Abstract

The entrainment coefficient of the pure plume, the ratio of the radial velocity of the entraining fluid at the edge of the plume to the axial velocity, is characterized by a remarkable deviation from the actual value in references. To a turbulent flow with Gaussian profiles, the entrainment coefficient is accepted in a considerably wide range from 0.07 to 0.11 for pure plumes. In this study, the entrainment coefficient of a pure plume is determined by analyzing the stratified interface formed between fresh water and a buoyant fluid in a confined space. The interface position is determined using digital image processing while conducting salt-water experiments. The displacement of the virtual origin of the real plume is added to the original heights of the confined space and stratified interface because the plume in the laboratory is from a source of finite area rather than from a point. The two virtual source position determination methods are compared; the one where the ratio of the displacement of the virtual origin to the nozzle diameter is related only to the source parameter Γ is selected for the theoretical analysis. The experimental data of the source parameter Γ and corresponding entrainment coefficients indicate that the α value of the pure plume is 0.09251 when using the interpolation method. This value is validated through displacement experiments on a pure plume created by supplying salt water through the nozzle in a laboratory. Further, the entrainment coefficient of a turbulent jet is determined based on the stratified interface behavior in a confined space; the experimental results support the speculation that the entrainment coefficient of the pure jet should be 0.057. The experimental data of the entrainment coefficient α plotted against parameter Γ in the available literature are compared with those estimated from semi-empirical equations with two asymptotic values suggested in this paper.

Graphical abstract

Article Highlights

-

Entrainment coefficient of a pure plume is determined by analyzing the interface between fresh water and buoyant fluid.

-

The interface position is determined using digital image processing while conducting salt-water experiments.

-

Two virtual source position determination methods are compared.

-

The α value of the pure plume is determined to be 0.09251 when using the interpolation method.

-

Experimental results support the speculation that the entrainment coefficient of the pure jet should be 0.057

source with virtual origin correction in a confined space showing the positions of the first front at two time instances. The horizontal dashed lines denote the positions of the first front. The cone-shaped and dashed lines indicate the plume boundary

source parameter Γ and the entrainment coefficient

source as a function of A*/H2

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

Abbreviations

- A * :

-

Effective opening area, m2

- A */H 2 :

-

Dimensionless effective area

- b :

-

Horizontal scale for a plume, m

- F :

-

Buoyant flux, m4/s3

- g :

-

Acceleration due to gravity, m/s2

- g’:

-

Reduced acceleration due to gravity, m/s2

- h :

-

Interface height, cm

- H :

-

Height of the model, cm

- h/H :

-

Dimensionless height

- M :

-

Momentum, m4/s2

- Q :

-

Volume flux, m3/s

- t :

-

Time, min

- U :

-

Vertical velocity in the environment, m/s

- w :

-

Vertical velocity in the plume, m/s

- z :

-

Vertical axis, g/cm3

- z * :

-

Dimensionless virtual source height

- z avs :

-

Height of virtual source point, cm

- α :

-

Entertainment coefficient

- Γ :

-

Source parameter

- ∆:

-

Density gradient, m/s2

- ξ:

-

Dimensionless height

- ρ :

-

Density of the plume, g/cm3

- ρ 0 :

-

Density of the environment, g/cm3

- ρ 1 :

-

Reference density, g/cm3

References

Steckler KD, Baum HR, Quintiere JG (1988) Salt water modeling of fire induced flows in multicompartment enclosures. Sym Comb 21(1):143–149. https://doi.org/10.1016/S0082-0784(88)80241-8

Wise NH, Hunt GR (2020) Buoyancy-driven unbalanced exchange flow through a horizontal opening. J Fluid Mech 888:1–23. https://doi.org/10.1017/jfm.2020.55

Partridge JL, Linden PF (2013) Validity of thermally-driven small-scale ventilated filling box models. Exp Fluids 54(11):1613. https://doi.org/10.1007/s00348-013-1613-4

Carlotti P, Hunt GR (2017) An entrainment model for lazy turbulent plumes. J Fluid Mech 811:682–700. https://doi.org/10.1017/jfm.2016.714

Kaye NB, Hunt GR (2009) An experimental study of large area source turbulent plumes. Int J Heat Fluid Fl 30(6):1099–1105. https://doi.org/10.1016/j.ijheatfluidflow.2009.05.001

Chenvidyakarn T, Woods AW (2008) On underfloor air-conditioning of a room containing a distributed heat source and a localised heat source. Energy Build 40(7):1220–1227. https://doi.org/10.1016/j.enbuild.2007.11.001

