Abstract

Manufacturing defects in ceramic matrix composites (CMCs), such as voids, microcracks, etc., significantly affect the damage events and strength of the materials. This study aims to reveal the effect of void defects on the failure behavior and tensile strength of a plain-woven C/SiC composite. The mesoscopic architectures of the C/SiC composites are tested by micro-computed tomography. Based on the μ-CT images of the material, finite element models (IB-FEM) of the C/SiC composite are established with different void volume fractions and different void geometry. The tensile strength and fracture features of the C/SiC composites are calculated by using the IB-FEM. The effects of void volume fraction and geometry on failure behaviors and tensile strength of the C/SiC composites are investigated and discussed. This study is of great significance for further understanding the influence of defects on the mechanical behavior of CMCs.

Similar content being viewed by others

Data Availability

We statement that all data related to this article will be made available at reasonable request.

References

Du, J.G., Zhang, H.Z., Geng, Y.M., Ming, W.Y., He, W.B., Ma, J., Cao, Y., Li, X.K., Liu, K.: A review on machining of carbon fiber reinforced ceramic matrix composites. Ceram. Int. 45, 18155–18166 (2019)

Wang, X.L., Gao, X.D., Zhang, Z.H., Cheng, L.S., Ma, H.P., Yang, W.M.: Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: A focused review. J. Eur. Ceram. Soc. 41(9), 4671–4688 (2021)

Su, F., Huang, P.F.: Microscopic Mechanism of the High-Temperature Strength Behaviour of a C/SiC Composite. Appl. Compos. Mater. 26, 1059–1071 (2019)

Naresh K., Khan K.A., Umer R., Cantwell W.J.: The use of X-ray computed tomography for design and process modeling of aerospace composites: A review Mater. Des. 190, 108533 (2020)

Galizia, P., Zoli, L., Sciti, D.: Impact of residual stress on thermal damage accumulation, and Young’s modulus of fiber-reinforced ultra-high temperature ceramics. Mater. Des. 160, 803–809 (2018)

Meyer, P., Waas, A.M.: FEM predictions of damage in continous fiber ceramic matrix composites under transverse tension using the crack band method. Acta Mater. 102, 292–303 (2016)

Zhang, S., Gao, X.G., Song, Y.D.: In Situ Strength Model for Continuous Fibers and Multi-Scale Modeling the Fracture of C/SiC Composites. Appl. Compos. Mater. 26, 357–370 (2019)

Ai, S.G., Fu, H.L., He, R.J., Pei, Y.M.: Multi-scale modeling of thermal expansion coefficients of C/C composites at high temperature. Mater. Des. 82, 181–188 (2015)

Chen, X.H., Sun, Z.G., Chen, P., Song, Y.D., Niu, X.M.: Modeling Thermal Expansion Behavior of 2.5 D C/SiC Composites in Air Oxidizing Environments between 400 °C and 800 °C. Appl. Compos. Mater. 27, 861–875 (2020)

Zhao, Y.N., Chen, Y.F., He, C.W., Ai, S.G., Fang, D.N.: A damage-induced short-circuit diffusion model applied to the oxidation calculation of ceramic matrix composites (CMCs) Compos. A: Appl. Sci. Manuf. 127, 105621 (2019)

Gao, X.G., Han, X., Song, Y.D.: X-ray computed tomography based microstructure reconstruction and numerical estimation of thermal conductivity of 2.5D ceramic matrix composite. Ceram.Int. 43, 9790–9797(2017)

Daggumati, S., Sharma, A., Kasera, A., Upadhyay, N.: Failure Analysis of Unidirectional Ceramic Matrix Composite Lamina and Cross-Ply Laminate under Fiber Direction Uniaxial Tensile Load: Cohesive Zone Modeling and Brittle Fracture Mechanics Approach. J. of Materi Eng and Perform 29, 2049–2060 (2020)

Chen, X.H., Sun, Z.G., Sun, J.F., Song, Y.D.: Simulation of Degraded Properties of 2D plain Woven C/ SiC Composites under Preloading Oxidation Atmosphere. Appl. Compos. Mater. 24, 1287–1307 (2017)

Wang, F.Y., Cheng, L.F., Liang, S.H.: Effects of Pore on Thermal Diffusivity and Thermal Radiation Properties of C/SiC Composites at High Temperatures. Appl. Compos. Mater. 26, 1411–1422 (2019)

Chen, Y.F., Zhao, Y.N., Ai, S.G., He, C.W., Tao, Y., Yang, Y.Z., Fang, D.N.: A constitutive model for elastoplastic-damage coupling effect of unidirectional fiber-reinforced polymer matrix composites. Compos. A: Appl. Sci. Manuf. 130, 105736 (2020)

Kumar, R.S.: Effects of randomly distributed defects on Mode-I interlaminar fracture of composite materials. Eng Fract Mech. 248, 107699 (2021)

