Abstract

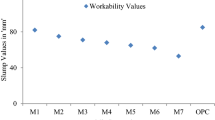

Momentous issues like interminable manufacturing of cement, liberating colossal quantities of CO2 into the atmosphere, and enormous discarding of granite waste by various industries disturbing the ecological system are provoking to be an issue of global warming worldwide. This research has focused on efficacious reutilization of granite waste in the preparation of fly ash-based geopolymer concrete. Granite waste was reutilized as fractional replacement of natural fine aggregates (sand) in varied proportions from 0 to 20% by weight in 5% incremental order. The performance evaluation of geopolymer concrete incorporated with granite waste was carried out through strength and durability studies such as dry density, compressive strength, ultrasonic pulse velocity, modulus of elasticity, water permeability, chloride penetration depth, acid attack, and carbonation. Geopolymer concrete’s mass change was determined using thermogravimetric analysis and differential thermogravimetry. Reutilization of granite waste in the preparation of fly ash-based geopolymer concrete provides solution for issues related to waste management and improved several geopolymer concrete’s properties. All the strength and durability test results divulged that geopolymer concrete prepared with granite waste up to 15% substitution of natural fine aggregates possessed superiority regarding mechanical properties and durability characteristics in contrast with control geopolymer concrete.

Similar content being viewed by others

References

Aarthi, K., & Arunachalam, K. (2018). Durability studies on fibre reinforced self compacting concrete with sustainable wastes. Journal of Cleaner Production, 174, 247–255.

Adak, D., Sarkar, M., & Mandal, S. (2017). Structural performance of nano-silica modified fly-ash based geopolymer concrete. Construction and Building Materials, 135, 430–439.

Al-Azzawi, M., Yu, T., & Hadi, M. N. (2018). June). Factors affecting the bond strength between the fly ash-based geopolymer concrete and steel reinforcement. Structure, 14, 262–272.

Albitar, M., Ali, M. M., Visintin, P., & Drechsler, M. (2015). Effect of granulated lead smelter slag on strength of fly ash-based geopolymer concrete. Construction and Building Materials, 83, 128–135.

Aliabdo, A. A., Abd Elmoaty, M., & Auda, E. M. (2014). Re-use of waste marble dust in the production of cement and concrete. Construction and Building Materials, 50, 28–41.

Aliabdo, A. A., Abd Elmoaty, M., & Salem, H. A. (2016). Effect of cement addition, solution resting time and curing characteristics on fly ash based geopolymer concrete performance. Construction and Building Materials, 123, 581–593.

Al-Majidi, M. H., Lampropoulos, A. P., Cundy, A. B., Tsioulou, O. T., & Alrekabi, S. (2019). Flexural performance of reinforced concrete beams strengthened with fibre reinforced geopolymer concrete under accelerated corrosion. Structures, 19, 394–410.

Aly, A. M., El-Feky, M. S., Kohail, M., & Nasr, E. S. A. (2019). Performance of geopolymer concrete containing recycled rubber. Construction and Building Materials, 207, 136–144.

Ariffin, M. A. M., Bhutta, M. A. R., Hussin, M. W., Tahir, M. M., & Aziah, N. (2013). Sulfuric acid resistance of blended ash geopolymer concrete. Construction and building materials, 43, 80–86.

ASTM:C1202. (2007). Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration.

ASTM:C267-01. (2012). Standard test methods for chemical resistance of mortars, grouts, and monolithic surfacings and polymer concretes.

ASTM:C469. (1994). Standard test method for static modulus of elasticity and Poisson's ratio of concrete in compression.

Binici, H., Shah, T., Aksogan, O., & Kaplan, H. (2008). Durability of concrete made with granite and marble as recycle aggregates. Journal of Materials Processing Technology, 208(1–3), 299–308.

BIS:1199. (1959). Methods of sampling and analysis of concrete.

BIS:13311. (1992). Indian standard non-destructive testing of concrete Method of test Ultrasonic pulse velocity.

