Abstract

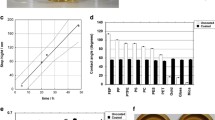

Biocoatings concentrate living, nongrowing microbes in nanoporous adhesive polymer films. Any microbial activity or trait of interest can be intensified and stabilized in biocoatings. These films will dramatically expand the functionality of waterborne coatings. Many microbes contain enzyme systems which are unstable when purified. Therefore, thin polymer coatings of active microbes are a revolutionary approach to stabilize living cells as industrial or environmental biocatalysts. We have demonstrated that some microbes survive polymer film formation embedded in nontoxic adhesive waterborne binders by controlling formulation and drying. Biocoatings can be a single layer of randomly oriented microbes or highly structured multilayer films combining monolayers of different types of microbes on solid, porous, or flexible substrates. They can be formed by drawdown or ink-jet deposition, convective sedimentation assembly, dielectrophoresis, or coated onto or embedded within papers. Controlled drying generates nanoporous microstructure; the pores are filled with a carbohydrate glass which stabilizes the entrapped dehydrated microbes. When the coating is rehydrated, the carbohydrates diffuse out generating nanopores. The activity of biocoatings can be 100s of g L−1 (coating volume) h−1 stabilized for 100–1000s of hours, and therefore, they represent a new approach to process intensification (PI) using thin liquid film bioreactors. A current challenge is that many microbes being engineered as environmental, solar, or carbon recycling biocatalysts do not naturally survive film formation. The mechanisms of dehydration damage that occur during biocoating formulation, ambient drying, and during dry storage have begun to be studied. Critical to preserving microbe viability are minimizing osmotic stress, toxic monomers, biocides, and utilizing polymer chemistries that generate strong wet adhesion with arrested coalescence (nanoporosity). Therefore, controlling desiccation, drying rate/uniformity, and residual moisture are important. Optimization of biocoating activity can be affected at multiple stages—cellular engineering prior to coating (preadaptation), formulation, deposition (film thickness), film formation/drying (generates microstructure), dry storage (minimize metabolic activity), and rehydration. Gene induction (activation) leading to enzyme synthesis following rehydration has been demonstrated. However, little is known about gene regulation in nongrowing microbes. Challenges to optimizing biocoating activity include generating stable film porosity, strong wet adhesion, control of residual water content/form/distribution, and nondestructive measurement of entrapped microbe viability and activity. Indirect methods to measure viability include vital staining, enzyme activity, reporter genes, response to light, confocal fluorescent microscopy, and ATP content. Microbes containing stress-inducible reporter genes can be used to monitor cell stress during formulation, film formation, and drying. Future cellular engineering to optimize biocoatings includes desiccation tolerance, light reactivity (photoefficiency), response to oxidative stress, and cell surface-to-polymer or substrate adhesion. Preservation of microbial activity in waterborne coatings could lead to high intensity biocatalysts for environmental cleaning, gaseous carbon recycling, to produce H2 or electricity from microbial fuel cells, delivery of probiotics, or for biosolar energy harvesting.

Similar content being viewed by others

References

Flickinger, MC, Schottel, JL, Bond, DR, Aksan, A, Scriven, LE, “Painting and Printing Living Bacteria: Engineering Nanoporous Biocatalytic Coatings to Preserve Microbial Viability and Intensify Reactivity.” Biotechnol. Prog, 23 2–17 (2007)

Keddie, JL, Routh, AF, Fundamentals of Latex Film Formation, Springer (2010), ISBN 978-90-481-2844-0

Overbeek, A, “Polymer Heterogeneity in Waterborne Coatings.” J. Coat. Technol. Res., 7 1–21 (2010)

Gosse, JL, Engel, BJ, Hui, J-CH, Harwood, CS, Flickinger, MC, “Progress Toward a Biomimetic Leaf: 4,000 h of Hydrogen Production by Coating-Stabilized Nongrowing Photosynthetic Rhodopseudomonas palustris.” Biotechnol. Prog., 26 907–918 (2010)

Bernal, IO, Mooney, CB, Flickinger, MC, “Specific Photosynthetic Rate Enhancement by Cyanobacteria Coated onto Paper Enables Engineering of Highly Reactive Cellular Biocomposite ‘Leaves’.” Biotechnol. Bioeng., 111 993–2008 (2014)

