Abstract

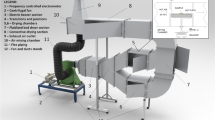

A conveyor-belt dryer was developed using a combined infrared and hot air heating system that can be used in the drying of fruits and vegetables. The drying system having two chambers was fitted with infrared radiation heaters and through-flow hot air was provided from a convective heating system. The system was designed to operate under either infrared radiation and cold air (IR-CA) settings of 2000 W/m2 with forced ambient air at 30 °C and air flow of 0.6 m/s or combined infrared and hot air convection (IR-HA) dryer setting with infrared intensity set at 2000 W/m2 and hot at 60 °C being blown through the dryer at a velocity of 0.6 m/s or hot air convection (HA) at an air temperature of 60 °C and air flow velocity 0.6 m/s but without infrared heating. Apple slices dried under the different dryer settings were evaluated for quality and energy requirements. It was found that drying of apple (Golden Delicious) slices took place in the falling rate drying period and no constant rate period of drying was observed under any of the test conditions. The IR-HA setting was 57.5 and 39.1 % faster than IR-CA and HA setting, respectively. Specific energy consumption was lower and thermal efficiency was higher for the IR-HA setting when compared to both IR-CA and HA settings. The rehydration ratio, shrinkage and colour properties of apples dried under IR-HA conditions were better than for either IR-CA or HA.

Similar content being viewed by others

References

Afzal TM, Abe T, Hikida Y (1999) Energy and quality aspects during combined FIR-convective drying of barley. J Food Eng 42:177–182

Al-Khuseibi MK, Sablani SS, Perera CO (2005) Comparison of water blanching and high hydrostatic pressure effects on drying kinetics and quality of potato. Dry Technol 23:2449–2461

AOAC. (1990). Official methods of analysis (12th ed.), Association of Official Analytical Chemists. Washington, DC.

Baysal T, Icier F, Ersus S, Yildiz H (2003) Effects of microwave and infrared drying on the quality of carrot and garlic. Eur Food Res Technol 218:68–73

Bircan K, Erenturk S (2010) Drying characteristics of mistletoe (Viscum album L.) in convective and UV combined convective type dryers. Ind Crop Prod 32:394–399

Celma AR, Rodriguez FL, Blazquez FC (2009) Experimental modelling of infrared drying of industrial grape by-products. Food Bioprod Process 87:247–253

Celma AR, Rojas S, Rodriguez FL (2008) Mathematical modeling of thin layer infrared drying of wet olive husk. Chem Eng Process 47:1810–1818

El-Beltagy A, Gamea GR, Amer Essa AH (2007) Solar drying characteristics of strawberry. J Food Eng 78:456–464

EL-Mesery HS, Mwithiga G (2012) Comparison of a gas fired hot-air dryer with an electrically heated hot-air dryer in terms of drying process, energy consumption and quality of dried onion slices. Afr J Agric Res 7(31):4440–4452

El-Sebaii AA, Aboul-Enien S, Ramadan MRI, El-Gohary HG (2002) Empirical correlation for drying kinetics of some fruits and vegetables. Energy 27:845–859

Hebbar UH, Ramesh MN (2005) Optimisation of processing conditions for infrared drying of cashew kernels with taste. J Sci Food Agric 85:865–871

Hebbar UH, Vishwanathan KH, Ramesh MN (2004) Development of combined infrared and hot air dryer for vegetables. J Food Eng 65:557–563

Kiranoudis CT, Markatos NC (2000) Pareto design of conveyor belt dryers. J Food Eng 46:145–155

Koc B, Eren I, Ertekin FK (2008) Modelling bulk density, porosity and shrinkage of quince during drying: The effect of drying method. J Food Eng 85:340–349

Kocabiyik H, Tezer D (2009) Drying of carrot slices using infrared radiation. Int J Food Sci Technol 44:953–959

Krokida MK, Maroulis ZB (2001) Structural properties of dehydrated products during rehydration. Int J Food Sci Technol 36(5):529–538

Lewicki PP (1998) Some remarks on rehydration of dried foods. J Food Eng 36:81–87

Maskan M (2001) Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying. J Food Eng 48:177–182

Mayor L, Sereno AM (2004) Modelling shrinkage during convective drying of food materials: a review. J Food Eng 61:373–386

Mongpraneet S, Abe T, Tsurusaki T (2002) Far infrared-vacuumand -convection drying of welsh onion. Trans Am Soc Agric Eng 45:1529–1535

Motevali A, Minaei S, Khoshtagaza MH, Amirnejat H (2011) Comparison of energy consumption and specific energy requirements of different methods for drying mushroom slices. Energy 36:6433–6441

