Abstract

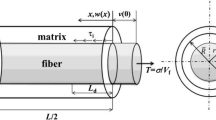

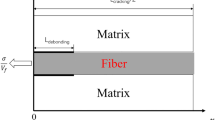

The current research work presents the computational micromechanical analysis of the room temperature tensile failure behavior of unidirectional (UD) and cross-ply (0/90) ceramic matrix composites (CMCs). For computational micromechanical analysis, three-dimensional (3D) representative volume element (RVE) and multi-fiber multilayer RVE (M2 RVE) models are generated that are representative of the lamina and the laminate under investigation. The RVE and M2 RVE models are generated by replicating the fiber distribution, and the placement of the fibers observed in a microscopic image of an actual CMC laminate. The generated RVE models consist of the discrete representation of individual constituent phases of the CMC such as fibers, interphase, matrix, and the fiber–interphase interface region. Under the applied external tensile load, the fiber–interphase interface interactions are modeled using the cohesive elements that follow the bilinear traction separation law. The matrix, fiber, and interphase materials failure behavior is captured using a brittle cracking model. In order to validate the proposed numerical methodology, the predicted average stress–strain curve at the UD laminate level is compared to the experimental stress–strain curve reported in the literature. In addition, the observed different phases in the predicted stress–strain curve are validated with the literature data. Using the proposed numerical methodology, a detailed local stress–strain and damage analysis leads to an observation that the so-called ductile stress–strain behavior (kink in the stress–strain curve) of a CMC UD laminate under uniaxial fiber direction tensile loads is mainly caused by the matrix damage initiation. Apart from the SiC material properties such as strength and fracture energy, it is also observed that the RVE size influences the average strength and failure strain predictions using computational micromechanics.

Similar content being viewed by others

References

S. Daggumati, A. Sharma, and Y.S. Pydi, Micromechanical FE Analysis of SiCf/SiC Composite with BN Interface, Silicon, 2020, 12(2), p 245–261. https://doi.org/10.1007/s12633-019-00119-3

R. Naslain, Design, Preparation and Properties of Non-oxide CMCs for Application in Engines and Nuclear Reactors: An Overview, Compos. Sci. Technol., 2004, 64(2), p 155–170. https://doi.org/10.1016/S0266-3538(03)00230-6

M. Grujicic, J.S. Snipes, R. Galgalikar, R. Yavari, V. Avuthu, and S. Ramaswami, Multi-length-scale Derivation of the Room-Temperature Material Constitutive Model for SiC/SiC Ceramic-Matrix Composites, Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl., 2015, 231(5), p 443–462. https://doi.org/10.1177/1464420715600002

D.G. Dunn, The effect of fiber volume fraction in HiperComp® SiC-SiC composites. Ph.D Dissertation, Alfred Univ., New York (2010).

A.G. Evans, Ceramics and Ceramic Composites as High-Temperature Structural Materials: Challenges and Opportunities, Philos. Trans. R. Soc. Lond. Ser. A Phys. Eng. Sci., 1995, 351(1697), p 511–527. https://doi.org/10.1098/rsta.1995.0050

V. Bheemreddy, K. Chandrashekhara, L.R. Dharani, and G.E. Hilmas, Computational Study of Micromechanical Damage Behavior in Continuous Fiber-Reinforced Ceramic Composites, J. Mater. Sci., 2016, 51(18), p 8610–8624. https://doi.org/10.1007/s10853-016-0120-4

A.G. Evans and F.W. Zok, The Physics and Mechanics of Fibre-Reinforced Brittle Matrix Composites, J. Mater. Sci., 1994, 29(15), p 3857–3896. https://doi.org/10.1007/BF00355946

K.M. Sevener, J.M. Tracy, Z. Chen, J.D. Kiser, and S. Daly, Crack Opening Behavior in Ceramic Matrix Composites, J. Am. Ceram. Soc., 2017, 100(10), p 4734–4747. https://doi.org/10.1111/jace.14976

J.M. Tracy, Multi-scale Investigation of Damage Mechanisms in SiC/SiC Ceramic Matrix Composites, Univ of Michigan, Ann Arbor, 2014

B.A. Bednarcyk, S.K. Mital, E.J. Pineda, and S.M. Arnold, Multiscale Modeling of Ceramic Matrix Composites, in 56th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, 2015, p 1191. https://doi.org/10.2514/6.2015-1191.

S. Mital, R. Goldberg, and P. Bonacuse, Modeling of Damage Initiation and Progression in a SiC/SiC Woven Ceramic Matrix Composite,” in 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, 2012, p 1–14. https://doi.org/10.2514/6.2012-1652.

T.J. Vaughan and C.T. McCarthy, Micromechanical Modelling of the Transverse Damage Behaviour in Fibre Reinforced Composites, Compos. Sci. Technol., 2011, 71(3), p 388–396. https://doi.org/10.1016/j.compscitech.2010.12.006

C. McCarthy and T. Vaughan, Micromechanical Failure Analysis of Advanced Composite Materials, in Numerical Modelling of Failure in Advanced Composite Materials, Elsevier Ltd., 2015, p 379–409.