Cortez, S, Nicolau, A, Flickinger, MC, Mota, M, “Biocoatings: A New Challenge for Environmental Biotechnology.” Biochem. Eng. J., 121 25–37 (2017)

Fu, N, Chen, XD, “Towards a Maximal Cell Survival in Convective Thermal Drying Processes.” Food Res. Int., 44 1122–1149 (2011)

Estrada, JM, Bernal, OI, Flickinger, MC, Muñoz, R, Deshusses, M, “Biocatalytic Coatings for Air Pollution Control: A Proof of Concept Study on VOC Biodegradation.” Biotechnol. Bioeng., 112 263–271 (2015)

Swope, KL, Flickinger, MC, “Activation and Regeneration of Whole Cell Biocatalysts: Initial and Periodic Induction Behavior in Starved E. coli after Immobilization in Thin Synthetic Films.” Biotechnol. Bioeng., 51 360–370 (1996)

Lyngberg, OK, Stemke, DJ, Schottel, JL, Flickinger, MC, “A Single-Use Luciferase-based Mercury Biosensor using Escherichia coli HB101 Immobilized in a Latex Copolymer Film.” J. Ind. Microbiol. Biotechnol., 23 668–676 (1999)

Lyngberg, OK, Ng, CP, Thiagarajan, V, Scriven, LE, Flickinger, MC, “Engineering the Microstructure and Permeability of Thin Multilayer Latex Biocatalytic Coatings Containing E. coli.” Biotechnol. Prog., 17 1169–1179 (2001)

Mota, MA, Yelshin, M, Fidaleo, M, Flickinger, MC, “Modeling Diffusivity in Porous Polymeric Membranes with an Intermediate Layer Containing Microbial Cells.” Biochem. Eng. J., 37 285–293 (2007)

Fidaleo, M, Flickinger, MC, “Engineering and Modeling of Thin, Adhesive, Microbial Biocatalytic Coatings for High Intensity Oxidations in Multi-phase Microchannel Bioreactors.” Chem. Eng. Sci., 66 3251–3257 (2011)

Lyngberg, OK, Solheid, C, Charaniya, S, Ma, Y, Thiagarajan, V, Scriven, LE, Flickinger, MC, “Permeability and Reactivity of Thermotoga maritima in Latex Bimodal Blend Coating at 80°C: A Model High Temperature Biocatalytic Coating.” Extremophiles, 9 197–207 (2005)

Schottel, JL, Orwin, PM, Anderson, CR, Flickinger, MC, “Spatial Expression of a Mercury-inducible Green Fluorescent Protein within a Nonporous Latex-based Biosensor Coating.” J. Ind. Microbiol. Biotechnol., 35 283–290 (2008)

Gosse, JL, Flickinger, MC, “What’s So Interesting about Microbial Coatings?” American Coatings Conference: Science Today–Coatings Tomorrow session. Charlotte, NC (2010)

Bernal, IO, “Mimicking the Plant Leaf: Cellular Composite Materials for Capturing Solar Energy and Gas-Phase Biocatalysis.” PhD Thesis, North Carolina State University, Raleigh, NC (2014)

Gosse, JL, Chinn, MS, Grunden, AM, Bernal, OI, Jenkins, JS, Yeager, C, Kosourov, S, Seibert, M, Flickinger, MC, “A Versatile Method for Preparation of Hydrated Microbial-latex Biocatalytic Coatings for Gas Absorption and Gas Evolution.” J. Ind. Microbiol. Biotechnol., 39 1269–1278 (2012)

Schulte, MJ, Wiltgen, J, Ritter, J, Mooney, CB, Flickinger, MC, “A High Gas Fraction, Reduced Power Syngas Bioprocessing Method Demonstrated with a Clostridium ljungdahlii OTA1 Paper Biocomposite.” Biotechnol. Bioeng., 113 1913–1923 (2016)

