Abstract

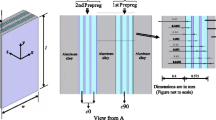

Fiber metal laminates (FMLs) are typical multilayer composites including metallic foils and fiber reinforced polymers. These are considered as the attractive skin materials for lightweight vehicle, especially GLARE laminates for aircraft fuselages. The open-hole tensile behavior and progressive damage of GLARE laminate are studied experimentally and numerically. A combined progressive failure model with strain-based damage evolution laws are imposed on the composite layer based on the subroutine Abaqus-VUMAT. The cohesive zone model and equivalent plastic strain criterion with isotropic hardening is respectively employed to describe the interlaminar and metal layer damage. The effects on the geometry characteristics of open-hole are discussed, exploring the variation of residual strength, damage evolution process and damage affected zone. The two fracture modes and delamination failure are observed, all numerical results show good agreement with experiment obtained. The damage evolution of fiber both gradually vary from “butterfly” to “funnel” pattern for circluar and square open-hole. However, the different evolution emerges for matrix damage. Compared with circular one, the square open-hole can lead to more fiber damage than matrix one. The transition fillet can effectively disperse stress concentration, improving the residual strength of GLARE with square open-hole. The 45° off-axis is the optimal design of square open-hole to fully activate the reinforcement effect of fiber. All suggest the open-hole design is important to guarantee the application security for GLARE plate-like structure.

Similar content being viewed by others

Availability of Data and Material

All data generated or analyzed during this study are included in this published article. The VUMAT codes cannot be shared at this time as the data also forms part of an ongoing study.

References

Vlot, A.: Glare: history of the development of a new aircraft material. Kluwer Academic Publishers, Dordrecht, The Netherlands. (2001)

Gunnink, J.W., Vlot, A., de Vries, T.J., van de Hoeven, W.: Glare Technology Development 1997–2000. Appl. Compos. Mater. 9, 201–219 (2002). https://doi.org/10.1023/A:1016006314630

Roebroeks, G.H.J.J.: Fiber-metal laminates: Recent developments and applications. Int. J. Fatigue. 16, 33–42 (1994). https://doi.org/10.1016/0142-1123(94)90443-X

Alderliesten, R.C., Homan, J.J.: Fatigue and damage tolerance issues of Glare in aircraft structures. Int. J. Fatigue 28, 1116–1123 (2006). https://doi.org/10.1016/j.ijfatigue.2006.02.015

Morinière, F.D., Alderliesten, R.C., Tooski, Y.M., Benedictus, R.: Damage evolution in GLARE fibre-metal laminate under repeated low-velocity impact tests. Cent. Eur. J. Eng. 2, 603–611 (2012). https://doi.org/10.2478/s13531-012-0019-z

Chai, G.B., Manikandan, P.: Low velocity impact response of fiber-metal laminates-A review. Compos. Struct. 107, 363–381 (2014). https://doi.org/10.1016/j.compstruct.2013.08.003

Ucan, H., Apmann, H., Graßl, G., Krombholz, C., Fortkamp, K., Nieberl, D., Schmick, F., Nguyen, C., Akin, D.: Production technologies for lightweight structures made from fiber-metal laminates in aircraft fuselages. Aeronaut. J. 10, 479–489 (2019). https://doi.org/10.1007/s13272-018-0330-3

Woerden, H.J.M., Sinke, J., Hooijmeijer, P.A.: Maintenance of Glare structures and Glare as riveted or bonded repair material. Appl. Compos. Mater. 10, 307–329 (2003). https://doi.org/10.1023/A:1025593314780

Chang, F.K., Lessard, L.B.: Damage tolerance of laminated composites containing an open hole and subjected to compressive loadings. I: Analysis. J. Compos. Mater. 25, 2–43 (1991). https://doi.org/10.1177/002199839102500101

Liu, X., Wang, G.: Progressive failure analysis of bonded composite repairs. Compos. Struct. 81, 331–340 (2007). https://doi.org/10.1016/j.compstruct.2006.08.024

Du, D.D., Hu, Y.B., Li, H.G., Liu, C., Tao, J.: Open-hole tensile progressive damage and failure prediction of carbon fiber-reinforced PEEK-titanium laminates. Compos. Part B-Eng. 91, 65–74 (2016). https://doi.org/10.1016/j.compositesb.2015.12.049

Soltani, P., Keikhosravy, M., Oskouei, R.H., Soutis, C.: Studying the tensile behaviour of GLARE laminates: a finite element modelling approach. Appl. Compos. Mater. 18, 271–282 (2011). https://doi.org/10.1007/s10443-010-9155-x

Xie, B., Gao, L., Jiang, S., Zhang, S.D., Ran, X.: Notched tensile response and damage mechanism of the GLARE laminate. J. Compos. Mater. 54, 3037–3046 (2020). https://doi.org/10.1177/0021998320907963

Sadeghpour, E., Sadighi, M., Dariushi, S.: An investigation on blunt notch behavior of fiber metal laminates containing notch with different shapes. J. Reinf. Plast. Comp. 32, 1143–1152 (2013). https://doi.org/10.1177/0731684413484817

Su, Z., Xie, C., Tang, Y.: Stress distribution analysis and optimization for composite laminate containing hole of different shapes. Aerosp. Sci. Technol. 76, 466–470 (2018). https://doi.org/10.1016/j.ast.2018.01.046

