Abstract

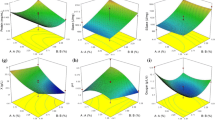

Submerged fermentation (SmF) is an attractive biotechnological option for waste treatment, generating fungal bioprotein from food industry by-products. Using different Rhizopus sp. strains as fermentation agents, this paper describes a global strategy to identify interactions between cultivation parameters (pH 4.75–7.75, 7.5–82.5 g/l glucose, 0.75–3.75 g/l nitrogen, incubation time up to 5 days) for valorization of food industry by-products. Selected parameters and/or their interactions are critical for most of the proposed resulting values, giving the opportunity to optimize the process depending on the objective and making an “in silico” pre-evaluation of the process conditions. SmF of orange molasses leads to a high biomass and protein yield (11.9 g biomass/l and 4.0 g protein/l), with 43.1 ± 0.1% of essential amino acids and chemical oxygen demand (COD) reduction of almost 50%. Experiments with cheese whey result in 76.3 ± 1.1% of glucose consumption and a biomass production of 5.6 ± 2.2 g/l with 48.9 ± 5.1% of essential amino acids. SmF of orange molasses and cheese whey could contribute to promoting a sustainable feed industry while reducing by-product treatment.

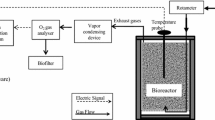

Graphical abstract

Similar content being viewed by others

References

Diario Oficial de la Unión Europea. Directiva (UE) (2018) 2018/851 del Parlamento Europeo y del Consejo de 30 de mayo de 2018 por la que se modifica la Directiva 2008/98/CE sobre los residuos

Angenent LT, Karim K, Al-Dahhan MH, Wrenn BA, Domíguez-Espinosa R (2004) Production of bioenergy and biochemicals from industrial and agricultural wastewater. Trends Biotechnol 22(9):477–485. https://doi.org/10.1016/j.tibtech.2004.07.001

Mollea C, Marmo L, Bosco F (2013) Valorisation of cheese whey, a by-product from the dairy industry. In: Mazzalupo I (ed) Food industry. InTECH, London. https://doi.org/10.5772/53159

Turner TL, Kim E, Hwang C, Zhang GC, Liu JJ, Jin YS (2017) Short communication: conversion of lactose and whey into lactic acid by engineered yeast. J Dairy Sci 100(1):124–128. https://doi.org/10.3168/jds.2016-11784

Carvalho F, Prazeres AR, Rivas J (2013) Cheese whey wastewater: characterization and treatment. Sci Total Environ 445–446:385–396. https://doi.org/10.1016/j.scitotenv.2012.12.038

FAO (2017) Citrus fruit—fresh and processed statistical bulletin 2016. Trade and Market Division, Rome

Rezzadori K, Benedetti S, Amante ER (2012) Proposals for the residues recovery: orange waste as raw material for new products. Food Bioprod Process 90(4):606–614. https://doi.org/10.1016/j.fbp.2012.06.002

Brar SK, Dhillon GS, Soccol CR (2014) Biotransformation of waste biomass into high value biochemicals. Springer, New York. https://doi.org/10.1007/978-1-4614-8005-1

Sadh PK, Duhan S, Duhan JS (2018) Agro-industrial wastes and their utilization using solid state fermentation: a review. Bioresour Bioproces. https://doi.org/10.1186/s40643-017-0187-z

Jin B, Yu Q, van Leeuwen JH, Hung Y-T (2010) An integrated biotechnological process for fungal biomass protein production and wastewater reclamation. In: Wang LK, Tay J-H, Tay STL, Hung Y-T (eds) Environmental bioengineering, vol 11. Humana Press, Totowa, pp 699–721. https://doi.org/10.1007/978-1-60327-031-1_20

Zhang Z, Liu D, Feng F, Li J, Li M, Pang Q, Chen K (2013) Optimization of the nutrition for biodegradation of vinasse by Aspergillus oryzae using response surface methodology. Water Sci Technol 67(4):772–779. https://doi.org/10.2166/wst.2012.631

Nitayavardhana S, Issarapayup K, Pavasant P, Khanal SK (2013) Production of protein-rich fungal biomass in an airlift bioreactor using vinasse as substrate. Bioresour Technol 133:301–306. https://doi.org/10.1016/j.biortech.2013.01.073

Mahboubi A, Ferreira J, Taherzadeh M, Lennartsson P (2017) Production of fungal biomass for feed, fatty acids, and glycerol by Aspergillus oryzae from fat-rich dairy substrates. Fermentation 3(4):48. https://doi.org/10.3390/fermentation3040048

Souza Filho PF, Nair RB, Andersson D, Lennartsson PR, Taherzadeh MJ (2018) Vegan-mycoprotein concentrate from pea-processing industry byproduct using edible filamentous fungi. Fungal Biol Biotechnol 5:5. https://doi.org/10.1186/s40694-018-0050-9

