Abstract

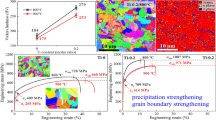

W-(10 to 15) wt.% Ti alloys were sintered at 1400 or 1500 °C and cooled under different cooling conditions. The microstructures and properties of W-Ti alloys were affected by the cooling conditions. XRD, SEM, EBSD, and TEM were carried out to investigate the effects of cooling conditions and sintering temperature on the microstructures of W-Ti alloys. The nanohardness and elastic modulus of the alloys were also investigated. The results showed that when the temperature was 1500 °C, the content of Ti-rich phase in W-(10 to 15) wt.% Ti alloys decreased obviously with the increase of cooling rate (the average cooling rate of furnace cooling, air cooling and water cooling was 0.2, 10, and 280 °C/s, respectively). For the W-10 wt.% Ti alloy, the content decreased from 20.5 to 9.7%, and the grain size decreased from 2.33 to 0.67 μm. When the temperature decreased to 1400 °C, the grain size was also decreased sharply with the increase of cooling rate, but there was a little change in the microstructure. Meanwhile, the grain sizes were smaller than those of the alloys sintered at 1500 °C. The nanohardness and elastic modulus increased with the increase of cooling rate, and the alloys sintered at different temperatures had different nanohardness and elastic modulus which depended on the cooling conditions. Sintering at a proper temperature and then cooling at a certain cooling condition was a useful method to fabricate alloy with less Ti-rich phase and high properties.

Similar content being viewed by others

References

S. Petrović, D. Peruško, B. Gakoviš, M. Mitrić, J. Kovać, A. Zalar, V. Milinović, I. Bogdanovic-Radović, and M. Milosavljević,Effects of Thermal Annealing on Structural and Electrical Properties of Sputtered W-Ti Thin Films, Surf. Coat. Technol., 2010, 204(12–13), p 2099–2102

D. Udler, D. Marpx, and G. Murphy, Tungsten-Titanium Sputtering Target Technology, MRC Technical Note, 1990

Q.X. Wang, Z.K. Fan, and S.H. Liang, Thermal Stability of Nanocrystalline W-Ti Diffusion Barrier Thin Films, Sci. China Technol. Sci., 2010, 53(4), p 1049–1055

Z.H. Wang, M.Y. Chu, X.M. Wang, F. Guo, and X. Zhao, Tungsten-Titanium Targets and Manufacturing Technology, Chin. J. Rare Met., 2006, 30(1), p 95–99 (in Chinese)

R. Daniel, C. John, and J.H. Shi, Tungsten Titanium Targets for VLSI Device Fabrication, MRC Technical Note, 1994

C.E. Wickersham, J.E. Poole, and J.J. Mueller,Particle Contamination During Sputter Deposition of W-Ti Films, J. Vac. Sci. Technol. A, 1992, 10(4), p 1713–1717

C.F. Lo and P. Gilman, Particle Generation in W-Ti Deposition, J. Vac. Sci. Technol. A, 1999, 17(2), p 608–610

Z.H. Wang, X.M. Wang, M.Y. Chu, F. Guo, X. Zhao, and J.Y. Chen, Preparation of W-Ti Sputtering Targets Under Inert Atmosphere, Chin. J. Rare Met., 2006, 30(5), p 688–691 (in Chinese)

T.B. Massalski, Binary Alloy Phase Diagrams, 2nd ed., American Society for Metals, Metals Park, Ohio, 1990, p 288

C.F. Lo, Single Phase Tungsten-Titanium Sputtering Targets and Method of Producing Same, United States Patent: 630155, 1996.

C.E. Wickersham, Method of Producing Tungsten-Titanium Sputter Targets and Targets Produced Thereby, United States Patent: 685789, 1993.

A. Hiraki. Tiatnium-Tungsten Target Material and Manufacturing Method Thereof, United States Patent: 5298338, 1994.

Q.X. Wang, Investigation on Preparation and Application of W-10Ti Alloy Target, Ph.D. thesis, Xi’an University of technology, 2010 (in Chinese).