Hausherr, J.M., Wagner, L., Gorywod, M.: Fabrication of artificial defects and their effect on the mechanical properties of C/C-SiC. J. Eur. Ceram. Soc. 40, 636–641 (2020)

Dong, H.N., Gao, X.G., Song, Y.D.: Prediction model of matrix crack density in ceramic matrix composites under arbitrary matrix stress distribution. Mech. Adv. Mater. Struc. (2020)

Xiao, J., Liu, N., Lua, J., Saathoff, C., Seneviratne, W.: Data-Driven and Reduced-Order Modeling of Composite Drilling. AIAA SciTech Forum. 1859 (2020)

Liu, N., Jeffers, A.E.: Rational Bézier triangles for the analysis of is geometric higher-order gradient damage models, in: 13th World Congress on Computational Mechanics (WCCM XIII) and 2nd Pan American Congress on Computational Mechanics (PANACM II), New York City, NY, USA, July 22–27, (2018)

Liu, N., Jeffers, A.E.: Feature-preserving rational Bézier triangles for isogeometric analysis of higher-order gradient damage models. Comput. Methods Appl. Mech. Engrg. 357, 112585 (2019)

Liu, N., Xiao, J., Cui, X.D., Liu, P., Lua, J.: A Continuum Damage Mechanics (CDM) Modeling Approach for Prediction of Fatigue Failure of Metallic Bolted Joints. AIAA SciTech Forum. 0237 (2019)

Liu, N., Cui, X.D., Xiao, J., Lua, J., Phan, N.: A simplified continuum damage mechanics based modeling strategy for cumulative fatigue damage assessment of metallic bolted joints. Int. J. Fatigue. 131 105302 ,(2020)

Ahmadian, H., Liang, B., Soghrati, S.: Analyzing the impact of microstructural defects on the failure response of ceramic fiber reinforced aluminum composites. Int. J. Solids. Struc. 97–98, 43–55 (2016)

Gowayed, Y., Ojard, G., Prevost, E., Santhosh, U., Jefferson, G.: Defects in ceramic matrix composites and their impact on elastic properties. Compos. B: Eng. 55, 167–175 (2013)

Xu, J., Lu, X.F., Zhu, X.L.: Effect of Random Void Defects on the Mechanical Behavior of C/C Braided Composites. Adv. Eng. Mater. 20, 1701164 (2018)

Xu, Y.J., Ren, S.X., Zhang, W.L., Wu, Z.Q., Gong, W.R., Li, H.B.: Study of thermal buckling behavior of plain woven C/SiC composite plate using digital image correlation technique and finite element simulation. Thin Wall Struct. 131, 385–392 (2018)

Liu, N., Jeffers, A.E.: Isogeometric analysis of laminated composite and functionally graded sandwich plates based on a layerwise displacement theory. Compos. Struct. 176, 143–153 (2017)

Liu, N., Jeffers, A.E.: Adaptive isogeometric analysis in structural frames using a layer-based discretization to model spread of plasticity. Comput Struct. 196, 1–11 (2018)

Liu, N., Ren, X., Lua, J.: An isogeometric continuum shell element for modeling the nonlinear response of functionally graded material structures. Compos. Struct. 237, 111893 (2020)

Wang, L., Zhang, W., Li, H.B., Hou, C.T., Ren, F.: 3D In-Situ Characterizations of Damage Evolution in C/SiC Composite under Monotonic Tensile Loading by Using X-Ray Computed Tomography. Appl. Compos. Mater. 27, 119–130 (2020)

Wang, F., Pirzada, T.J., Liu, R.J., Wang, Y.F., Zhang, C.R., Marrow, T.J.: Microstructure Characterization by X-Ray Computed Tomography of C/C-SiC Ceramic Composites Fabricated with Different Carbon Fiber Architectures. Appl. Compos. Mater. 26, 1247–1260 (2019)

Huang, W.K., Zhang, X.N., Yin, Y.M.: An Image-Based Finite Element Approach for Simulating Viscoelastic Response of Asphalt Mixture. Adv. Mater. Sci. Eng. 7428623 (2016)

Zhu, X.L., Ai, S.G., Fang, D.N., Liu, B., Lu, X.F.: A novel modeling approach of aluminum foam based on MATLAB image processing. Comp. Mater. Sci. 82, 451–456 (2014)

Rossol, M.N., Fast, T., Marshall, D.B., Cox, B.N., Zok, F.W.: Characterizing In-Plane Geometrical Variability in Textile Ceramic Composites. J. Am. Ceram. Soc. 98, 205–213 (2015)

Li, Y., Hao, J., Wang, Z.G., Guan, Z.Z., Liu, J.L., Jin, C.Y.: Influence of ultra-high-rise pumping on microstructure and multi-scale mechanical properties of concrete based on X-ray CT and 3D mesoscopic numerical simulation. Constr Build Mater. 267, 120980 (2021)