BIS:383. (2016). Specification for coarse and fine aggregates from natural sources for concrete, Bureau of Indian Standards, New Delhi, India.

BIS:516. (1959). Methods of tests for strength of concrete, Bureau of Indian Standards, New Delhi, India.

Bisht, K., & Ramana, P. V. (2019). Waste to resource conversion of crumb rubber for production of sulphuric acid resistant concrete. Construction and Building Materials, 194, 276–286.

Bouaissi, A., Li, L. Y., Abdullah, M. M. A. B., & Bui, Q. B. (2019). Mechanical properties and microstructure analysis of FA-GGBS-HMNS based geopolymer concrete. Construction and Building Materials, 210, 198–209.

Cheah, C. B., Lim, J. S., & Ramli, M. B. (2019). The mechanical strength and durability properties of ternary blended cementitious composites containing granite quarry dust (GQD) as natural sand replacement. Construction and Building Materials, 197, 291–306.

Chindaprasirt, P., & Rattanasak, U. (2010). Utilization of blended fluidized bed combustion (FBC) ash and pulverized coal combustion (PCC) fly ash in geopolymer. Waste Management, 30(4), 667–672.

CPC:18. (1988). Measurement of hardened concrete carbonation depth.

Deb, P. S., Nath, P., & Sarker, P. K. (2014). The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Materials and Design, 1980–2015(62), 32–39.

DIN:1048. (1991). Testing concrete: testing of hardened concrete specimens prepared in mould, Part 5, Deutsches Institut fur Normung, Germany.

Ganesan, N., Abraham, R., & Raj, S. D. (2015). Durability characteristics of steel fibre reinforced geopolymer concrete. Construction and Building Materials, 93, 471–476.

Ghannam, S., Najm, H., & Vasconez, R. (2016). Experimental study of concrete made with granite and iron powders as partial replacement of sand. Sustainable Materials and Technologies, 9, 1–9.

Gulsan, M. E., Alzeebaree, R., Rasheed, A. A., Nis, A., & Kurtoglu, A. E. (2019). Development of fly ash/slag based self-compacting geopolymer concrete using nano-silica and steel fiber. Construction and Building Materials, 211, 271–283.

Gupta, L. K., & Vyas, A. K. (2018). Impact on mechanical properties of cement sand mortar containing waste granite powder. Construction and Building Materials, 191, 155–164.

Gupta, T., Chaudhary, S., & Sharma, R. K. (2016). Mechanical and durability properties of waste rubber fiber concrete with and without silica fume. Journal of Cleaner Production, 112, 702–711.

Gupta, T., Patel, K. A., Siddique, S., Sharma, R. K., & Chaudhary, S. (2019). Prediction of mechanical properties of rubberised concrete exposed to elevated temperature using ANN. Measurement, 147, 106870.

Gupta, T., Sharma, R. K., & Chaudhary, S. (2015). Influence of waste tyre fibers on strength, abrasion resistance and carbonation of concrete. Scientia Iranica, 22(4), 1481–1489.

Gupta, T., Siddique, S., Sharma, R. K., & Chaudhary, S. (2018). Lateral force microscopic examination of calcium silicate hydrate in rubber ash concrete. Construction and Building Materials, 179, 461–467.

Hassan, A., Mourad, A. H. I., Rashid, Y., Ismail, N., & Laghari, M. S. (2019). Thermal and structural performance of geopolymer concrete containing phase change material encapsulated in expanded clay. Energy and Buildings, 191, 72–81.

Huiskes, D. M. A., Keulen, A., Yu, Q. L., & Brouwers, H. J. H. (2016). Design and performance evaluation of ultra-lightweight geopolymer concrete. Materials and Design, 89, 516–526.

Hussin, M. W., Bhutta, M. A. R., Azreen, M., Ramadhansyah, P. J., & Mirza, J. (2015). Performance of blended ash geopolymer concrete at elevated temperatures. Materials and Structures, 48(3), 709–720.

Jain, A., Choudhary, R., Gupta, R., & Chaudhary, S. (2020a). Abrasion resistance and sorptivity characteristics of SCC containing granite waste. Materials Today: Proceedings, 27, 524–528.