G.M. Song, Y. Zhou, and Y.J. Wang, The Microstructure and Elevated Temperature Strength of Tungsten-Titanium Carbide Composite, J. Mater. Sci., 2002, 37, p 3541–3548

S.A. Souza, R.B. Manicardi, P.L. Ferrandini, C.R.M. Afonso, A.J. Ramirez, and R. Caram, Effect of the Addition of Ta on Microstructure and Properties of Ti-Nb Alloys, J. Alloys Compd., 2010, 504(2), p 330–340

S.M. Sadrossadat, S. Johansson, and R.L. Peng, EBSD Investigation of the Effect of the Solidification Rate on the Nucleation Behavior of Eutectic Components in a Hypoeutectic Al-Si-Cu Alloy, Met. Mater. Int., 2012, 18(3), p 405–411

Y.P. Wang, L. Zhou, M.F. Zhang, X.Y. Chen, J.M. Liu, and Z.G. Liu, Room-Temperature Saturated Ferroelectric Polarization in BiFeO3 Ceramics Synthesized by Rapid Liquid Phase Sintering, Appl. Phys. Lett., 2004, 84(10), p 1731–1733

S.N. Saud, E. Hamzah, T. Abubakar, S. Farahany, and H.R. Bakhsheshi-Rad, Effect of Quenching Media on Phase Transformation Characteristics and Hardness of Cu-Al-Ni-Co Shape Memory Alloys, J. Mater. Eng. Perform., 2015, 24(4), p 1522–1530

W.L. Dai, S.H. Liang, Y.T. Luo, and Q. Yang, Effect of W Powders Characteristics on the Ti-Rich Phase and Properties of W-10 wt.% Ti Alloy, Int. J. Refract. Met. Hard Mater., 2015, 50, p 240–246

M. Ahmed, D.G. Savvakin, O.M. Ivasishin, and E.V. Pereloma, The Effect of Cooling Rates on the Microstructure and Mechanical Properties of Thermo-Mechanically Processed Ti-Al-Mo-V-Cr-Fe Alloys, Mater. Sci. Eng. A, 2013, 576, p 167–177

F.A. Javid, N. Mattern, M. Samadi Khoshkhoo, M. Stoica, S. Pauly, and J. Eckert, Phase Formation of Cu50-xCoxZr50 (x = 0-20 at.%) Alloys: Influence of Cooling Rate, J. Alloys Compd., 2014, 590, p 428–434

X.J. Tian, S.Q. Zhang, and H.M. Wang,The Influences of Anneal Temperature and Cooling Rate on Microstructure and Tensile Properties of Laser Deposited Ti-4Al-1.5Mn Titanium Alloy, J. Alloys Compd., 2014, 608, p 95–101

G.W. Lee, A.K. Gangopadhyay, and K.F. Kelton, Phase Diagram Studies of Ti-Zr-Ni Alloys Containing Less Than 40 at.% Ni and Estimated Critical Cooling Rate for Icosahedral Quasicrystal Formation from the Liquid, Acta Mater., 2011, 59(12), p 4964–4973

T. Chookajorn and C.A. Schuh, Nanoscale Segregation Behavior and High-Temperature Stability of Nanocrystalline W-20 at.% Ti, Acta Mater., 2014, 73, p 128–138

A.I. Antipov and V.N. Moiseev, Coefficient of β-Stabiization of Titanium Alloys, Met. Sci. Heat Treat., 1997, 39(12), p 499–503

L. Song, X.J. Xu, J. Sun, and J.P. Lin, Cooling Rate Effects on the Microstructure Evolution in the βo Zones of Cast Ti-45Al-8.5Nb-(W, B, Y) Alloy, Mater. Charact., 2014, 93, p 62–67

M.J. Aziz, Model for Solute Redistribution During Rapid Solidification, J. Appl. Phys., 1982, 53(2), p 1158–1168