Piskorska, M, Soule, T, Gosse, JL, Milliken, C, Flickinger, MC, Smith, GW, Yeager, CM, “Preservation of H2 Production Activity in Nanoporous Latex Coatings of Rhodopseudomonas palustris CGA009 During Dry Storage at Ambient Temperatures.” Microb. Technol., 6 515–525 (2013)

Bernal, OI, Pawlak, JJ, Flickinger, MC, “Microbial Paper: A Cellulose Fiber-based Photo-absorber Producing Hydrogen Gas from Acetate using Dry-stabilized Rhodopseudomonas palustris.” BioResources, 12 4013–4030 (2017)

Polle, JEW, Kanakagiri, S, Jin, E, Masuda, T, Melis, A, “Truncated Chlorophyll Antenna Size of the Photosystems – a Practical Method to Improve Microalgal Productivity and Hydrogen Production in Mass Culture.” Int. J. Hydrogen Energy, 27 1257–1264 (2002)

Melis, A, “Solar Energy Conversion Efficiencies in Photosynthesis: Minimizing the Chlorophyll Antennae to Maximize Efficiency.” Plant Sci., 177 272–280 (2009)

Melis, A, Melnicki, MR, “Integrated Biological Hydrogen Production.” Int. J. Hydrogen Energy, 31 1563–1573 (2006)

Kosourov, S, Ghirardi, ML, Seibert, M, “A Truncated Antenna Mutant of Chlamydomonas reinhardtii Can Produce More Hydrogen than the Parental Strain.” Int. J. Hydrogen Energy, 36 2044–2048 (2011)

Eroglu, E, Melis, A, “Microalgal Hydrogen Research.” Int. J. Hydrogen Energy, 41 12772–12798 (2017)

Gosse, JL, Engel, BJ, Rey, F, Harwood, CS, Scriven, LE, Flickinger, MC, “Hydrogen Production by Photoreactive Nanoporous Latex Coatings of Nongrowing Rhodopseudomonas palustris CGA009.” Biotechnol. Prog., 23 124–130 (2007)

Harwood, CS, “Nitrogenase-Catalyzed Hydrogen Production by Purple Nonsulfur Photosynthetic Bacteria." In: Wall, JD, Harwood, CS, Demain, A (eds.) Bioenergy, pp. 259–271. ASM Press, Washington, DC (2008). ISBN 978-1-55581-478-6

Gosse, JL, Investigation of Cellular Factors in Nongrowing Rhodopseudomonas palustris Hydrogen Production, PhD Thesis, University of Minnesota, St. Paul, MN (2008)

Azzopardi, BJ, Mudde, RF, Lo, S, Morvan, H, Yan, Y, Zhao, D, Hydrodynamics of Gas-Liquid Reactors, Wiley (2011) ISBN 978-0-47074-771-1

Schulte, MJ, A Biocomposite Biocatalyst for Energy Efficient Gas-to-Liquid Conversion of Carbon Monoxide by Clostridium ljungdahlii OTA1, PhD Thesis, North Carolina State University, Raleigh, NC (2016)

Schulte, MJ, Robinett, M, Weidle, N, Duran, CJ, Flickinger, MC, “Experiments and Finite Element Modeling of Hydrodynamics and Mass Transfer of Continuous Gas-to-Liquid Biocatalysis using a Biocomposite Falling Film Reactor.” (2017) (submitted)

Vertès, AA, Inui, M, Yukawa, H, “Postgenomic Approaches to Using Corynebacteria as Biocatalysts.” Annu. Rev. Microbiol., 66 521–550 (2012)

Amano, R, Nakayama, H, Morohoshi, Y, Kawakatsu, Y, Ferjani, A, Kimura, S, “A Decrease in Ambient Temperature Induces Post-Mitotic Enlargement of Palisade Cells in North American Lake Cress.” PLOS One, 10 10141247 (2015)

Buchholz, K, Kasche, V, Bornscheuer, UT, Biocatalysts and Enzyme Technology (2012), Wiley-Blackwell ISBN 978-3-527-32989-2

Robins, K, Gordon, J, “Whole Cell Production of Fine Chemicals and Intermediates.” In: Tao, J, Kazlauskas, R (eds.) Biocatalysis for Green Chemistry and Chemical Process Development, pp. 299–326. Wiley (2011). ISBN 978-0-470-43778-0