Craske J, Hughes GO (2019) On the robustness of emptying filling boxes to sudden changes in the wind. J Fluid Mech 868:R3. https://doi.org/10.1017/jfm.2019.199

Hunt GR, Linden PF (2004) Displacement and mixing ventilation driven by opposing wind and buoyancy. J Fluid Mech 527(527):27–55. https://doi.org/10.1017/s0022112004002575

Holford JM, Hunt GR (2003) Fundamental atrium design for natural ventilation. Build Environ 38(3):409–426. https://doi.org/10.1016/S0360-1323(02)00019-7

Kuesters AS, Woods AW (2012) On the competition between lateral convection and upward displacement in a multi-zone naturally ventilated space. J Fluid Mech 707:393–404. https://doi.org/10.1017/jfm.2012.287

Hunt GR, Bremer TSVD (2011) Classical plume theory: 1937–2010 and beyond. Ima J Appl Math 76(3):424–448. https://doi.org/10.1093/imamat/hxq056

Lin YJP, Linden PF (2002) Buoyancy-driven ventilation between two chambers. J Fluid Mech 463:293–312. https://doi.org/10.1017/s0022112002008832

Livermore SR, Woods AW (2007) Natural ventilation of a building with heating at multiple levels. Build Environ 42(3):1417–1430. https://doi.org/10.1016/j.buildenv.2005.12.014

Zel’Dovich YB (1937) The asymptotic laws of freely-ascending convective flows. Zh Eksp Teor Fiz 7:1463–1465

Priestley CHB, Ball FK (1955) Continuous convection from an isolated source of heat. Q J Roy Meteor Soc 81(348):144–157. https://doi.org/10.1002/qj.49708134803

Morton BR, Taylor G, Turner JS (1956) Turbulent gravitational convection from maintained and instantaneous sources. P Roy Soc Lond 234(1196):1–23. https://doi.org/10.1098/rspa.1956.0011

Debugne ALR, Hunt GR (2018) The influence of spanwise confinement on round fountains. J Fluid Mech 845:263–292. https://doi.org/10.1017/jfm.2018.194

Craske J, Maarten VR (2016) Generalised unsteady plume theory. J Fluid Mech 792(1013):1013–1052. https://doi.org/10.1017/jfm.2016.72

Jiang L, Creyssels M, Hunt G et al (2019) Control of light gas releases in ventilated tunnels. J Fluid Mech 872:515–531. https://doi.org/10.1017/jfm.2019.363

Loganathan R, Hunt G (2019) Analytical solutions for flow induced by a vertically distributed turbulent plume. Environ Fluid Mech. https://doi.org/10.1007/s10652-019-09659-z

Mingotti N, Cardoso SSS (2019) Mixing and reaction in turbulent plumes: the limits of slow and instantaneous chemical kinetics. J Fluid Mech 861:1–28. https://doi.org/10.1017/jfm.2018.840

Batchelor GK, Moffatt HK, Worster MG (2002) Perspectives in fluid dynamics. Cambridge University Press, Cambridge

Carazzo G, Kaminski E, Tait S (2006) The route to self-similarity in turbulent jets and plumes. J Fluid Mech 547(547):137–148. https://doi.org/10.1017/s002211200500683x

Linden PF, Lane-Serff GF, Smeed DA (1990) Emptying filling boxes: the fluid mechanics of natural ventilation. J Fluid Mech 212:309–335. https://doi.org/10.1017/s0022112090001987

Wang H, Wingkeung Law A (2002) Second-order integral model for a round turbulent buoyant jet. J Fluid Mech 459(459):397–428. https://doi.org/10.1017/s0022112002008157

Ezzamel A, Salizzoni P, Hunt GR (2015) Dynamical variability of axisymmetric buoyant plumes. J Fluid Mech 765:576–611. https://doi.org/10.1017/jfm.2014.694

Van Reeuwijk M, Salizzoni P, Hunt GR et al (2016) Turbulent transport and entrainment in jets and plumes: A DNS study. Phys Rev Fluids 1(7):1–22. https://doi.org/10.1103/physrevfluids.1.074301

Baines WD, Turner JS (1969) Turbulent buoyant convection from a source in a confined region. J Fluid Mech 37(4):51–80. https://doi.org/10.1017/s0022112069000413

Hunt GR, Kaye NG (2001) Virtual origin correction for lazy turbulent plumes. J Fluid Mech 435:377–396. https://doi.org/10.1017/s0022112001003871