Nowak D, Lewicki PP (2004) Infrared drying of apple slices. Innov Food Sci Emerg Technol 5:353–360

Nuthong P, Achariyaviriya A, Namsanguan K, Achariyaviriya S (2011) Kinetics and modeling of whole longan with combined infrared and hot air. J Food Eng 102(2011):233–239

Planinić M, Velić D, Tomas S, Bilić M, Bucić A (2005) Modelling of drying and rehydration of carrots using Peleg’smodel. Eur Food Res Technol 221:446–451

Popiel CO, Wojtkowiak J (2007) Simple formulas for thermophysical properties of liquid water for heat calculations (from 0 to 150 °C). Heat transf eng 19(1):87–101

Prakash S, Jha SK, Datta N (2003) Performance evaluation of blanched carrots dried by three different driers. J Food Eng 62(3):305–313

Reyes A, Vega R, Bustos R, Araneda C (2008) Effect of processing conditions on drying kinetics and particle microstructure of carrot. Dry Technol 26:1272–1285

Sacilik K, Elicin AK (2006) The thin layer drying characteristics of organic apple slices. J Food Eng 73:281–289

Sakai N, Hanzawa T (1994) Applications and advances in far infrared heating in Japan. Trends Food Sci Technol 5:357–362

Sandu C (1986) Infrared radiative drying in food engineering: a process analysis. Biotechnol Prog 2:109–119

Schultz EL, Mazzuco MM, Machado RAF, Bolzan A, Quadriand MB, Quadri MGN (2007) Effect of pre–treatment on drying, density and shrinkage of apple slices. J Food Eng 78:1103–1110

Sharma GP, Prasad S (2001) Drying of garlic (Allium sativum) cloves by microwave-hot air combination. J Food Eng 50:99–105

Sharma GP, Prasad S (2006) Specific energy consumption in microwave drying of garlic cloves. Energy 31:1921–1926

Sharma GP, Verma RC, Pathare P (2005) Thin-layer infrared radiation drying of onion slices. J Food Eng 67:361–366

Singh S, Raina CS, Bawa AS, Saxena DC (2006) Effect of pretreatments on drying and rehydration kinetics and solar of sweet potato slices. Dry Technol 24:1487–1494

Soysal A (2004) Microwave drying characteristics of parsley. Biosyst Eng 89(2):167–173

Sun J, Hu X, Zhao G, Wu J, Wang J, Chen F, Liao X (2007) Characteristics of thin layer infrared drying of apple pomace with and without hot air pre-drying. Food Sci Technol Int 13(2):91–97

Tarhan S, Telci I, TanerTuncay M, Polatci H (2010) Product quality and energy consumption when drying peppermint by rotary drum dryer. Ind Crop Prod 32:420–427

Tippayawong N, Tantakitti C, Thavornun S, Peerawanitkul V (2009) Energy conservation in drying of peeled longan by forced convection and hot air recirculation. Biosyst Eng 104:199–204

Togrul H (2005) Simple modeling of infrared drying of fresh apple slices. J Food Eng 71:311–323

Vishwanathan KH, Hebbar UH, Raghavarao KSMS (2010) Hot Air assisted infrared drying of vegetables and its quality. Food Sci TechnologyRes 16(5):381–388

Wang J, Sheng K (2006) Far infrared and microwave drying of peach. Lebensm Wiss Technol 39:247–255

Wang N, Brennan JG (1995) Changes in structure, density and porosity of potato during dehydration. J Food Eng 24:61–76

Wang Z, Sun J, Liao X, Chen F, Zhao G, Wu J, Hu X (2007) Mathematical modeling on hot air drying of thin layer apple pomace. Food Res Int 40:39–46

Wanyo P, Siriamornpun S, Meeso N (2011) Improvement of quality and antioxidant properties of dried mulberry leaves with combined far-infrared radiation and air convection in Thai tea process. Food and Bioprod Process 89:22–30

Wills R, McGalsson B, Graham D, Joice D (1998) Post harvest: an introduction to physiology and Handling of Fruit, vegetables and ornaments. Hyde park press Adelaide, South Australia

Zhu K, Zou J, Chu Z, Li X (2002) Heat and mass transfer of seed drying in a two pass infrared radiation vibrated bed. Heat Transfer—Asian Res 31(2)):141–147

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

El-Mesery, H.S., Mwithiga, G. Performance of a convective, infrared and combined infrared- convective heated conveyor-belt dryer. J Food Sci Technol 52, 2721–2730 (2015). https://doi.org/10.1007/s13197-014-1347-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-014-1347-1