Abstract

Effect of natural filler amount and kind on the morphological, rheological and mechanical properties of acrylonitrile–butadiene–styrene (ABS) terpolymer was studied in current research. The powdered hazelnut and walnut shells were employed as natural filler with ABS to develop hybrid polymer composites. With single natural filler, it was found that the walnut shell flour was usable for enhancing strengths (tensile, flexural and impact) and modulus (tensile and flexural) in comparison to hazelnut. The highest strengths (tensile, impact and flexural) and flexural modulus were achieved with the amount of 5 wt% hazelnut and 15 wt% walnut shell flour among all hybrid composites. Tensile strain, tensile strength, impact strength, flexural strain and flexural strength of ABS decreased with the mixing of 20 wt% hazelnut and with the mixing of 20 wt% walnut shell flour. The addition of hazelnut shell flour filler alone caused a decrement in melt flow index (MFI) value while the incorporation of walnut shell flour filler alone resulted in an increase in MFI value as compared to pure ABS. It was concluded that hazelnut and/or walnut shell flour-filled polymer composites were usable in applications where lower cost was desirable and some decrements in the mechanical properties were acceptable.

Similar content being viewed by others

References

Ali HQ, Raza MA, Westwood A, Ghauri FA, Asgar H (2019) Development and mechanical characterization of composites based on unsaturated polyester reinforced with maleated high oleic sunflower oil-treated cellulose fiber. Polym Compos 40:901–908

Ribeiro JE, Rocha J, Queijo L (2019) The influence of manufacturing factors in the short-fiber non-woven chestnut hedgehog spine-reinforced polyester composite performance. J Nat Fibers. https://doi.org/10.1080/15440478.2019.1691109

Essabir H, Nekhlaoui S, Malha M, Bensalah MO, Arrakhiz FZ, Qaiss A, Bouhfid R (2013) Bio-composites based on polypropylene reinforced with almond shells particles: mechanical and thermal properties. Mat Des 51:225–230

Liu W, Liu T, Liu H, Xin J, Zhang J, Muhidinov ZK, Liu L (2017) Properties of poly(butylene adipate-co-terephthalate) and sunflower head residue biocomposites. J Appl Polym Sci 134:44644

Food and Agricultural Organization of the United Nations (FAO), https://www.fao.org/faostat/en/#data/QC, 2020 [accessed January 2020].

Balart JF, Garcia-Sanoguera D, Balart R, Boronat T, Sanchez-Nacher L (2018) Manufacturing and properties of biobased thermoplastic composites from poly(lactid acid) and hazelnut shell wastes. Polym Compos 39:848–857

Martinez ML, Moiraghi L, Agnese M, Guzman C (2003) Making and some properties of activated carbon produced from agricultural industrial residues from Argentina. J Argent Chem Soc 91:103–108

Pirayesh H, Khanjanzadeh H, Salari A (2013) Effect of using walnut/almond shells on the physical, mechanical properties and formaldehyde emission of particleboard. Compos Part B Eng 45:858–863

Gungor A, Akbay IK, Ozdemir T (2019) Waste walnut shell as an alternative bio-based filler for the EPDM: mechanical, thermal, and kinetic studies. J Mater Cycles Waste Manage 21:145–155

Balart JF, Fombuena V, Fenollar O, Boronat T, Sanchez-Nacher L (2016) Processing and characterization of high environmental efficiency composites based on PLA and hazelnut shell flour (HSF) with biobased plasticizers derived from epoxidized linseed oil (ELO). Compos Part B Eng 86:168–177

Balart JF, Montanes N, Fombuena V, Boronat T, Sanchez-Nacher L (2018) Disintegration in compost conditions and water uptake of green composites from poly(lactic acid) and hazelnut shell flour. J Polym Environ 26:701–715

Muller M, Valasek P, Linda M, Petrasek S (2018) Exploitation of hazelnut (Corylus avellane) shell waste in the form of polymer-particle biocomposite. Sci Agric Bohem 49:53–59

Barczewski M, Salasinska K, Szulc J (2019) Application of sunflower husk, hazelnut shell and walnut shell as waste agricultural fillers for epoxy-based composites: a study into mechanical behaviour related to structural and rheological properties. Polym Test 75:1–11

Salasinska K, Ryszkowska J (2012) Natural fibre composites from polyethylene waste and hazelnut shell: dimensional stability, physical, mechanical and thermal properties. Compos Interfaces 19:321–332

Singh VK (2015) Mechanical behaviour of walnut Juglans L shell particles reinforced bio-composite. Sci Eng Compos Mater. 22:383–390

Salasinska K, Barczewski M, Gorny R, Klozinski A (2018) Evaluation of highly filled epoxy composites modified with walnut shell waste filler. Polym Bull 75:2511–2528