C. González and J. LLorca, Mechanical Behavior of Unidirectional Fiber-Reinforced Polymers under Transverse Compression: Microscopic Mechanisms and Modeling, Compos. Sci. Technol., 2007, 67(13), p 2795–2806. https://doi.org/10.1016/j.compscitech.2007.02.001

L. Yang, Y. Yan, Y. Liu, and Z. Ran, Microscopic Failure Mechanisms of Fiber-Reinforced Polymer Composites under Transverse Tension and Compression, Compos. Sci. Technol., 2012, 72(15), p 1818–1825. https://doi.org/10.1016/j.compscitech.2012.08.001

L. Yang, Z. Wu, Y. Cao, and Y. Yan, Micromechanical Modelling and Simulation of Unidirectional Fibre-Reinforced Composite under Shear Loading, J. Reinf. Plast. Compos., 2014, 34(1), p 72–83. https://doi.org/10.1177/0731684414562873

M. Romanowicz, A Numerical Approach for Predicting the Failure Locus of Fiber Reinforced Composites under Combined Transverse Compression and Axial Tension, Comput. Mater. Sci., 2012, 51(1), p 7–12. https://doi.org/10.1016/j.commatsci.2011.07.039

M. Braginsky and C.P. Przybyla, Simulation of Crack Propagation/Deflection in Ceramic Matrix Continuous Fiber Reinforced Composites with Weak Interphase via the Extended Finite Element Method, Compos. Struct., 2016, 136, p 538–545. https://doi.org/10.1016/j.compstruct.2015.10.038

S.K. Mital, B.A. Bednarcyk, S.M. Arnold, and J. Lang, Modeling of Melt-Infiltrated SiC/SiC Composite Properties, Technical Report. NASA/TM-2009–215806, E-17069, NASA Glenn Research Center, Cleveland, OH, United States, 2009.

C. Chateau, L. Gélébart, M. Bornert, and J. Crépin, Micromechanical Modeling of the Elastic Behavior of Unidirectional CVI, SiC/SiC Composites, Int. J. Solids Struct., 2015, 58, p 322–334. https://doi.org/10.1016/j.ijsolstr.2014.11.020

E. Totry, C. González, and J. LLorca, Prediction of the Failure Locus of C/PEEK Composites under Transverse Compression and Longitudinal Shear Through Computational Micromechanics, Compos. Sci. Technol., 2008, 68(15–16), p 3128–3136. https://doi.org/10.1016/j.compscitech.2008.07.011

D. Garoz et al., Consistent Application of Periodic Boundary Conditions in Implicit and Explicit Finite Element Simulations of Damage in Composites, Compos. Part B, 2019, 168, p 254–266. https://doi.org/10.1016/j.compositesb.2018.12.023

ABAQUS, Analysis User’s Manual. Version 6.10,” Dassault Systemes Simulia, Inc., 2010.

J.G. Rots, Computational Modeling of Concrete Fracture, Ph.D Dissertation, Delft Univ. of Tech., Netherlands, 1988.

A. Hillerborg, M. Modéer, and P.E. Petersson, Analysis of Crack Formation and Crack Growth in Concrete by Means of Fracture Mechanics and Finite Elements, Cem. Concr. Res., 1976, 6(6), p 773–781. https://doi.org/10.1016/0008-8846(76)90007-7

Z.P. Bazant and B.H. Oh, Crack Band Theory for Fracture of Concrete, Matér. Constr., 1983, 16(3), p 155–177. https://doi.org/10.1007/BF02486267

J.G. Rots and J. Blaauwendraad, Crack Models for Concrete: Discrete or Smeared? Fixed, Multi-directional or Rotating?, Heron, 1989, 34(1), p 3–59

G. Corman and K. Luthra, Melt Infiltrated Ceramic Composites (Hipercomp) For Gas Turbine Engine Applications, in Continuous Fiber Ceramic Composites Program Phase II Final Report for the Period May 1994–Sept. 2005, 2006, p 31–53.

C. Chateau, L. Gélébart, M. Bornert, J. Crépin, D. Caldemaison, and C. Sauder, Modeling of Damage in Unidirectional Ceramic Matrix Composites and Multi-scale Experimental Validation on Third Generation SiC/SiC Minicomposites, J. Mech. Phys. Solids, 2014, 63, p 298–319. https://doi.org/10.1016/j.jmps.2013.09.001

D. Zhang and D.R. Hayhurst, Stress–strain and Fracture Behaviour of 0°/90° and Plain Weave Ceramic Matrix Composites from Tow Multi-axial Properties, Int. J. Solids Struct., 2010, 47(21), p 2958–2969. https://doi.org/10.1016/j.ijsolstr.2010.06.023

W.A. Curtin, Theory of Mechanical Properties of Ceramic-Matrix Composites, J. Am. Ceram. Soc., 1991, 74(11), p 2837–2845. https://doi.org/10.1111/j.1151-2916.1991.tb06852.x

W.A. Curtin, B.K. Ahn, and N. Takeda, Modeling Brittle and Tough Stress–strain Behavior in Unidirectional Ceramic Matrix Composites, Acta Mater., 1998, 46(10), p 3409–3420. https://doi.org/10.1016/S1359-6454(98)00041-X

J.A. Coppola and R.C. Bradt, Measurement of Fracture Surface Energy of SiC, J. Am. Ceram. Soc., 1972, 55(9), p 455–460. https://doi.org/10.1111/j.1151-2916.1972.tb11339.x

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Daggumati, S., Sharma, A., Kasera, A. et al. Failure Analysis of Unidirectional Ceramic Matrix Composite Lamina and Cross-Ply Laminate under Fiber Direction Uniaxial Tensile Load: Cohesive Zone Modeling and Brittle Fracture Mechanics Approach. J. of Materi Eng and Perform 29, 2049–2060 (2020). https://doi.org/10.1007/s11665-020-04724-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04724-x