Abstract

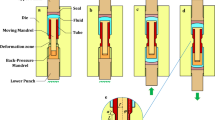

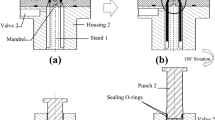

A newly introduced severe plastic deformation process for the production of relatively long ultrafine-grained (UFG) tubes, hydrostatic tube cyclic expansion extrusion (HTCEE), was applied up to two passes on commercially pure copper tubes to study the mechanical characteristics and microstructure of the HTCEE processed samples. In HTCEE process, the pressurized hydraulic fluid around the piece has a main role in the reduction of the friction load leading to a decrease in the required pressing force. After the second pass of HTCEE, a UFG microstructure with an average grain size of ~ 127 nm was observed. In two-pass HTCEE processed tub, more refined and also more homogeneous microstructure was achieved compared to the one-pass HTCEE processed and annealed samples. This type of microstructure caused the increment of yield strength from 75 to 310 MPa, (~ 4.13 times higher), ultimate tensile strength from 207 to 386 MPa (~ 1.86 times higher) and microhardness from ~ 59 to ~ 143 Hv (~ 2.42 times higher). Simultaneously, elongation to failure was lessened from ~ 55 to 37%. In other words, a remarkable increase in the strength and hardness was attained besides a low loss of ductility. Also, microhardness measurements revealed a more homogeneous distribution of hardness in the two-pass processed sample. SEM fractography analysis demonstrated that mostly ductile fracture happened in the HTCEE processed samples. Also, the influence of the HTCEE process on the equivalent plastic strain and also the required force was examined via FEM simulation using Abaqus software. It seems that HTCEE process, by applying low deforming force, possesses the potential of production of tubes with long length having a simultaneous good ductility and strength.

Graphic Abstract

Similar content being viewed by others

References

W. Xia, Z. Chen, D. Chen, S. Zhu, J. Mater. Process. Technol. 209, 26–31 (2009)

A. Al-Zubaydi, R.B. Figueiredo, Y. Huang, T.G. Langdon, J. Mater. Sci. 48, 4661–4670 (2013)

M. Eftekhari, G. Faraji, S. Nikbakht, R. Rashed, R. Sharifzadeh, R. Hildyard, M. Mohammadpour, Mater. Sci. Eng., A 703, 551–558 (2017)

N. Pardis, B. Talebanpour, R. Ebrahimi, S. Zomorodian, Mater. Sci. Eng., A 528, 7537–7540 (2011)

M.T. Pérez-Prado, O. Ruano, Scripta Mater. 51, 1093–1097 (2004)

Q. Wang, Y. Chen, M. Liu, J. Lin, H.J. Roven, Mater. Sci. Eng., A 527, 2265–2273 (2010)

M. Mohebbi, A. Akbarzadeh, Mater. Sci. Eng., A 528, 180–188 (2010)

M. Arzaghi, J. Fundenberger, L. Toth, R. Arruffat, L. Faure, B. Beausir, X. Sauvage, Acta Mater. 60, 4393–4408 (2012)

G. Faraji, P. Yavari, S. Aghdamifar, M.M. Mashhadi, J. Mater. Sci. Technol. 30, 134–138 (2014)

A. Babaei, M. Mashhadi, Prog. Nat. Sci. Mater. Int. 24, 623–630 (2014)

M. Eftekhari, A. Fata, G. Faraji, M. Mashhadi, J. Alloy. Compd. 742, 442–453 (2018)

J. Skiba, W. Pachla, A. Mazur, S. Przybysz, M. Kulczyk, M. Przybysz, M. Wróblewska, J. Mater. Process. Technol. 214, 67–74 (2014)

S. Jamali, G. Faraji, K. Abrinia, Int. J. Adv. Manuf. Technol. 88, 291–301 (2017)

B. Manafi, V. Shatermashhadi, K. Abrinia, G. Faraji, M. Sanei, Int. J. Adv. Manuf. Technol. 82, 1823–1830 (2016)

F. Samadpour, G. Faraji, P. Babaie, S. Bewsher, M. Mohammadpour, Mater. Sci. Eng., A 718, 412–417 (2018)

M.M. Savarabadi, G. Faraji, E. Zalnezhad, J. Alloy. Compd. 785, 163–168 (2019)

G. Faraji, M.M. Savarabadi, US Patent App. 15/989, 141 (2018)

G. Faraji, H. Kim, Mater. Sci. Technol. 33, 905–923 (2017)

J.-C. Hung, C. Hung, J. Mater. Process. Technol. 104, 226–235 (2000)

I. Balasundar, T. Raghu, Mater. Des. 31, 449–457 (2010)

A. Babaei, M. Mashhadi, H. Jafarzadeh, J. Mater. Sci. 49, 3158–3165 (2014)

D.H. Shin, I. Kim, J. Kim, Y.T. Zhu, Mater. Sci. Eng., A 334, 239–245 (2002)

P.S. Roodposhti, N. Farahbakhsh, A. Sarkar, K.L. Murty, Trans. Nonferrous Met. Soc. China 25, 1353–1366 (2015)

H.T. Kashi, M. Bahrami, J.S. Karami, G. Faraji, Iran. J. Mater. Sci. Eng. 14, 32–40 (2017)