Nair RB, Kabir MM, Lennartsson PR, Taherzadeh MJ, Horvath IS (2018) Integrated process for ethanol, biogas, and edible filamentous fungi-based animal feed production from dilute phosphoric acid-pretreated wheat straw. Appl Biochem Biotechnol 184(1):48–62. https://doi.org/10.1007/s12010-017-2525-1

Kantifedaki A, Kachrimanidou V, Mallouchos A, Papanikolaou S, Koutinas AA (2018) Orange processing waste valorisation for the production of bio-based pigments using the fungal strains Monascus purpureus and Penicillium purpurogenum. J Clean Prod 185:882–890. https://doi.org/10.1016/j.jclepro.2018.03.032

Ferreira JA, Mahboubi A, Lennartsson PR, Taherzadeh MJ (2016) Waste biorefineries using filamentous ascomycetes fungi: present status and future prospects. Bioresour Technol 215:334–345. https://doi.org/10.1016/j.biortech.2016.03.018

Papadaki A, Papapostolou H, Alexandri M, Kopsahelis N, Papanikolaou S, de Castro AM, Freire DMG, Koutinas AA (2018) Fumaric acid production using renewable resources from biodiesel and cane sugar production processes. Environ Sci Pollut Res Int. https://doi.org/10.1007/s11356-018-1791-y

Li X, Zhou J, Ouyang S, Ouyang J, Yong Q (2017) Fumaric acid production from alkali-pretreated corncob by fed-batch simultaneous saccharification and fermentation combined with separated hydrolysis and fermentation at high solids loading. Appl Biochem Biotechnol 181(2):573–583. https://doi.org/10.1007/s12010-016-2232-3

Zheng Y, Wang Y, Zhang J, Pan J (2016) Using tobacco waste extract in pre-culture medium to improve xylose utilization for l-lactic acid production from cellulosic waste by Rhizopus oryzae. Bioresour Technol. https://doi.org/10.1016/j.biortech.2016.06.071

Battaglia E, Benoit I, van den Brink J, Wiebenga A, Coutinho PM, Henrissat B, de Vries RP (2011) Carbohydrate-active enzymes from the zygomycete fungus Rhizopus oryzae: a highly specialized approach to carbohydrate degradation depicted at genome level. BMC Genom 12:38. https://doi.org/10.1186/1471-2164-12-38

Benoit I, Coutinho PM, Schols HA, Gerlach JP, Henrissat B, de Vries RP (2012) Degradation of different pectins by fungi: correlations and contrasts between the pectinolytic enzyme sets identified in genomes and the growth on pectins of different origin. BMC Genom 13:321. https://doi.org/10.1186/1471-2164-13-321

Kupski L, de Carvalho Silvello MA, Fontes MRV, Lima TS, Treichel H, Badiale Furlong E (2015) Rhizopus oryzae cellulases: a new approach to degrading lignocellulosic material. J Food Biochem 39(2):129–138. https://doi.org/10.1111/jfbc.12097

Vaseghi Z, Najafpour GD, Mohseni S, Mahjoub S (2013) Production of active lipase by Rhizopus oryzae from sugarcane bagasse: solid state fermentation in a tray bioreactor. Int J Food Sci Technol 48(2):283–289. https://doi.org/10.1111/j.1365-2621.2012.03185.x

Christen P, Bramorski A, Revah S, Soccol CR (2000) Characterization of volatile compounds produced by Rhizopus strains grown on agro-industrial solid wastes. Bioresour Technol 71(3):211–215. https://doi.org/10.1016/s0960-8524(99)00084-x

Thadathil N, Velappan SP (2014) Recent developments in chitosanase research and its biotechnological applications: a review. Food Chem 150:392–399. https://doi.org/10.1016/j.foodchem.2013.10.083

Ghormade V, Pathan EK, Deshpande MV (2017) Can fungi compete with marine sources for chitosan production? Int J Biol Macromol 104:1415–1421. https://doi.org/10.1016/j.ijbiomac.2017.01.112

Tai C, Li S, Xu Q, Ying H, Huang H, Ouyang P (2010) Chitosan production from hemicellulose hydrolysate of corn straw: impact of degradation products on Rhizopus oryzae growth and chitosan fermentation. Lett Appl Microbiol 51(3):278–284. https://doi.org/10.1111/j.1472-765X.2010.02893.x

Upadhyaya S, Tiwari S, Arora N, Singh DP (2016) Microbial protein: a valuable component for future food security. In: Singh JS, Singh DP (eds) Microbes and environmental management. Studium press, Delhi. https://doi.org/10.13140/rg.2.1.1775.8801