Jain, A., Gupta, R., & Chaudhary, S. (2019). Performance of self-compacting concrete comprising granite cutting waste as fine aggregate. Construction and Building Materials, 221, 539–552.

Jain, A., Gupta, R., & Chaudhary, S. (2020b). Sustainable development of self-compacting concrete by using granite waste and fly ash. Construction and Building Materials, 262, 120516.

Jain, A., Siddique, S., Gupta, T., Sharma, R. K., & Chaudhary, S. (2020c). Utilization of shredded waste plastic bags to improve impact and abrasion resistance of concrete. Environment, Development and Sustainability, 22(1), 337–362.

Jain, K. L., Sancheti, G., & Gupta, L. K. (2020d). Durability performance of waste granite and glass powder added concrete. Construction and Building Materials, 252, 119075.

Jena, S., & Panigrahi, R. (2019). Performance assessment of geopolymer concrete with partial replacement of ferrochrome slag as coarse aggregate. Construction and Building Materials, 220, 525–537.

Khan, I., Xu, T., Castel, A., Gilbert, R. I., & Babaee, M. (2019). Risk of early age cracking in geopolymer concrete due to restrained shrinkage. Construction and Building Materials, 229, 116840.

Kondepudi, K., & Subramaniam, K. V. (2019). Rheological characterization of low-calcium fly ash suspensions in alkaline silicate colloidal solutions for geopolymer concrete production. Journal of Cleaner Production, 234, 690–701.

Kong, D. L., & Sanjayan, J. G. (2010). Effect of elevated temperatures on geopolymer paste, mortar and concrete. Cement and Concrete Research, 40(2), 334–339.

Koushkbaghi, M., Alipour, P., Tahmouresi, B., Mohseni, E., Saradar, A., & Sarker, P. K. (2019). Influence of different monomer ratios and recycled concrete aggregate on mechanical properties and durability of geopolymer concretes. Construction and Building Materials, 205, 519–528.

Lee, W. H., Wang, J. H., Ding, Y. C., & Cheng, T. W. (2019). A study on the characteristics and microstructures of GGBS/FA based geopolymer paste and concrete. Construction and Building Materials, 211, 807–813.

Li, N., Shi, C., Zhang, Z., Wang, H., & Liu, Y. (2019). A review on mixture design methods for geopolymer concrete. Composites Part B: Engineering, 178, 107490.

Liu, Y., Shi, C., Zhang, Z., Li, N., & Shi, D. (2020). Mechanical and fracture properties of ultra-high performance geopolymer concrete: Effects of steel fiber and silica fume. Cement and Concrete Composites, 112, 103665.

Luhar, S., Chaudhary, S., & Luhar, I. (2018). Thermal resistance of fly ash based rubberized geopolymer concrete. Journal of Building Engineering, 19, 420–428.

Luhar, S., Chaudhary, S., & Luhar, I. (2019). Development of rubberized geopolymer concrete: Strength and durability studies. Construction and Building Materials, 204, 740–753.

Ma, C. K., Awang, A. Z., & Omar, W. (2018). Structural and material performance of geopolymer concrete: A review. Construction and Building Materials, 186, 90–102.

Mashaly, A. O., Shalaby, B. N., & Rashwan, M. A. (2018). Performance of mortar and concrete incorporating granite sludge as cement replacement. Construction and Building Materials, 169, 800–818.

Meng, Q., Wu, C., Su, Y., Li, J., Liu, J., & Pang, J. (2019). A study of steel wire mesh reinforced high performance geopolymer concrete slabs under blast loading. Journal of Cleaner Production, 210, 1150–1163.

Mesgari, S., Akbarnezhad, A., & Xiao, J. Z. (2020). Recycled geopolymer aggregates as coarse aggregates for Portland cement concrete and geopolymer concrete: Effects on mechanical properties. Construction and Building Materials, 236, 117571.

