Abstract

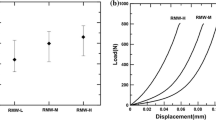

Friction, wear, and friction-induced vibration of brake friction material reinforced with chopped glass fibers were investigated using a Krauss-type tribometer and a one-fifth-scale brake dynamometer. The friction tests were carried out using friction material specimens based on an experimental formulation slid against gray iron disks. The glass fibers increased the surface hardness and contact stiffness of the friction material but decreased compressibility, friction level, and fade resistance. Wear resistance slightly improved with glass fibers at moderate temperatures, whereas it decreased at temperatures beyond the glass transition temperature of the binder resin. Friction oscillation during sliding changed its mode from stick–slip to harmonic oscillation as the velocity increases and was followed by smooth sliding at higher velocities beyond a critical value. Friction-induced vibrations occurred over a wider velocity range when the friction material contained chopped glass fibers, indicating higher propensity of brake-induced noise. Surface analysis after friction tests revealed that contact stiffness of the friction material surface increased due to promoted contact plateaus fostered by the chopped glass fiber bundles.

Similar content being viewed by others

References

Friedrich, K.: Friction and Wear of Polymer Composites. Elsevier, Amsterdam (1986)

Anderson A.E.: Friction materials performance issues. In: Proceedings of Fibers in Friction Material Symposium, pp. 2–49 (1987)

Gopal, P., Dharani, L.R., Blum, F.D.: Fade and wear characteristics of a glass-fiber reinforced phenolic friction material. Wear 174, 119–127 (1994)

Briscoe, B.J., Ramirez, I., Tweedale, P.J.: Friction of aramid fibre composites. IMechE 10, 15–29 (1988)

Kato, T., Magario, A.: The wear of aramid fiber reinforced brake pads: the role of aramid fiber. Tribol. Trans. 37, 559–565 (1994)

Halberstadt, M.L., Rhee, S.K., Mansfield, J.A.: Effects of potassium titanate fiber on the wear of automotive brake linings. Wear 46, 109–126 (1978)

Cho, K.H., Cho, M.H., Kim, S.J., Jang, H.: Tribological properties of potassium titanate in the brake friction material; morphological effects. Tribol. Lett. 32, 59–66 (2008)

Bijwe, J.: Composites as friction materials: recent developments in non-asbestos fiber reinforced friction materials—a review. Polym. Compos. 18, 378 (1997)

Dong, F., Blum, F.D., Dharani, L.R.: Lapinus fiber reinforced phenolic composites: flexural and frictional properties. Polym. Polym. Compos. 4, 155–161 (1996)

Hwang, H.J., Jung, S.L., Cho, K.H., Kim, Y.J., Jang, H.: Tribological performance of brake friction materials containing carbon nanotubes. Wear 268, 519–525 (2010)

Jang, H., Ko, K., Kim, S.J., Basch, R.H., Fash, J.W.: The effect of metal fibers on the friction performance of automotive brake friction materials. Wear 256, 406 (2004)

Park, S.B., Cho, K.H., Jung, S.L., Jang, H.: Tribological properties of brake friction materials with steel fibers. Met. Mater. Int. 15, 27–32 (2009)

Kim, S.J., Cho, M.H., Lim, D.-S., Jang, H.: Synergistic effects of aramid pulp and potassium titanate whiskers in the automotive friction material. Wear 251, 1484–1491 (2001)

Nicholson, G.: Facts About Friction. P & W Price Enterprises Inc, Gedoran America Limited, Winchester (1994)

Kosaka, K., Nishizawa, Y., Kurita, Y., Oura, Y.: Influence of Pad Surface Texture on Disk Brake Squeal. SAE Technical Paper. 2011-01-2354 (2011)

Jang, H.: Origin of friction induced vibration. In: Proceedings of 3rd International Forum on Fundamentals of Sliding Friction and Vibration. Korea University (2013)

Lee, S.M., Shin, M.W., Lee, W.K., Jang, H.: The correlation between contact stiffness and stick–slip of brake friction materials. Wear 302, 1414–1420 (2013)

Kim, S.J., Jang, H.: Friction and wear of friction materials containing two different phenolic resins reinforced with aramid pulp. Tribol. Int. 33, 477–484 (2000)

Nakano, K., Maegawa, S.: Stick–slip in sliding systems with tangential contact compliance. Tribol. Int. 42, 1771–1780 (2009)

Sherif, H.A., Kossa, S.S.: Relationship between normal and tangential contact stiffness of nominally flat surfaces. Wear 151, 49–62 (1991), ibid. Parameters affecting contact stiffness of nominally flat surface, pp. 113–121 (1991)

Cho, M.H., Kim, S.J., Kim, D.H., Jang, H.: Effects of ingredients on tribological characteristics of a brake lining: an experimental case study. Wear 258, 1682–1687 (2005)

Knop, A., Scheib, W.: Chemistry and Application of Phenolic Resins. Springer, New York (1979)

Shin, M.W., Cho, K.H., Lee, W.K., Jang, H.: Tribological characteristics of binder resins for brake friction materials at elevated temperatures. Tribol. Lett. 38, 161–168 (2010)

Bowden, F.P., Tabor, D.: Mechanism of friction and lubrication in metal-working. J. Inst. Petrol. 40, 243–253 (1954)

Rabinowicz, E.: The intrinsic variables affecting the stick–slip process. Proc. Phys. Soc. 71, 668 (1958)

Gao, C., Kuhlmann-Wilsdorf, D., Makel, D.: The dynamic analysis of stick–slip motion. Wear 173, 1–12 (1994)

Jang, H., Lee, J.S., Fash, J.W.: Compositional effects of the brake friction material on creep groan phenomena. Wear 251, 1477–1483 (2001)

Crolla, D.A., Lang, A.M.: Brake noise and vibration-the state of the art. Veh. Tribol. 18, 165–174 (1991)

Brecht, J., Hoffrichter, W., Fohle, A.: Mechanisms of brake creep groan. SAE Trans. 106(2), 3405–3411 (1997)

Nakano, K.: Two dimensionless parameters controlling the occurrence of stick–slip motion in a 1-DOF system with Coulomb friction. Tribol. Lett. 24, 91–98 (2006)

Fuadi, Z., Maegawa, S., Nakano, K., Adachi, K.: Map of low-frequency stick–slip of a creep groan. Proc. Inst. Mech. Eng. 224, 1235–1246 (2010)

Eriksson, M., Bergman, F., Jacobson, S.: Surface characterization of brake pads after running under silent and squealing conditions. Wear 232, 163–167 (1999)

Yoon, S.W., Shin, M.W., Lee, W.G., Jang, H.: Effect of surface contact conditions on the stick–slip behavior of brake friction material. Wear 294, 305–312 (2012)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, S.H., Jang, H. Friction and Vibration of Brake Friction Materials Reinforced with Chopped Glass Fibers. Tribol Lett 52, 341–349 (2013). https://doi.org/10.1007/s11249-013-0221-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-013-0221-z