Abstract

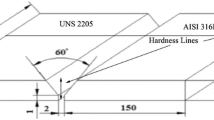

In the present work, dissimilar welding between UNS S32205 duplex stainless steel (DSS) and 316L austenitic stainless steel (ASS) was performed by using gas tungsten arc welding and ER2209 filler at two different heat inputs (0.52 and 0.98 kJ/mm). Microstructures were characterized using reflected light optical microscope and scanning electron microscope. Micro-hardness and tensile properties were measured across the weld for both the heat inputs. The microstructure of the welded region was primarily austenitic (for both heat inputs) with Widmanstätten morphology. The grain size of the heat affected zone on DSS side was very large (~200 µm) for the high heat input sample with the presence of partially transformed austenite and acicular austenite. The precipitation of intermetallic phases and carbides was not observed for both the heat inputs. The proportion of ferrite in the weld metal (as measured by feritscope) was higher for the high heat input sample than the low heat input sample. During the tensile test, fracture occurred in 316L ASS base metal (because of its lower strength) in ductile manner. For high heat input welds, the impact tested sample showed the presence of fine spherical precipitates rich in Cr, Mn and Fe in the fracture surface of weld metal.

Similar content being viewed by others

References

Davis J R (ed) ASM Speciality Handbook: Stainless Steels. ASM International, Geauga (1994).

Armas I A, and Moreuil S D, Duplex Stainless Steels, Wiley, London (2009).

Lippold J C, and Kotecki D J, Welding Metallurgy and Weldability of Stainless Steels, Wiley, New York (2005).

Kou S, Welding Metallurgy, Wiley, New York (2003).

Kashiwar A, Vennela N P, Kamath S L, and Khatirkar R K, Mater Charact 74 (2012) 55.

Badji R, Bouabdallah M, Bacroix B, Kahloun C, Belkessa B, and Maza M, Mater Charact 59 (2008) 447.

Gideon B, Ward L, and Biddle G, J Miner Mater Charact Eng 7 (2008) 247.

Liao J, ISIJ Int 41 (2000) 460.

Sun Z, and Karppi R, J Mater Process Technol 59 (1996) 257.

Bettahar K, Bouabdallah M, Badji R, Gaceb M, Kahloun C, and Bacroix B, Mater Des 85 (2015) 221.

Kaya Y, and Kahraman N, Mater Des 52 (2013) 367.

Srinivasan P B, Muthupandi V, Dietzel W, and Sivan V, Mater Des 27 (2006) 182.

Hajiannia I, Shamanian M, and Kasiri M, Mater Des 50 (2013) 566.

Wang W, Lu Y, Ding X, and Shoji T, Mater Charact 107 (2015) 255.

Chung W C, Huang J Y, Tsay L W, and Chen L W, Mater Trans 52 (2011) 12.

Sadeghian M, and Shamanian M, Mater Des 60 (2014) 678.

Rahmani M, Eghlimi A, and Shamanian M, J Mater Eng Perform 23 (2014) 3745.

Barnhouse E J, and Lippold J C, Weld J 77 (1998) 477.

Kumar S, and Shahi A S, Mater Des 32 (2011) 3617.

ASTM International E3-95. Standard practice for preparation of metallographic specimens.

ASM International, ASM Handbook, Metallography and Microstructures, vol. 9, ASM International, Materials Park, Ohio (2004).

Manual: FERITSCOPE FMP30, Helmut Fisher GmBH, Germany.

ANSI/AWS A4.2. Standard procedures for calibrating magnetic instruments to measure the delta ferrite content of austenitic and duplex ferritic–austenitic stainless steel weld metal. PA: ANSI/AWS Standard (1997).

ASTM International E08-03. Standard test methods for tension testing of metallic materials.

ASTM International E23-16b. Standard test methods for notched bar impact testing of metallic materials.

Lu S, Fujji H, Sugiyama H, Tanaka M, and Nogi K, Mater Trans 43 (2002) 2926.

Eghlimi A, Shamanian M, and Raeissi K, Surf Coat Technol 244 (2014) 45.

Muthupandi V, Srinivasan P B, Seshadri S K, and Sundaresan S, Mater Sci Eng A 358 (2003) 9.

Lippold J C, Baeslack W A, and Varol I, Weld J 1 (2003) 1S.

Wang J, Lu M, Zhang L, Chang W, Xu L, and Hu L, Int J Miner Metall Mater 19 (2012) 518.

Nelson T W, Lippold J C, and Mills M J, Weld J 79 (2000) 267S.

Unnikrishnan R, Idury K S N S, Ismail T P, Bhadauria A, Shekhawat S K, Khatirkar R K, and Sapate S G, Mater Charact 93 (2014) 10.

Kotecki D J, Weld J 65 (1986) 273.

Acknowledgements

The authors would like to thank The Director, VNIT Nagpur for providing necessary facilities and constant encouragement to publish this paper. Thanks are also due to Ms. V. Patankar for her help in mechanical testing and Ms. M. D. Jawale for her help in microstructural examination.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, N., Kumar, A., Gupta, A. et al. Gas Tungsten Arc Welding of 316L Austenitic Stainless Steel with UNS S32205 Duplex Stainless Steel. Trans Indian Inst Met 71, 361–372 (2018). https://doi.org/10.1007/s12666-017-1167-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1167-x