cormier J, Villechaise P et al (2016) Crack initiation sensitivity of wrought direct aged alloy 718 in the very high cycle fatigue regime: the role of non-metallic inclusions. Mater Sci Eng A 678:122–136

Pereira JM, Lerch BA (2001) Effects of heat treatment on the ballistic impact properties of Inconel 718 for jet engine fan containment applications. Int J Impact Eng 25:715–733

Knorovsky GA, Cieslak MJ, Headley TJ et al (1989) INCONEL 718: a solidification diagram. Metall Mater Trans A 20:2149–2158

Sahu AK, Bag S, Huang K (2020) Mitigation of micro-cracks in dissimilar welding of Inconel 718 and austenitic stainless steel. Philoso Mag Lett 100:365–374

Sahu AK, Bag S (2019) Finite element modelling and experimental verification of dissimilar joining between inconel 718 and SS 316L by Micro-plasma Arc welding. In: Narayanan RG, Joshi SN, Dixit US (eds) Advances in computational methods in manufacturing. Springer, Singapore, pp 231–243

Mei Y, Liu Y, Liu C et al (2016) Effect of base metal and welding speed on fusion zone microstructure and HAZ hot-cracking of electron-beam welded Inconel 718. Mater Des 89:964–977

Phillips PJ, McAllister D, Gao Y et al (2012) Nano γ′/γ″ composite precipitates in Alloy 718. Appl Phys Lett 100:211913

McAllister D, Lv D, Peterson B et al (2016) Lower temperature deformation mechanisms in a γ″-strengthened Ni-base superalloy. Scripta Mater 115:108–112

Qi H, Azer M, Ritter A (2009) Studies of standard heat treatment effects on microstructure and mechanical properties of laser net shape manufactured INCONEL 718. Metall Mater Trans A 40:2410–2422

Kuo C-M, Yang Y-T, Bor H-Y et al (2009) Aging effects on the microstructure and creep behavior of Inconel 718 superalloy. Mater Sci Eng A 510–511:289–294

Sahu AK, Bag S (2020) Probe pulse conditions and solidification parameters for the dissimilar welding of inconel 718 and AISI 316L stainless steel. Metall and Mat Trans A 51:2192–2208

Manikandan SGK, Sivakumar D, Rao KP, Kamaraj M (2014) Effect of weld cooling rate on Laves phase formation in Inconel 718 fusion zone. J Mater Process Technol 214:358–364

Odabaşı A, Ünlü N, Göller G, Eruslu MN (2010) A study on laser beam welding (LBW) technique: effect of heat input on the microstructural evolution of superalloy inconel 718. Metall Mat Trans A 41:2357–2365

Ram GDJ, Reddy AV, Rao KP, Reddy GM (2005) Microstructure and mechanical properties of Inconel 718 electron beam welds. Mater Sci Technol 21:1132–1138

Gobbi S, Zhang L, Norris J et al (1996) High powder CO2 and NdYAG laser welding of wrought Inconel 718. J Mater Process Technol 56:333–345

Madhusudhana Reddy G, Srinivasa Murthy CV, Srinivasa Rao K, Prasad Rao K (2009) Improvement of mechanical properties of Inconel 718 electron beam welds—influence of welding techniques and postweld heat treatment. Int J Adv Manuf Technol 43:671–680

Thompson RG, Dobbs JR, Mayo DE (1986) The effect of heat treatment on microfissuring in alloy 718. Weld J 65:299s–304s

Sahu AK, Bag S (2020) Effect of pre-weld solution treatment on mechanical properties and microstructure of micro-plasma arc welded inconel 718. In: Shunmugam MS, Kanthababu M (eds) Advances in additive manufacturing and joining. Springer, Singapore, pp 373–383

Shi R, McAllister DP, Zhou N et al (2019) Growth behavior of γ’/γ’’ coprecipitates in Ni-Base superalloys. Acta Mater 164:220–236

Theska F, Stanojevic A, Oberwinkler B et al (2018) On conventional versus direct ageing of Alloy 718. Acta Mater 156:116–124