Yadav JSS, Yan S, Ajila CM, Bezawada J, Tyagi RD, Surampalli RY (2016) Food-grade single-cell protein production, characterization and ultrafiltration recovery of residual fermented whey proteins from whey. Food Bioprod Process 99:156–165. https://doi.org/10.1016/j.fbp.2016.04.012

Ferreira JA, Lennartsson PR, Edebo L, Taherzadeh MJ (2013) Zygomycetes-based biorefinery: present status and future prospects. Bioresour Technol 135:523–532. https://doi.org/10.1016/j.biortech.2012.09.064

Souza Filho PF, Zamani A, Taherzadeh MJ (2017) Production of edible fungi from potato protein liquor (PPL) in airlift bioreactor. Fermentation. https://doi.org/10.3390/fermentation3010012

Souza Filho PF, Zamani A, Taherzadeh MJ (2018) Edible protein production by filamentous fungi using starch plant wastewater. Waste Biomass Valoriz. https://doi.org/10.1007/s12649-018-0265-2

Anupama Ravindra P (2000) Value-added food: single cell protein. Biotechnol Adv 18(6):459–479. https://doi.org/10.1016/S0734-9750(00)00045-8

EFFPA (European Former Foodstuff Processor Association). Reducing food waste. https://www.effpa.eu/reducing-food-waste/. Accessed 10 Mar 2018

Karimi S, Soofiani NM, Mahboubi A, Taherzadeh MJ (2018) Use of organic wastes and industrial by-products to produce filamentous fungi with potential as aqua-feed ingredients. Sustainability 10(9):1–19. https://doi.org/10.3390/su10093296

Ministerio de Agricultura, Alimentación y Medio Ambiente. Estimación de precios de piensos: Mayo 2016 (Semanas 18 a 21) (2016). Gobierno de España

Büyükkileci AO (2007) Investigation of sugar metabolism in Rhizopus oryzae. Middle East technical University, Ankara

Satari B, Karimi K, Taherzadeh MJ, Zamani A (2016) Co-production of fungal biomass derived constituents and ethanol from citrus wastes free sugars without auxiliary nutrients in airlift bioreactor. Int J Mol Sci 17(3):302. https://doi.org/10.3390/ijms17030302

Lennartsson PR (2012) Zygomycetes and cellulose residuals: hydrolysis, cultivation and applications. Chalmers University of Technology, Göteborg

Gajdhane SB, Bhagwat PK, Dandge PB (2016) Statistical media optimization for enhanced production of α-galactosidase by a novel Rhizopus oryzae strain SUK. Biocatal Agric Biotechnol 8:301–309. https://doi.org/10.1016/j.bcab.2016.08.016

Karmakar M, Ray RR (2011) A statistical approach for optimization of simultaneous production of beta-glucosidase and endoglucanase by Rhizopus oryzae from solid-state fermentation of water hyacinth using central composite design. Biotechnol Res Int 2011:574–983. https://doi.org/10.4061/2011/574983

Ibarruri J, Hernández I (2018) Rhizopus oryzae as fermentation agent in food derived sub-products. Waste Biomass Valoriz 9(11):2107–2115. https://doi.org/10.1007/s12649-017-0017-8

Zamani A, Edebo L, Sjostrom B, Taherzadeh MJ (2007) Extraction and precipitation of chitosan from cell wall of zygomycetes fungi by dilute sulfuric acid. Biomacromol 8(12):3786–3790. https://doi.org/10.1021/bm700701w

Centro de Investigación y Control de la Calidad (1985) Análisis de alimentos: métodos oficiales y recomendados por el Centro de Investigación y Control de la Calidad. Ministerio de Sanidad y Consumo, Spain

Ferreira JA, Lennartsson PR, Niklasson C, Lundin M, Edebo L, Taherzadeh MJ (2012) Spent sulphite liquor for cultivation of an edible Rhizopus sp. Bioresources 7(1):173–188

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37(8):911–917. https://doi.org/10.1139/o59-099

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428. https://doi.org/10.1021/ac60147a030

Waghmare AG, Salve MK, LeBlanc JG, Arya SS (2016) Concentration and characterization of microalgae proteins from Chlorella pyrenoidosa. Bioresour Bioprocess. https://doi.org/10.1186/s40643-016-0094-8

FAO/WHO/UNU Expert Consultation (2007) Protein and amino acid requirements in human nutrition, WHO Technical Report Series, vol 935. Geneva

Asadollahzadeh M, Ghasemian A, Saraeian A, Resalati H, Taherzadeh M (2018) Production of fungal biomass protein by filamentous fungi cultivation on liquid waste streams from pulping process. Bioresources 13(1):5013–5031. https://doi.org/10.15376/biores.13.3.5013-5031