Wu, G., Tan, Y., Yang, J.M.: Evaluation of residual strength of notched fiber metal laminates. Mater. Sci. Eng. A 457, 338–349 (2007). https://doi.org/10.1016/j.msea.2006.12.135

Kawai, M., Arai, Y.: Off-axis notched strength of fiber-metal laminates and a formula for predicting anisotropic size effect. Compos. Part A-Appl. S. 40, 1900–1910 (2009). https://doi.org/10.1016/j.compositesa.2009.07.014

Zhang, J., Wang, Y., Zhang, J., Zhou, Z., Fang, G., Zhao, Y., Zu, S.M.: Characterizing the off-axis dependence of failure mechanism in notched fiber metal laminates. Compos. Struct. 185, 148–160 (2018). https://doi.org/10.1016/j.compstruct.2017.11.016

ASTM D3039/D3039M-08, Standard test method for tensile properties of polymer matrix composite materials. West Conshohocken, PA 19428–2959, United States.

Hashin, Z.: Fatigue failure criteria for unidirectional fiber composites. J. Appl. Mech. 48, 846–852 (1981). https://doi.org/10.1115/1.3153664

Yeh, H.Y., Kim, C.H.: The Yeh-stratton criterion for composite materials. J. Compos. Mater. 28, 926–939 (1994). https://doi.org/10.1177/002199839402801003

Huang, C.H., Lee, Y.J.: Experiments and simulation of the static contact crush of composite laminated laminates. Compos. Struct. 61, 265–270 (2003). https://doi.org/10.1016/S0263-8223(02)00047-8

Benzeggagh, M.L., Kenane, M.: Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos. Sci. Technol. 56, 439–449 (1996). https://doi.org/10.1016/0266-3538(96)00005-X

Sugiman, S., Crocombe, A.D., Katnam, K.B.: Investigating the static response of hybrid fiber-metal laminate doublers loaded in tension. Compos. Part B-Eng. 42, 1867–1886 (2010). https://doi.org/10.1016/j.compositesb.2011.06.013

Chen, J.F., Morozov, E.V., Shankar, K.: Progressive failure analysis of perforated aluminium/CFRP fiber metal laminates using a combined elastoplastic damage model and including delamination effects. Compos. Struct. 114, 64–79 (2014). https://doi.org/10.1016/j.compstruct.2014.03.046

Zhou, Y.H., Nezhad, H.Y., Hou, C., Wan, X.P., McCarthy, C.T., McCarthy, M.A.: A three dimensional implicit finite element damage model and its application to single-lap multi-bolt composite joints with variable clearance. Compos. Struct. 131, 1060–1072 (2015). https://doi.org/10.1016/j.compstruct.2015.06.073

Frizzell, R.M., Mccarthy, C.T., Mccarthy, M.A.: Simulating damage and delamination in fibre metal laminate joints using a three-dimensional damage model with cohesive elements and damage regularisation. Compos. Sci. Technol. 71, 1225–1235 (2011). https://doi.org/10.1016/j.compscitech.2011.04.006

O’Higgins, R.M., Padhi, G.S., McCarthy, M.A., McCarthy, C.T.: Experimental and numerical study of the open-hole tensile strength of carbon/epoxy composites. Mech. Compos. Mater. 40, 269–278 (2004). https://doi.org/10.1023/B:MOCM.0000039744.98869.0d

Shin, D.K., Kim, H.C., Lee, J.J.: Numerical analysis of the damage behavior of an aluminum/CFRP hybrid beam under three-point bending. Compos. Part B-Eng. 56, 397–407 (2014). https://doi.org/10.1016/j.compositesb.2013.08.030

Nardi, D., Abouhamzeh, M., Leonard, R., Sinke, J.: Detection and evaluation of pre-preg gaps and overlaps in Glare laminates. Appl. Compos. Mater. 25, 1491–1507 (2018). https://doi.org/10.1007/s10443-018-9679-z

Stijlen, S., Bakker, M.: Ultrasonic nondestructive inspection of interface defects in anisotropic fiber-metal-laminates. J. Acoust. Soc. Am. 116, 2591–2594 (2004). https://doi.org/10.1121/1.4785336

Sreeshan, K., Dinesh, R., Renji, K.: Nondestructive inspection of aerospace composite laminate using thermal image processing. SN Appl. Sci. 2, 1–14 (2020). https://doi.org/10.1007/s42452-020-03619-9

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 11502031, No. 51874043), Capital Construction Project within the Provincial Budget 2019 of Jilin Province Development and Reform Commission of China (No. 2019C046-6).

Author information

Authors and Affiliations

Contributions

Liang Gao: Conceptualization, Methodology, Writing-Review & Editing, Project administration. Shuai Jiang: Software, Data curation, Visualization, Writing-Original draft preparation. Botao Xie: Investigation, Visualization. Kai Li: Resources, Validation. Chen Wu: Data curation, Writing-Review & Editing. All authors read and approve the final manuscript.

Corresponding authors

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, S., Gao, L., Xie, B. et al. Open-Hole Tensile Behavior and Progressive Damage of Hybrid Fiber Metal Laminates. Appl Compos Mater 29, 547–563 (2022). https://doi.org/10.1007/s10443-021-09981-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-021-09981-0