Mimboe, A. G., Abo, M. T., Djobo, J. N. Y., Tome, S., Kaze, R. C., & Deutou, J. G. N. (2020). Lateritic soil based-compressed earth bricks stabilized with phosphate binder. Journal of Building Engineering, 31, 101465.

Muttashar, H. L., Ariffin, M. A. M., Hussein, M. N., Hussin, M. W., & Ishaq, S. B. (2018). Self-compacting geopolymer concrete with spend garnet as sand replacement. Journal of Building Engineering, 15, 85–94.

Naqi, A., Siddique, S., Kim, H. K., & Jang, J. G. (2020). Examining the potential of calcined oyster shell waste as additive in high volume slag cement. Construction and Building Materials, 230, 116973.

Nath, P., & Sarker, P. K. (2015). Use of OPC to improve setting and early strength properties of low calcium fly ash geopolymer concrete cured at room temperature. Cement and Concrete Composites, 55, 205–214.

Nemaleu, J. G. D., Djaoyang, V. B., Bilkissou, A., Kaze, C. R., Boum, R. B. E., Djobo, J. N. Y., et al. (2020). Investigation of groundnut shell powder on development of lightweight metakaolin based geopolymer composite: Mechanical and microstructural properties. Silicon. https://doi.org/10.1007/s12633-020-00829-z

Nuaklong, P., Sata, V., & Chindaprasirt, P. (2016). Influence of recycled aggregate on fly ash geopolymer concrete properties. Journal of Cleaner Production, 112, 2300–2307.

Okoye, F. N., Durgaprasad, J., & Singh, N. B. (2016). Effect of silica fume on the mechanical properties of fly ash based-geopolymer concrete. Ceramics International, 42(2), 3000–3006.

Park, Y., Abolmaali, A., Kim, Y. H., & Ghahremannejad, M. (2016). Compressive strength of fly ash-based geopolymer concrete with crumb rubber partially replacing sand. Construction and Building Materials, 118, 43–51.

Part, W. K., Ramli, M., & Cheah, C. B. (2015). An overview on the influence of various factors on the properties of geopolymer concrete derived from industrial by-products. Construction and Building Materials, 77, 370–395.

Pavithra, P. E., Reddy, M. S., Dinakar, P., Rao, B. H., Satpathy, B. K., & Mohanty, A. N. (2016). A mix design procedure for geopolymer concrete with fly ash. Journal of Cleaner Production, 133, 117–125.

Pilehvar, S., Cao, V. D., Szczotok, A. M., Valentini, L., Salvioni, D., & Magistri, M., et al. (2017). Mechanical properties and microscale changes of geopolymer concrete and Portland cement concrete containing micro-encapsulated phase change materials. Cement and Concrete Research, 100, 341–349.

Prusty, J. K., & Pradhan, B. (2020). Multi-response optimization using Taguchi-Grey relational analysis for composition of fly ash-ground granulated blast furnace slag based geopolymer concrete. Construction and Building Materials, 241, 118049.

Reddy, B. M., Reddy, R. M., Reddy, B. C. M., Reddy, P. V., Rao, H. R., & Reddy, Y. M. (2020). The effect of granite powder on mechanical, structural and water absorption characteristics of alkali treated cordia dichotoma fiber reinforced polyester composite. Polymer Testing, 91, 106782.

Ryu, G. S., Lee, Y. B., Koh, K. T., & Chung, Y. S. (2013). The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Construction and Building Materials, 47, 409–418.

Sadek, D. M., El-Attar, M. M., & Ali, H. A. (2016). Reusing of marble and granite powders in self-compacting concrete for sustainable development. Journal of Cleaner Production, 121, 19–32.

Salas, D. A., Ramirez, A. D., Ulloa, N., Baykara, H., & Boero, A. J. (2018). Life cycle assessment of geopolymer concrete. Construction and Building Materials, 190, 170–177.

Savadkoohi, M. S., & Reisi, M. (2020). Environmental protection based sustainable development by utilization of granite waste in Reactive Powder Concrete. Journal of Cleaner Production, 266, 121973.

