Abstract

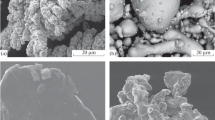

The tribological characteristics of brake friction materials containing different shapes of potassium titanate were investigated. They contain typical ingredients of a non-asbestos organic based friction material, including potassium titanate in the shapes of whiskers, platelets, and splinters. A Krauss type friction tester is used to obtain thermal stability and wear resistance of the friction materials at elevated temperatures. The results showed that the morphology of potassium titanate plays an important role in the formation of contact plateaus and transfer films on the rubbing surfaces, which are closely associated with tribological properties. The friction material with splinter shape potassium titanate shows better friction stability and improved wear resistance compared to those containing other types of potassium titanate due to larger contact plateaus and stable friction films at the sliding interface. On the other hand, the transfer films produced by the friction materials with platelet or whisker potassium titanate are not sustainable at elevated temperatures since they are easily detached during sliding, resulting in poor wear resistance.

Similar content being viewed by others

References

Halberstadt, M.L., Rhee, S.K., Mansfield, J.: Effect of potassium titanate fiber on the wear of automotive brake linings. Wear 46, 109–126 (1976). doi:10.1016/0043-1648(78)90114-X

Kim, S.J., Cho, M.H., Basch, R.H., Fash, J.W., Jang, H.: Tribological properties of polymer composites containing barite or potassium titanate. Tribol. Lett. 17, 655–661 (2004). doi:10.1023/B:TRIL.0000044516.75340.25

Kim, S.J., Cho, M.H., Lim, D.-S., Jang, H.: Synergistic effects of aramid pulp and potassium titante whiskers in the automotive friction material. Wear 251, 1484–1491 (2001). doi:10.1016/S0043-1648(01)00802-X

Addona, T., Konnai, H.: TIBREX-AFA—a new non-fibrous potassium titanate for disk brake pad manufacture. SAE Technical Paper 2004-01-2782 (2004)

State of California EPA, Office of Environmental Health Hazard Assessment Safe Drinking Water and Toxic Enforcement Act of 1986: CAL PROP 65 (2007)

Greim, H. (ed.): DFG Essential MAK Value Documentations. Wiley-VCH Verlag, Weinheim, Germany (2007)

ILO: International Labor Organization: Occupational Safety and Health Series No 64. Safety in the Use of Mineral and Synthetic Fibres. Geneva (1989)

Midander, K., Wallinder, I., Leyfraf, C.: In vitro studies of copper release from powder particles in synthetic biological media. Environ. Pollut. 145, 51–59 (2007). doi:10.1016/j.envpol.2006.03.041

Inada, K., Aki, M., Yamamoto, Y.: Relationship between powder properties of titanate compounds and brake performance. SAE Technical Paper 2005-01-3925 (2005)

Kamifuku, A., Inada, K., Downey, M., Yamamoto, Y.: The brake abrasion properties in two kinds of platelet titanate compound formulations and the swift brake property evaluation by using the thrust test method. SAE Technical Paper 2007-01-3950 (2007)

Cho, M.H., Kim, S.J., Kim, D.H., Jang, H.: Effects of ingredients on tribological characteristics of a brake lining: an experimental case study. Wear 258, 1682 (2005). doi:10.1016/j.wear.2004.11.021

Kim, S.J., Jang, H.: Friction and wear of friction materials containing two different phenolic resins reinforced with aramid pulp. Tribol. Int. 33, 477–484 (2000). doi:10.1016/S0301-679X(00)00087-6

Nam, J., Seferis, J.C.: Initial polymer degradation as a process in the manufacture of carbon–carbon composites. Carbon 30, 751 (1992). doi:10.1016/0008-6223(92)90158-S

Eriksson, M., Jacobson, S.: Tribological surfaces of organic brake pads. Tribol. Int. 33, 817–827 (2000). doi:10.1016/S0301-679X(00)00127-4

Eriksson, M., Bergman, F., Jacobson, S.: On the nature of tribological contact in automotive brakes. Wear 252, 26–36 (2002). doi:10.1016/S0043-1648(01)00849-3

Anderson, A.E.: ASM Handbook, Friction Lubrication, and Wear Technology, vol. 18. ASM International (1992)

Hong, U.S., Jung, S.L., Cho, K.H., Cho, M.H., Kim, S.J., Jang, H.: Wear mechanism of brake friction materials with phenolic resin matrices (submitted) (2008)

Cho, M.H., Cho, K.H., Kim, S.J., Kim, D.H., Jang, H.: The role of transfer layers on friction characteristics in the sliding interface between friction materials against gray iron brake disks. Tribol. Lett. 20, 101–108 (2005). doi:10.1007/s11249-005-8299-6

Acknowledgement

This work was supported by the Korea Science and Engineering Foundation (KOSEF) through the National Research Lab. Program funded by the Ministry of Science and Technology (N. R0A-2007-000-10011-0).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cho, K.H., Cho, M.H., Kim, S.J. et al. Tribological Properties of Potassium Titanate in the Brake Friction Material; Morphological Effects. Tribol Lett 32, 59–66 (2008). https://doi.org/10.1007/s11249-008-9362-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-008-9362-x