Scherber, C, Schottel JL, Aksan, A, “Membrane Phase Behavior of Escherichia coli during Desiccation, Rehydration and Growth Recovery.” Abstracts/Cryobiology, 59 (2009)

Panikov, NS, Mandalakis, M, Dai, S, Mulcahy, LR, Fowle, W, Garrett, WS, Karger, BL, “Near-zero Growth Kinetics of Pseudomonas putida Deduced from Proteomic Analysis.” Environ. Microbiol., 17 215–228 (2015)

McKinlay, JB, Oda, Y, Rühl, M, Posto, AL, Sauer, U, Harwood, CS, “Non-growing Rhodopseutomonas palustris Increases the Hydrogen Gas Yield from Acetate by Shifting form the Glyoxylate Shunt to the Tricarboxylic Acid Cycle.” J. Biol. Chem., 289 1960–1970 (2014)

Lear, G, Ed, Biofilms in Bioremediation, Caister Academic Press, Norfolk, UK (2016) ISBN 978-1-910190-29-6

Gao, Z, Zhao, H, Li, Z, Tan, X, Lu, X, “Photosynthetic Production of Ethanol from Carbon Dioxide in Genetically Engineered Cyanobacteria.” Energy Environ. Sci., 5 9857–9865 (2012)

Guerrero, F, Carbonell, V, Cossu, M, Correddu, D, Jones, PR, “Ethylene Synthesis and Regulated Expression of Recombinant Protein in Synechocystis sp. PCC 6803.” PLOS One, 7 e50470 (2012)

Halfmann, C, Gu, L, Zhou, R, “Engineering Cyanobacteria for the Production of a Cyclic Hydrocarbon Fuel from CO2 and H2O.” Green Chem., 16 3175–3185 (2014)

Bentley, FK, Zurbriggen, A, Melis, A, “Heterologous Expression of the Mevalonic Acid Pathway in Cyanobacteria Enhances Endogenous Carbon Partitioning to Isoprene.” Mol. Plant, 7 71–86 (2014)

Jenkins, JS, Flickinger, MC, Velev, OD, “Engineering Cellular Photocomposite Materials using Convective Assembly.” Materials, 6 1803–1825 (2013)

Flickinger, MC, Lyngberg, OK, Freeman, EA, Anderson, CR, Laudon, MC, “Formulation of Reactive Nanostructured Adhesive Microbial Ink-Jet Inks for Miniature Biosensors and Biocatalysis.” In: Fernando, RH, Sung, L-P (eds.) Nanotechnology Applications in Coatings, ACS Symposium Series 1008, pp. 156–187, American Chemical Society, Washington, DC (2009). ISBN 978-0-8412-7448-8

Fidaleo, M, Bortone, N, Schulte, M, Flickinger, MC, “Ink-jet Printing of Gluconobacter oxydans: Micropatterned Coatings as High Surface-to-Volume Ratio Bio-Reactive Coatings.” Coatings, 4 1–17 (2014)

Jerrim, LB, Velev, OD, “Deposition of Coatings from Live Yeast Cells and Large Particles by Convective-sedimentation Assembly.” Langmuir, 25 5692–5702 (2009)

Jenkins, JS, Flickinger, MC, Velev, OD, “Deposition of Composite Coatings from Particle-particle and Particle-yeast Blends by Convective Sedimentation Assembly.” J. Coll. Interface. Sci., 380 (2012) 192–200 (2012)

Jenkins, JS, Flickinger, MC, Velev, OD, “Continuous Convective-sedimentation Assembly of Colloidal Microsphere Coatings for Biotechnology Applications.” Coatings, 3 26–48 (2013)

Jenkins, JS, Engineering Multifunctional Living Paints: Thin, Convectively-Assembled Biocomposite Coatings of Live Cells and Colloidal Particles Deposited by Continuous Convective-sedimentation Assembly. PhD Thesis, North Carolina State University, Raleigh, NC (2013)

Bernal, OI, Bharti, B, Flickinger, MC, Velev, OB, “Fabrication of Photoreactive Biocomposite Surfaces via Electric Field Assisted Assembly of Cyanobacteria.” (2017) (submitted)