Rinaldi, R.G., Blacklock, M., Bale, H., Begley, M.R., Cox, B.N.: Generating virtual textile composite specimens using statistical data from micro-computed tomography: 3D tow representations. J. Mech. Phys. Solids. 60, 451–470 (2012)

Bale, H., Blacklock, M., Begley, M.R., Marshall, D.B., Cox, B.N., Ritchie, R.O.: Characterizing three-dimensional textile ceramic composites using synchrotron x-ray micro-computed-tomography. J. Am. Ceram. Soc. 95, 392–402 (2012)

Blacklock, M., Shaw, J.H., Zok, F.W., Cox, B.N.: Virtual specimens for analyzing strain distributions in textile ceramic composites. Compos. A: Appl. Sci. Manuf. 85, 40–51 (2016)

Ghaedsharaf, M., Brunel, J.E., Lebel, L.L.: Fiber-level numerical simulation of biaxial braids for mesoscopic morphology prediction validated by X-ray computed tomography scan. Compos. B. Eng. 218, 108938 (2021)

Sencu, R.M., Yang, Z., Wang, Y.C., Withers, P.J., Rau, C., Parson, A., Soutis, C.: Generation of micro-scale finite element models from synchrotron X-ray CT images for multidirectional carbon fibre reinforced composites. Compos. A: Appl. Sci. Manuf. 91, 85–95 (2016)

Mazars, V., Caty, O., Couégnat, G., Bouterf, A., Roux, S., Denneulin, S., Pailhès, J., Vignoles, C.L.: Damage investigation and modeling of 3D woven ceramic matrix composites from X-ray tomography in-situ tensile tests. Acta Mater. 140, 130–139 (2017)

Gao, Y.T., Wang, Y.D., Yang, X.M., Liu, M., Huai, P., Zhou, X.T.: Synchrotron X-ray tomographic characterization of CVI engineered 2D-woven and 3D-braided SiCf/SiC composites. Ceram. Int. 42, 17137–21714 (2016)

Ai, S.G., Fang, D.N., He, R.J., Pei, Y.M.: Effect of manufacturing defects on mechanical properties and failure features of 3D orthogonal woven C/C composites. Compos. B: Eng. 71, 113–121 (2015)

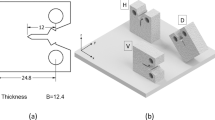

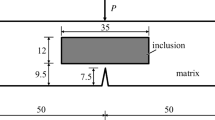

Ai, S.G., Song, W.L., Chen, Y.F.: Stress field and damage evolution in C/SiC woven composites: Image-based finite element analysis and in situ X-ray computed tomography tests. J. Eur. Ceram. Soc. 41, 2323–2334 (2021)

Ge, L., Li, H.M., Zhong, J.H., Zhang, C., Fang, D.N.: Micro-CT based trans-scale damage analysis of 3D braided composites with pore defects. Compos Sci Technol. 211, 108830 (2021)

Yang, H., Wang, W.F., Shang, J.C., Wang, P.D., Lei, H.S., Chen, H.S., Fang D.N.: Segmentation of computed tomography images and high-precision reconstruction of rubber composite structure based on deep learning. Compos Sci Technol. 213, 108875 (2021)

Linde, P., Pleitner, J., Boer, H.D., Carmone, C.: Modelling and Simulation of Fibre Metal Laminates. In ABAQUS Users Conference. (2004)

Christos, C.C.: Mechanics of composite materials: past, present, and future. NASA technical memorandum 100793, in 21st Annual Meeting of the Society for Engineering Science, Blacksburg, Virginia, October 15–17 (1984)

Sauder, C., Lamon, J., Pailler, R.: Thermomechanical properties of carbon fibres at high temperatures (up to 2000 °C). Compos. Sci. Technol. 62, 499–504 (2002)

Fang, G.D., Liang, L., Wang, B.L.: Progressive damage and nonlinear analysis of 3D four-directional braided composites under unidirectional tension. Compos. Struct. 89, 126–133 (2009)

ABAQUS 6.13 User’s Manual. ABAQUS Inc, 2013; Pawtucket, RI, USA

Snead, L.L., Nozawa, T., Katoh, Y., Byun, T.S., Kondo, S., Petti, D.A.: Handbook of SiC properties for fuel performance modeling. J. Nucl. Mater. 371, 329–377 (2007)

Cockeram, B.V.: Flexural Strength and Shear Strength of Silicon Carbide to Silicon Carbide Joints Fabricated by a Molybdenum Diffusion Bonding Technique. J. Am. Ceram. Soc. 88, 1892–1899 (2005)

Acknowledgements

Financial supports from the National Natural Science Foundations of China (No. 11872102, 52032003) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Q., Chen, Y., Chen, Y. et al. Effects of Void Defects on Fracture Features and Tensile Strength of C/SiC Composites: an Image-based FEM Study. Appl Compos Mater 29, 1021–1039 (2022). https://doi.org/10.1007/s10443-021-10002-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-021-10002-3