Abstract

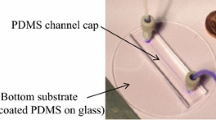

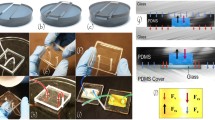

Reversibly assembled microfluidic devices are dismountable and reusable, which is useful for a number of applications such as micro- and nano-device fabrication, surface functionalization, complex cell patterning, and other biological analysis by means of spatial–temporal pattern. However, reversible microfluidic devices fabricated with current standard procedures can only be used for low-pressure applications. Assembling technology based on glass–PDMS–glass sandwich configuration provides an alternative sealing method for reversible microfluidic devices, which can drastically increase the sealing strength of reversibly adhered devices. The improvement mechanism of sealing properties of microfluidic devices based on the sandwich technique has not been fully characterized, hindering further improvement and broad use of this technique. Here, we characterize, for the first time, the effect of various parameters on the sealing strength of reversible PDMS/glass hybrid microfluidic devices, including contact area, PDMS thickness, assembling mode, and external force. To further improve the reversible sealing of glass–PDMS–glass microfluidic devices, we propose a new scheme which exploits mechanical clamping elements to reinforce the sealing strength of glass–PDMS–glass sandwich structures. Using our scheme, the glass–PDMS–glass microchips can survive a pressure up to 400 kPa, which is comparable to the irreversibly bonded PDMS microdevices. We believe that this bonding method may find use in lab-on-a-chip devices, particularly in active high-pressure-driven microfluidic devices.

Similar content being viewed by others

References

Atencia J, Beebe DJ (2004) Controlled microfluidic interfaces. Nature 437(7059):648–655

Butt H-J, Kappl M (2010) Surface and interfacial forces. Wiley-VCH, New York

Choi KM, Rogers JA (2003) A photocurable poly (dimethylsiloxane) chemistry designed for soft lithographic molding and printing in the nanometer regime. J Am Chem Soc 125(14):4060–4061

Crozatier C, Berre ML, Chen Y (2006) Multi-colour micro-contact printing based on microfluidic network inking. Microelectron Eng 83(4):910–913

Inglis DW (2010) A method for reducing pressure-induced deformation in silicone microfluidics. Biomicrofluidics 4(2):026504

Kane RS, Takayama S, Ostuni E, Ingber DE, Whitesides GM (1999) Patterning proteins and cells using soft lithography. Biomaterials 20(23):2363–2376

Le Berre M, Crozatier C, Velve Casquillas G, Chen Y (2006) Reversible assembling of microfluidic devices by aspiration. Microelectron Eng 83(4):1284–1287

Liu C, Cui D, Cai H, Chen X, Geng Z (2006) A rigid poly (dimethylsiloxane) sandwich electrophoresis microchip based on thin-casting method. Electrophoresis 27(14):2917–2923

McDonald JC, Whitesides GM (2002) Poly (dimethylsiloxane) as a material for fabricating microfluidic devices. Acc Chem Res 35(7):491–499

McDonald J, Duffy D, Anderson J, Chiu D, Wu H, Schueller O, Whitesides G (2000) Fabrication of microfluidic systems in poly (dimethylsiloxane). Electrophoresis 21(1):27–40

Oh S (2008) Thick single-layer positive photoresist mold and poly (dimethylsiloxane) (PDMS) dry etching for the fabrication of a glass–PDMS–glass microfluidic device. J Micromech Microeng 18(11):115025–115037

Ohno K, Tachikawa K, Manz A (2008) Microfluidics: applications for analytical purposes in chemistry and biochemistry. Electrophoresis 29(22):4443–4453

Paegel BM, Grover WH, Skelley AM, Mathies RA, Joyce GF (2006) Microfluidic serial dilution circuit. Anal Chem 78(21):7522–7527

Park JW, Vahidi B, Taylor AM, Rhee SW, Jeon NL (2006) Microfluidic culture platform for neuroscience research. Nat Protoc 1(4):2128–2136

Plecis A, Chen Y (2007) Fabrication of microfluidic devices based on glass–PDMS–glass technology. Microelectron Eng 84(5):1265–1269

Qin D, Xia Y, Whitesides GM (2010) Soft lithography for micro-and nanoscale patterning. Nat Protoc 5(3):491–502

Rafat M, Raad DR, Rowat AC, Auguste DT (2009) Fabrication of reversibly adhesive fluidic devices using magnetism. Lab Chip 9(20):3016–3019

Rasponi M, Piraino F, Sadr N, Laganà M, Redaelli A, Moretti M (2011) Reliable magnetic reversible assembly of complex microfluidic devices: fabrication, characterization, and biological validation. Microfluid Nanofluid 10(5):1097–1107

Skelley AM, Kirak O, Suh H, Jaenisch R, Voldman J (2009) Microfluidic control of cell pairing and fusion. Nat Methods 6(2):147–152

Stroock AD, Whitesides GM (2002) Components for integrated poly (dimethylsiloxane) microfluidic systems. Electrophoresis 23:3461–3473

Velve-Casquillas G, Le Berre M, Piel M, Tran PT (2010) Microfluidic tools for cell biological research. Nano Today 5(1):28–47

Weibel DB, Whitesides GM (2006) Applications of microfluidics in chemical biology. Curr Opin Chem Biol 10(6):584–591

Whitesides GM, Ostuni E, Takayama S, Jiang X, Ingber DE (2001) Soft lithography in biology and biochemistry. Annu Rev Biomed Eng 3(1):335–373

Acknowledgments

The authors would like to acknowledge funding from the Major State Basic Research Development Program of China (No. 2011CB707505, 2012CB933303), the National Science Foundation of China (No. 61271161, 60906055), and the CAS Scientific Research Equipment Development Program (No. YZ201143).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chen, Q., Li, G., Nie, Y. et al. Investigation and improvement of reversible microfluidic devices based on glass–PDMS–glass sandwich configuration. Microfluid Nanofluid 16, 83–90 (2014). https://doi.org/10.1007/s10404-013-1222-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-013-1222-9