Jannek, K, “Investigation of Stress-inducible Promoter-lux Fusions for E. coli Gene Expression in Latex Coatings.” Diplomarbeit, Institute for Biotechnology, Technical University of Berlin (2006)

Polzin, RG, Polzin, KA, Laudon, MC, Flickinger, MC, “Detecting Oxidative Stress in Latex Coatings of Chlamydomonas reinhardtii using Escherichia coli Containing a katG-lux Fusions” (2017) (in preparation)

Solheid, CW, Characterization of Bilayer Latex Coatings Containing Viable Gluconobacter oxydans for the Oxidation of D-Sorbitol to L-Sorbose. MS Thesis, University of Minnesota, St. Paul, MN (2003)

Solocinski, J, Schulte, MJ, Wang, M, Kovacs, M, Kilgore, R, Flickinger, MC, Chakraborty, N, “A Method for Quantifying Residual Moisture in Paper Biocomposite Biocatalysts using Raman Microspectroscopy” (2017) (submitted)

Park, JP, Choi, M-J, Kim, SH, Lee, SH, Lee, H, “Preparation of Sticky Escherichia coli through Surface Display of an Adhesive Catecholamine Moiety.” App. Environ. Microbiol., 80 43–53 (2013)

Francisco, JA, Stathopoulos, C, Warren, RAJ, Kilburn, DG, Georgiou, G, “Specific Adhesion and Hydrolysis of Cellulose by Intact Escherichia coli Expressing Surfaced Anchored Cellulase or Cellulose Binding Domains.” Bio/Technology, 11 491–495 (1993)

Liu, Z, Ho, S-H, Sakaki, K, den Haan, R, Inokuma, K, Ogino, C, van Zyl, WH, Hasunuma, T, Kondo, A, “Engineering of a Novel Cellulose-adherent Cellulolytic Saccharomyces cerevisiae for Cellulosic Biofuel Production.” Scientific Reports, 6 24550. doi:10.1038/srep/24550 (2016)

Ragoonanan, V, Malsam, J, Bond, DR, Aksan, A, “Roles of Membrane Structure and Phase Transition on the Hyperosmotic Stress Survival of Geobacter sulfurreducens.” Biochimica et Biophysica Acta, 1778 2283–2290 (2008)

Mao, L, Verwoerd, WS, “Genome-scale Stoichiometry Analysis to Elucidate the Innate Capability of the Cyanobacterium Synechocystis for Electricity Generation.” J. Ind. Microbiol. Biotechnol., 40 1161–1180 (2013)

BIOTECH.PAPERNET.IT

De Barros, JMS, Scherer, T, Charalampopoulos, D, Khutoryansky, VV, Edwards, AD, “A Laminated Polymer Film Formulation for Enteric Delivery of Live Vaccine and Probiotic Bacteria.” Pharmaceutics Drug Del. Pharm. Technol., 103 2022–2032 (2014)

Kalyuzhnaya, MG, Puri, AW, Lidstrom, ME, “Metabolic Engineering in Methanotrophic Bacteria.” Metabolic Eng., 29 142–152 (2015)

Acknowledgments

The authors wish to acknowledge Matthew Gebhard, DSM Coating Resins (formerly at Rohm & Haas), Ian Millichamp, AkzoNobel, and Dirk Mestach, Nuplex Resins BV for providing waterborne binder emulsions. OIB was supported by subcontract AC 70110 O from Savannah River Nuclear Solutions, LLC. JJB and MJS were supported by the National Institutes of Health Molecular Biotechnology/Training Program T32 GM008776-11. MJS and SJD were supported by the U.S. Department of Energy, office of Energy Efficiency and Renewable Energy (EERE) award DE-EE0006877 and the Golden LEAF Biomanufacturing Training and Education Center (BTEC), North Carolina State University. AW was supported by the U.S. National Science Foundation CBET award 1510072.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Flickinger, M.C., Bernal, O.I., Schulte, M.J. et al. Biocoatings: challenges to expanding the functionality of waterborne latex coatings by incorporating concentrated living microorganisms. J Coat Technol Res 14, 791–808 (2017). https://doi.org/10.1007/s11998-017-9933-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-017-9933-6