Saxena, R., Gupta, T., Sharma, R. K., Chaudhary, S., & Jain, A. (2020). Assessment of mechanical and durability properties of concrete containing PET waste. Scientia Iranica, 27(1), 1–9.

Saxena, R., Siddique, S., Gupta, T., Sharma, R. K., & Chaudhary, S. (2018). Impact resistance and energy absorption capacity of concrete containing plastic waste. Construction and Building Materials, 176, 415–421.

Singh, S., Nagar, R., & Agrawal, V. (2016a). Performance of granite cutting waste concrete under adverse exposure conditions. Journal of Cleaner Production, 127, 172–182.

Singh, S., Nagar, R., & Agrawal, V. (2016b). Feasibility as a potential substitute for natural sand: a comparative study between granite cutting waste and marble slurry. Procedia Environmental Sciences, 35, 571–582.

Singh, S., Nagar, R., Agrawal, V., Rana, A., & Tiwari, A. (2016c). Sustainable utilization of granite cutting waste in high strength concrete. Journal of Cleaner Production, 116, 223–235.

Singhal, D., Junaid, M. T., Jindal, B. B., & Mehta, A. (2018). Mechanical and microstructural properties of fly ash based geopolymer concrete incorporating alccofine at ambient curing. Construction and Building Materials, 180, 298–307.

Taji, I., Ghorbani, S., De Brito, J., Tam, V. W., Sharifi, S., Davoodi, A., & Tavakkolizadeh, M. (2019). Application of statistical analysis to evaluate the corrosion resistance of steel rebars embedded in concrete with marble and granite waste dust. Journal of Cleaner Production, 210, 837–846.

Teh, S. H., Wiedmann, T., Castel, A., & de Burgh, J. (2017). Hybrid life cycle assessment of greenhouse gas emissions from cement, concrete and geopolymer concrete in Australia. Journal of Cleaner Production, 152, 312–320.

Thomas, F. K., & Partheeban, P. (2010). Study on the effect of granite powder on concrete properties. Proceedings of the Institution of Civil Engineers-Construction Materials, 163(2), 63–70.

Torres, P., Fernandes, H. R., Agathopoulos, S., Tulyaganov, D. U., & Ferreira, J. M. F. (2004). Incorporation of granite cutting sludge in industrial porcelain tile formulations. Journal of the European Ceramic Society, 24(10–11), 3177–3185.

Upadhyaya, S., Nanda, B., & Panigrahi, R. (2020). Effect of granite dust as partial replacement to natural sand on strength and ductility of reinforced concrete beams. Journal of the Institution of Engineers (India): Series A, 101(4), 669–677.

Vijayalakshmi, M., & Sekar, A. S. S. (2013). Strength and durability properties of concrete made with granite industry waste. Construction and Building Materials, 46, 1–7.

Xie, J., Chen, W., Wang, J., Fang, C., Zhang, B., & Liu, F. (2019). Coupling effects of recycled aggregate and GGBS/metakaolin on physicochemical properties of geopolymer concrete. Construction and Building Materials, 226, 345–359.

Xie, T., & Ozbakkaloglu, T. (2015). Behavior of low-calcium fly and bottom ash-based geopolymer concrete cured at ambient temperature. Ceramics International, 41(4), 5945–5958.

Zafar, M. S., Javed, U., Khushnood, R. A., Nawaz, A., & Zafar, T. (2020). Sustainable incorporation of waste granite dust as partial replacement of sand in autoclave aerated concrete. Construction and Building Materials, 250, 118878.

Zhao, R., Yuan, Y., Cheng, Z., Wen, T., Li, J., Li, F., & Ma, Z. J. (2019). Freeze-thaw resistance of class F fly ash-based geopolymer concrete. Construction and Building Materials, 222, 474–483.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saxena, R., Gupta, T., Sharma, R.K. et al. Influence of granite waste on mechanical and durability properties of fly ash-based geopolymer concrete. Environ Dev Sustain 23, 17810–17834 (2021). https://doi.org/10.1007/s10668-021-01414-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-021-01414-z