Abstract

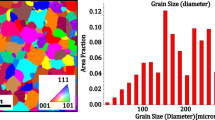

Post-extrusion cold deformation followed by brazing has a significant effect on mechanical properties of micro-channel tubes used in heat exchangers. To understand this relationship, cold rolling with different thickness reductions (0–15%) and a following brazing are conducted on extruded tubes, and the microstructure and strength are examined. The results show that with increasing rolling reduction, tensile strength and burst strength of the as-rolled tubes increase monotonously. While after brazing, both strengths decline obviously, and them decrease first and then increase with increasing rolling reduction. The change is attributed to recrystallization and grain growth observed in the post-braze tubes. Driven by different levels of strain from the rolling, recrystallized grain size increases first and then decreases. At 5% thickness reduction, abnormal large grains form in the web and result in the minimum post-braze strength. Finally, the ductile fraction mode is observed in the web, which shear strength determines the burst strength.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kraft FF (2001) Method for predicting and optimizing the strength of extruded multi-void aluminum heat exchanger tube. SAE Technical Paper Series

Poole WJ et al (2012) A through process model for extruded AA3xxx aluminum alloys. In: Paper presented at 13th international conference on aluminum alloys, Pittsburgh, Pennsylvania, pp 293–298

Güzel A, Jäger A, Parvizian F, Lambers HG, Tekkaya AE, Svendsen B, Maier H (2012) A new method for determining dynamic grain structure evolution during hot aluminum extrusion. J Mater Process Technol 212(1):323–330

Fan X, Tang D, Fang W, Li D, Peng Y (2016) Microstructure development and texture evolution of aluminum multi-port extrusion tube during the porthole die extrusion. Mater Charact 118:468–480

Murai T, Matsuoka SI, Miyamoto S, Oki Y (2003) Effects of extrusion conditions on microstructure and mechanical properties of AZ31B magnesium alloy extrusions. J Mater Process Technol 141(2):207–212

Tang D, Fan X, Fang W, Li D, Peng Y, Wang H (2018) Microstructure and mechanical properties development of micro channel tubes in extrusion, rolling and brazing. Mater Charact 142:449–457

Hall EO (1951) The deformation and ageing of mild steel: III. Discussion of results. Proc Phys Soc B64:747–753

Yu J, Zhao G, Chen L (2016) Analysis of longitudinal weld seam defects and investigation of solid-state bonding criteria in porthole die extrusion process of aluminum alloy profiles. J Mater Process Technol 237:31–47

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Fang, W., Chen, X., Tang, D., Wang, H., Li, D., Peng, Y. (2021). Effects of Residual Strain on Grain Growth of Extruded Aluminum Micro-channel Tubes During Heat Treatment. In: Daehn, G., Cao, J., Kinsey, B., Tekkaya, E., Vivek, A., Yoshida, Y. (eds) Forming the Future. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-75381-8_159

Download citation

DOI: https://doi.org/10.1007/978-3-030-75381-8_159

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-75380-1

Online ISBN: 978-3-030-75381-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)