List EJ, Imberger J (1973) Turbulent entrapment in buoyant jets and plumes. J Hydraul Div 99:1461–1474

Hunt GR, Linden PF (2001) Steady-state flows in an enclosure ventilated by buoyancy forces assisted by wind. J Fluid Mech 426(426):355–386. https://doi.org/10.1017/s0022112000002470

Dalziel SB (1993) Rayleigh-Taylor instability: experiments with image analysis. Dyn Atmos Oceans 20(1–2):127–153. https://doi.org/10.1016/0377-0265(93)90051-8

Kaye NB, Flynn MR, Cook MJ et al (2010) The role of diffusion on the interface thickness in a ventilated filling box. J Fluid Mech 652(1):195–205. https://doi.org/10.1017/S0022112010000881

Hill BJ (1972) Measurement of local entrainment rate in the initial region of axisymmetric turbulent air jets. J Fluid Mech 51(4):773–779. https://doi.org/10.1017/s0022112072001351

Ricou FP, Spalding DB (1961) Measurements of entrainment by axisymmetrical turbulent jets. J Fluid Mech 11(1):21–32. https://doi.org/10.1017/s0022112061000834

Rouse H, Yih CS, Humphreys HW (1952) Gravitational convection from a boundary source. Tellus 4(3):201–210. https://doi.org/10.3402/tellusa.v4i3.8688

List EJ (1982) Turbulent jets and plumes. Annu Rev Fluid Mech 14:189–212. https://doi.org/10.1146/annurev.fl.14.010182.001201

Craske J, van Reeuwijk M (2015) Energy dispersion in turbulent jets. Part 1. Direct simulation of steady and unsteady jets. J Fluid Mech 763:500–537. https://doi.org/10.1017/jfm.2014.640

George WK Jr, Alpert RL, Tamanini F (1977) Turbulence measurements in an axisymmetric buoyant plume. Int J Heat Mass Tran 20(11):1145–1154. https://doi.org/10.1016/0017-9310(77)90123-5

Fischer HB, List EJ, Koh RCY et al (1979) Mixing in inland and coastal waters. Academic Press, San Diego

van Reeuwijk M, Craske J (2015) Energy-consistent entrainment relations for jets and plumes. J Fluid Mech 782:333–355. https://doi.org/10.1017/jfm.2015.534

Albertson ML, Dai YB, Jensen RA et al (1950) Diffusion of submerged jets. T Am Soc Civil Eng 115(11):639–664

Baines WD (1975) Entrainment by a plume or jet at a density interface. J Fluid Mech 68(2):309–320. https://doi.org/10.1017/S0022112075000821

Lee HW (2003) Turbulent jets and plumes - a Lagrangian approach. Kluwer Academic Publishers, Massachusetts

Papanicolaou PN, List EJ (1988) Investigations of round vertical turbulent buoyant jets. J Fluid Mech 195:341–391. https://doi.org/10.1017/s0022112088002447

Funding

This research was supported by the National Natural Science Funds of China (No. 51666003).

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflicts of interests

The authors declare no conflicts of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix. Verification of the entrainment coefficient of the pure jet

Appendix. Verification of the entrainment coefficient of the pure jet

Based on Eqs. (12) and (13), the entrainment coefficient of a forced plume at a certain value of the parameter Γ depends on two asymptotic values: pure jet αj and pure plume αp. Fischer and List [40] and Carazzo et al. [23] presented comprehensive reviews of the entrainment coefficient of pure jets. The entrainment coefficient is in the range 0.045 < αj < 0.067 for pure jets with turbulent velocity described by Gaussian profiles. The measurements made by Albertson et al. [42] for round jets suggest a spread rate of 0.114 (implying αj = 0.057), and the general coefficient value has been adopted by Baines [43], List and Imberger [30], and Lee and Chu [44]. The experimental results obtained by Papanicolaou and List [45] show that the entrainment coefficient for a plume is close to 5/3 times the value for a jet, which can be verified from the measurement data obtained by Wang and Law [25] and the theoretical analysis results obtained by van Reeuwijk and Craske [41]. Once the entrainment coefficient of a pure plume is determined to be equal to 0.09251, the coefficient of a pure jet is 0.0555, which is very close to the value of 0.057. For the present purposes, αj = 0.057 will be used throughout the data analyses hereinafter.