Banerjee K, Richards NL, Chaturvedi MC (2005) Effect of filler alloys on heat-affected zone cracking in preweld heat-treated IN-738 LC gas-tungsten-arc welds. Metall Mat Trans A 36:1881–1890

Qian M, Lippold JC (2003) The effect of rejuvenation heat treatments on the repair weldability of wrought Alloy 718. Mater Sci Eng A 340:225–231

Niang A, Viguier B, Lacaze J (2010) Some features of anisothermal solid-state transformations in alloy 718. Mater Charact 61:525–534

Tucho WM, Cuvillier P, Sjolyst-Kverneland A, Hansen V (2017) Microstructure and hardness studies of Inconel 718 manufactured by selective laser melting before and after solution heat treatment. Mater Sci Eng A 689:220–232

Cao X, Rivaux B, Jahazi M et al (2009) Effect of pre- and post-weld heat treatment on metallurgical and tensile properties of Inconel 718 alloy butt joints welded using 4 kW Nd:YAG laser. J Mater Sci 44:4557–4571. https://doi.org/10.1007/s10853-009-3691-5

Richards NL, Huang X, Chaturvedi MC (1992) Heat affected zone cracking in cast inconel 718. Mater Charact 28:179–187

Sundararaman M, Mukhopadhyay P (1993) Carbide precipitation in Inconel 718. High Temp Mater Process (London) 11:351–368

Theska F, Stanojevic A, Oberwinkler B, Primig S (2020) Microstructure-property relationships in directly aged Alloy 718 turbine disks. Mater Sci Eng A 776:138967

Texier D, Gómez AC, Pierret S et al (2016) Microstructural features controlling the variability in low-cycle fatigue properties of alloy inconel 718DA at intermediate temperature. Metall Mater Trans A 47:1096–1109

Zhou N, Lv DC, Zhang HL et al (2014) Computer simulation of phase transformation and plastic deformation in IN718 superalloy: Microstructural evolution during precipitation. Acta Mater 65:270–286

Ahmadi MR, Rath M, Povoden-Karadeniz E et al (2017) Modeling of precipitation strengthening in Inconel 718 including non-spherical γ″ precipitates. Model Simul Mater Sci Eng 25:055005

Drexler A, Oberwinkler B, Primig S et al (2018) Experimental and numerical investigations of the γ″ and γ′ precipitation kinetics in Alloy 718. Mater Sci Eng A 723:314–323

Cormier J, Gadaud P, Czaplicki M et al (2020) In-situ determination of precipitation kinetics during heat treatment of superalloy 718. Metall Mater Trans A 52:500–511

Jouiad M, Marin E, Devarapalli RS et al (2016) Microstructure and mechanical properties evolutions of alloy 718 during isothermal and thermal cycling over-aging. Mater Des 102:284–296

Bansal A, Vasudev H, Sharma AK, Kumar P (2019) Investigation on the effect of post weld heat treatment on microwave joining of the Alloy-718 weldment. Mater Res Express 6:086554

Seow CE, Coules HE, Wu G et al (2019) Wire + Arc additively manufactured inconel 718: effect of post-deposition heat treatments on microstructure and tensile properties. Mater Des 183:108157

Theska F, Nomoto K, Godor F et al (2020) On the early stages of precipitation during direct ageing of Alloy 718. Acta Mater 188:492–503

Detor AJ, DiDomizio R, Sharghi-Moshtaghin R et al (2018) Enabling large superalloy parts using compact coprecipitation of γ′ and γ′′. Metall Mater Trans A 49:708–717

Acknowledgement

The authors are grateful to the Mechanical Engineering Department, Central Workshop and Central Instrument Facility (CIF) of IIT Guwahati for providing the experimental facility to perform the present research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Sophie Primig.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sahu, A.K., Bag, S. Design of a double aging treatment for the improvement of mechanical and microstructural properties of pulse micro-plasma arc welded alloy 718. J Mater Sci 56, 13400–13415 (2021). https://doi.org/10.1007/s10853-021-06121-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06121-8