K. Zhuravleva, M. Bönisch, S. Scudino, M. Calin, L. Schultz, and J. Eckert, Phase Transformations in Ball-Milled Ti-40Nb and Ti-45Nb Powders Upon Quenching from the β-Phase Region, Powder Technol., 2014, 253, p 166–171

A. Carman, L.C. Zhang, O.M. Ivasishin, D.G. Savva, M.V. Matviychuk, and E.V. Pereloma, Role of Alloying Elements in Microstructure Evolution and Alloying Elements Behavior During Sintering of a Near-β Titanium Alloy, Mater. Sci. Eng. A, 2011, 528(3), p 1686–1693

C. Yang, D. Hu, A. Huang, and M. Dixon, Solidification and Grain Refinement in Ti45Al2Mn2Nb1B Subjected to Fast Cooling, Intermetallics, 2013, 32, p 64–71

C.X. Mei, Y. Liu, and X.A. Zhang, Study on Non-equilibrium Effect of Rapid Solidification, Mater. Rev., 2009, 23(6), p 90–93 (in Chinese)

N.Q. Wang and B.Y. Wei, Phase Separation and Structural Evolution of Undercooled Fe-Sn Monotectic Alloy, Mater. Sci. Eng. A, 2003, 345(1–2), p 145–154

L. Kurmanaeva, T.D. Topping, H.M. Wen, H. Sugahara, H. Yang, D.L. Zhang, J.M. Schoenung, and E.J. Lavernia, Strengthening Mechanisms and Deformation Behavior of Cryomilled Al-Cu-Mg-Ag Alloy, J. Alloys Compd., 2015, 632, p 591–603

B. Madhusmita, R. Mythili, S. Raju, and S. Saroja, Effect of Cooling Rate on Mechanism of β → α Phase Transformation on Continuous Cooling in Ti-5Ta-1.8Nb Alloy, J. Alloys Compd., 2013, 553, p 59–68

J. Lu, Y.J. Choi, Z.Z. Fang, H.Y. Sohn, and E. Rönnebro, Hydrogen Storage Properties of Nanosized MgH2-0.1TiH2 Prepared by Ultrahigh-Energy-High-Pressure Milling, J. Am. Chem. Soc., 2009, 131(43), p 15843–15852

C. Jiménez, F. Garcla-Moreno, B. Pfretzschner, M. Klaus, M. Wollgarten, I. Zizak, G. Schumacher, M. Tovar, and J. Banhart, Decomposition of TiH2 Studied In Situ by Synchrotron x-ray and Neutron Diffraction, Acta Mater., 2011, 59(16), p 6318–6330

O.G. Ershova, V.D. Dobrovolsky, Y.M. Solonif, and O.Y. Khyzhun, Hydrogen-Sorption and Thermodynamic Characteristics of Mechanically Grinded TiH1.9 as Studied Using Thermal Desorption Spectroscopy, J. Alloys Compd., 2011, 509(1), p 128–133

R.W. Hayes, D. Witkin, F. Zhou, and E.J. Lavernia, Deformation and Activation Volumes of Cryomilled Ultrafine-Grained Aluminum, Acta Mater., 2004, 52(14), p 4259–4271

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Nos. 51174161 and 51371139), the Pivot Innovation Team of Shaanxi Electric Materials and Infiltration Technique (No. 2012KCT-25), Shaanxi provincial project of special foundation of key disciplines, Natural Science Basic Research Plan in Shaanxi Province of China (No. 2015JM5179), Scientific Research Program Funded by Shaanxi Provincial Education Department of China (No. 15JS072), and 863 Program (No. 2015AA034304).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dai, W., Liang, S., Yang, Q. et al. Microstructures and Properties of W-Ti Alloys Prepared Under Different Cooling Conditions. J. of Materi Eng and Perform 25, 2626–2634 (2016). https://doi.org/10.1007/s11665-016-2146-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2146-9