As discussed in Sect. 4.4, the rate of advance of the stratified interface of the buoyant fluid in a confined space can be employed to determine the value of α for an axisymmetric plume. If the jet fluid is marked by a dye, the accurate measurement of the position of the stratified interface may also provide an effective method for determining the value of α for a pure jet.

Based on the Eulerian integral model [44], the axial velocity and jet width of an axisymmetric jet can be written in terms of the nozzle diameter D and source velocity u0 as

Note that M = M0, and \(M_{0} = \frac{\pi }{4}w_{0}^{2} D^{2}\) at the nozzle inlet.

Eqs. (3), (19), and (20) are combined at the stratification level in the confined space, and the velocity of the level dz0/dt = U is also used. Measuring from the time when the stratification is formed, the relationship between the position z0 and time t is integrated as

where

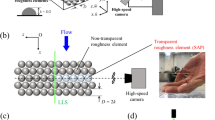

A smaller transparent tank (cross-sectional area of 17 cm × 18 cm and a depth of 33 cm) adopted in this group of experiments was similar to the plexiglass tank used in the experiment outlined in Sect. 4.2, and an opening with a diameter of 1.8 cm was also drilled on the side wall of the model, whose center is 30.5 cm above the bottom of the model box. The brine storage tank, source supply tank, and supply pipes for the brine solution were cleaned carefully before fresh water was mixed with a certain concentration of dye in the brine tank. In this group of experiments, the density of the fresh water solution containing the dye in the storage tank was 0.9958 g/cm3, which is the same as that of the fresh water of the environment, and the supply flow rate of the fresh water containing the dye was 60 ml/min. Two sheets of Perspex with a cross-sectional area of 16 cm × 16 cm were suspended horizontally in the plexiglass tank to prevent the bottom surface from creating disturbance in the tank, as shown in Fig.

12, while the round jet fluid moves to the lower boundary and the mixing fluid begins to ascend. The two sheets were all evenly perforated with several openings of diameter 0.8 cm at the periphery of the sheets. One was fixed 6 cm from the bottom of the model, with a hole of diameter 12 cm at the center, and the other at 15 cm from the bottom with a 9 cm hole at the center. Four groups of repeated experiments were performed under the same conditions.

There are two main differences in the ascending of the visible interfaces in the confined space with respect to the two sources (buoyant plume and pure jet). For a turbulent plume, the heavy fluid reaches the model bottom and spreads out to the side walls to produce a discontinuous interface. The horizontal interface is then pushed upward, and the marked layer can be easily observed. However, for a pure jet, no discrepancy in the density exists between the entrainment fluid and the environment fluid. Therefore, there is no mixing of the entrainment fluid in the horizontal level because of the same density, which leads to a visible interface of unequal height. Moreover, because of the lack of density gradient in the horizontal level, a remarkable vertical circulation is induced, and the environment fluid at the four corners on the lower part of the Plexiglas tank is not entrained by the jet fluid during the experiment.

To employ the approximate position of the first front of the buoyant fluid with time to determine the entrainment coefficient of a pure jet, we take the average ratio of the non-occupied volume by the dye solution to the whole box volume as 6.82%. For a flow from a circular orifice of diameter 5 mm, the virtual origin position of the real jet source can be deduced from Eq. (20). With αj = 0.057, the virtual origin correction for the jet position gives a constant value of zj = 2.19 cm in these experiments. By fitting a straight line through the corrected data ln(H + zj)/(z0 + zj) vs. kt, we determined the value of the jet entrainment coefficient, as shown in Fig.

13.

In the figure, the experiment data shows a linear relationship between ln(H/z0) and k·t, although the logarithm of ratio of height of the confined space to the stratification level measured in the middle of the experiment is a little higher than the data from fitting line. This discrepancy may be contributed to the stratification layer level harder to be observed in the space because of the same density between the entrainment fluid and the environment fluid. The slope of the fitted line yields αj = 0.056, which is slightly lower than the accepted value of 0.057. The source conditions used in the experiments and the corresponding entrainment coefficient of the pure jet are listed in Table

6. For an axisymmetric jet, the measurement of the interface formed by the dye solution in the confined space supports the fact that the entrainment coefficient of the pure jet should be 0.057.

Rights and permissions

About this article

Cite this article

Liu, Y., Li, X., Huang, L. et al. Determination of the entrainment coefficient of a pure plume using the salt-bath technique. Environ Fluid Mech 21, 1303–1332 (2021). https://doi.org/10.1007/s10652-021-09824-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10652-021-09824-3