N. Pardis, C. Chen, R. Ebrahimi, L.S. Toth, C. Gu, B. Beausir, L. Kommel, Mater. Sci. Eng., A 628, 423–432 (2015)

S. Amani, G. Faraji, K. Abrinia, J. Manuf. Process. 28, 197–208 (2017)

R.Z. Valiev, Y. Estrin, Z. Horita, T.G. Langdon, M.J. Zechetbauer, Y.T. Zhu, JOM 58, 33–39 (2006)

E. Bagherpour, F. Qods, R. Ebrahimi, H. Miyamoto, Mater. Sci. Eng., A 679, 465–475 (2017)

I. Semenova, A. Polyakov, G. Raab, T. Lowe, R. Valiev, J. Mater. Sci. 47, 7777–7781 (2012)

F. Salimyanfard, M.R. Toroghinejad, F. Ashrafizadeh, M. Jafari, Mater. Sci. Eng., A 528, 5348–5355 (2011)

D. Fang, Q. Duan, N. Zhao, J. Li, S. Wu, Z. Zhang, Mater. Sci. Eng., A 459, 137–144 (2007)

V. Tavakkoli, M. Afrasiab, G. Faraji, M. Mashhadi, Mater. Sci. Eng., A 625, 50–55 (2015)

M. Phaniraj, M. Prasad, A. Chokshi, Mater. Sci. Eng., A 463, 231–237 (2007)

M. Ebrahimi, F. Djavanroodi, Prog. Nat. Sci. Mater. Int. 24, 68–74 (2014)

A. Babaei, G. Faraji, M. Mashhadi, M. Hamdi, Mater. Sci. Eng., A 558, 150–157 (2012)

Y. Estrin, A. Vinogradov, Acta Mater. 61, 782–817 (2013)

M.Y. Alawadhi, S. Sabbaghianrad, Y. Huang, T.G. Langdon, J. Mater. Res. Technol. 6, 369–377 (2017)

N. Lugo, N. Llorca, J. Cabrera, Z. Horita, Mater. Sci. Eng., A 477, 366–371 (2008)

K. Edalati, T. Fujioka, Z. Horita, Mater. Sci. Eng., A 497, 168–173 (2008)

S.R. Bahadori, K. Dehghani, F. Bakhshandeh, Mater. Sci. Eng., A 583, 36–42 (2013)

A. Fattah-alhosseini, O. Imantalab, Y. Mazaheri, M. Keshavarz, Mater. Sci. Eng., A 650, 8–14 (2016)

G. Raab, E. Soshnikova, R. Valiev, Mater. Sci. Eng., A 387, 674–677 (2004)

S. Nikbakht, M. Eftekhari, G. Faraji, Modares Mech. Eng. 17, 453–461 (2017)

A. Fata, M. Eftekhari, G. Faraji, M.M. Mashhadi, J. Mater. Eng. Perform. 27, 2330–2337 (2018)

A. Azimi, S. Tutunchilar, G. Faraji, M.B. Givi, Mater. Des. 42, 388–394 (2012)

M. Janeček, J. Čížek, M. Dopita, R. Král, O. Srba, Materials Science Forum (Trans Tech Publications Inc., Zürich, 2008), pp. 440–445

K. Hajizadeh, B. Eghbali, K. Topolski, K. Kurzydlowski, Mater. Chem. Phys. 143, 1032–1038 (2014)

Y. Wang, E. Ma, Acta Mater. 52, 1699–1709 (2004)

R. Kocich, M. Greger, M. Kursa, I. Szurman, A. Macháčková, Mater. Sci. Eng., A 527, 6386–6392 (2010)

K. Edalati, K. Imamura, T. Kiss, Z. Horita, Mater. Trans. 53, 123–127 (2012)

G. Faraji, A. Babaei, M.M. Mashhadi, K. Abrinia, Mater. Lett. 77, 82–85 (2012)

A. Fata, G. Faraji, M. Mashhadi, V. Tavakkoli, Arch. Metall. Mater. 62, 159–166 (2017)

H. Jafarzadeh, K. Abrinia, Mater. Charact. 102, 1–8 (2015)

J. Deng, Y. Lin, S.-S. Li, J. Chen, Y. Ding, Mater. Des. 49, 209–219 (2013)

R. Artan, A. Tepe, Eur. J. Mech. A/Solids 27, 469–477 (2008)

J. Maciejewski, H. Kopeć, H. Petryk, Eng. Trans. 55, 197–216 (2007)

M. Hakamada, Y. Nakamoto, H. Matsumoto, H. Iwasaki, Y. Chen, H. Kusuda, M. Mabuchi, Mater. Sci. Eng., A 457, 120–126 (2007)

Acknowledgements

This work was supported by Iran National Science Foundation (INSF).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Motallebi Savarabadi, M., Faraji, G. & Eftekhari, M. Microstructure and Mechanical Properties of the Commercially Pure Copper Tube After Processing by Hydrostatic Tube Cyclic Expansion Extrusion (HTCEE). Met. Mater. Int. 27, 1686–1700 (2021). https://doi.org/10.1007/s12540-019-00525-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00525-7