Ayrilmis N, Kaymakci A, Ozdemir F (2013) Physical, mechanical, and thermal properties of polypropylene composites filled with walnut shell flour. J Ind Eng Chem 19:908–914

Bryskiewicz A, Zieleniewska M, Przyjemska K, Chojnacki P, Ryszkowska J (2016) Modification of flexible polyurethane foams by the addition of natural origin fillers. Polym Deg Stab 132:32–40

Sencan A, Karaboyacı M, Kılıç M (2015) Determination of lead(II) sorption capacity of hazelnut shell and activated carbon obtained from hazelnut shell activated with ZnCl2. Environ Sci Pollut Res 22:3238–3248

ISO 527 (1997) Plastics–determination of tensile properties. International Organization for Standardization, Switzerland

ISO 178:2010(E) (2010) Plastics–determination of flexural properties. International Organization for Standardization, Switzerland

ISO 180:2000(E) (2000) Plastics–determination of izod impact strength. International Organization for Standardization, Switzerland

ISO 1133:2005(E) (2005) Plastics–determination of the melt mass-flow rate (MFR) and the melt volume-flow rate (MVR) of thermoplastics. International Organization for Standardization, Switzerland

Ismail H, Nizam JM, Abdul Khalil HPS (2001) The effect of a compatibilizer on the mechanical properties and mass swell of white rice husk ash filled natural rubber/linear low density polyethylene blends. Polym Test 20:125–133

Li G, Helms JE, Pang S-S, Schulz K (2001) Analytical modelling of tensile strength of particulate-filled composites. Polym Compos 22:593–603

Chevali VS, Nerenz BA, Ulven CA, Kandare E (2015) Mechanical properties of hybrid lignocellulosic fiber-filled acrylonitrile butadiene styrene (ABS) biocomposites. Polym-Plast Technol Eng 54:375–382

Garcia-Garcia D, Carbonell-Verdu A, Jorda-Vilaplana A, Balart R, Garcia-Sanoguera D (2016) Development and characterization of green composites from bio-based polyethylene and peanut shell. J Appl Polym Sci 133:43940

Zahedi M, Pirayesh H, Khanjanzadeh H, Tabar MM (2013) Organo-modified montmorillonite reinforced walnut shell/polypropylene composites. Mat Des 51:803–809

Abdul Khalil HPS, Chow WC, Rozman HD, Ismail H, Ahmad MN, Kumar RN (2001) The effect of anhydride modification of sago starch on the tensile and water absorption properties of sago-filled linear low-density polyethylene (LLDPE). Polym-Plast Technol Eng 40:249–263

Prabhakar MN, Shah AUR, Rao KC, Song J (2015) Mechanical and thermal properties of epoxy composites reinforced with waste peanut shell powder as a bio-filler. Fibers Polym 16:1119–1124

Ayrilmis N, Kaymakci A, Ozdemir F (2013) Sunflower seed cake as reinforcing filler in thermoplastic composites. J Appl Polym Sci 129:1170–1178

Saura-Calixto F, Canellas J, Garcia-Raso J (1983) Determination of hemicellulose, cellulose and lignin contents of dietary fibre and crude fibre of several seed hulls data comparison. Zeitschrift für Lebensmittel-Untersuchung und -Forschung 177:200–202

Klyosov AA (2007) Wood–Plastic Composites. Wiley, New Jersey

Pirayesh H, Khazaeian A (2012) Using almond (Prunus amygdalus L.) shell as a bio-waste resource in wood based composite. Compos Part B. 43:1475–1479

Quiles-Carrillo L, Montanes N, Sammon C, Balart R, Torres-Giner S (2018) Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind Crops Product 111:878–888

Panthapulakkal S, Sain M (2006) Injection molded wheat straw and corn stem filled polypropylene composites. J Polym Environ 14:265–272

Salasinska K, Ryszkowska J (2015) The effect of filler chemical constitution and morphological properties on the mechanical properties of natural fiber composites. Compos Interfaces 22:39–50

Acknowledgements

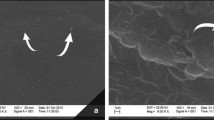

This article is dedicated to the author’s family. The author thanks to Mehmet Kuram for supplying of natural fillers and Ahmet Nazim for helping SEM observations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kuram, E. Rheological, mechanical and morphological properties of hybrid hazelnut (Corylus avellana L.)/walnut (Juglans regia L.) shell flour-filled acrylonitrile butadiene styrene composite. J Mater Cycles Waste Manag 22, 2107–2117 (2020). https://doi.org/10.1007/s10163-020-01094-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-020-01094-3