Anderson JM, Whitcomb JP (2004) RSM simplified: optimizing processes using response surface methods for design of experiments. Taylor & Francis Group, New York. https://doi.org/10.4324/9781482293777

Chatterjee S, Guha AK (2014) A study on biochemical changes during cultivation of Rhizopus oryzae in deproteinized whey medium in relation to chitosan production. Lett Appl Microbiol 59(2):155–160. https://doi.org/10.1111/lam.12259

Das RK, Brar SK, Verma M (2015) A fermentative approach towards optimizing directed biosynthesis of fumaric acid by Rhizopus oryzae 1526 utilizing apple industry waste biomass. Fungal Biol 119(12):1279–1290. https://doi.org/10.1016/j.funbio.2015.10.001

Meussen BJ, de Graaff LH, Sanders JP, Weusthuis RA (2012) Metabolic engineering of Rhizopus oryzae for the production of platform chemicals. Appl Microbiol Biotechnol 94(4):875–886. https://doi.org/10.1007/s00253-012-4033-0

van Leeuwen J, Rasmussen ML, Sankaran S, Koza CR, Erickson DT, Mitra D, Jin B (2012) Fungal treatment of crop processing wastewaters with value-added co-products. In: Gopalakrishnan K, van Leeuwen J, Brown R (eds) Sustainable bioenergy and bioproducts. Green energy and technology. Springer, London, pp 13–44. https://doi.org/10.1007/978-1-4471-2324-8_2

Liu Y, Liao W, Chen S (2008) Co-production of lactic acid and chitin using a pelletized filamentous fungus Rhizopus oryzae cultured on cull potatoes and glucose. J Appl Microbiol 105(5):1521–1528. https://doi.org/10.1111/j.1365-2672.2008.03913.x

Roa Engel CA, Straathof AJJ, Zijlmans TW, van Gulik WM, van der Wielen LAM (2008) Fumaric acid production by fermentation. Appl Microbiol Biotechnol 78(3):379–389. https://doi.org/10.1007/s00253-007-1341-x

Magnuson JK, Lasure LL (2004) Organic acid production by filamentous fungi. In: Tkacz JS, Lange L (eds) Advances in fungal biotechnology for industry, agriculture, and medicine. Springer, Boston, pp 307–340. https://doi.org/10.1007/978-1-4419-8859-1_12

Foster JW, Carson SF, Anthony DS, Davis JB, Jefferson WE, Long MV (1949) Aerobic formation of fumaric acid in the mold Rhizopus nigricans-synthesis by direct C-2 condensation. Proc Natl Acad Sci USA 35(12):663–672. https://doi.org/10.1073/pnas.35.12.663

Zhang K (2012) Fumaric acid fermentation by Rhizopus oryzae with integrated separation technologies. The Ohio State University, Columbus

Chatterjee S, Chatterjee BP, Guha AK (2008) Enhancement of growth and chitosan production by Rhizopus oryzae in whey medium by plant growth hormones. Int J Biol Macromol 42(2):120–126. https://doi.org/10.1016/j.ijbiomac.2007.10.006

Ye X, Yoshida S, Ng TB (2000) Isolation of lactoperoxidase, lactoferrin, α-lactalbumin, β-lactoglobulin B and β-lactoglobulin A from bovine rennet whey using ion exchange chromatography. Int J Biochem Cell Biol 32(11):1143–1150. https://doi.org/10.1016/S1357-2725(00)00063-7

Miles RD, Chapman FA (2006) The benefits of fish meal in aquaculture diets. Institute of Food and Agricultural Sciences, University of Florida, Florida

Nitayavardhana S, Khanal SK (2010) Innovative biorefinery concept for sugar-based ethanol industries: production of protein-rich fungal biomass on vinasse as an aquaculture feed ingredient. Bioresour Technol 101(23):9078–9085. https://doi.org/10.1016/j.biortech.2010.07.048

de Blas C, Mateos GG (2013) Necesidades nutricionales para ganado porcino. FEDNA (Fundación Española para el Desarrollo de la Nutrición Animal)

Ferret A, Calsamiglia S, Bach A, Devant M, Fernández C, García-Rebollar P (2008) Necesidades nutricionales para rumiantes de cebo. FEDNA (Fundación Española para el Desarrollo de la Nutrición Animal)

Lall SP, Tibbetts SM (2009) Nutrition, feeding, and behavior of fish. Vet Clin N Am Exot Anim Pract 12(2):361–372. https://doi.org/10.1016/j.cvex.2009.01.005

Yunoki K, Musa R, Kinoshita M, Oda Y, Ohnishi M (2004) Determinations of triacylglycerol and fatty acid esters in potato pulp fermented with lactic acid-producing fungus. J Oil Chem Soc Jpn 53(11):565–569. https://doi.org/10.5650/jos.53.565

Innes JK, Calder PC (2018) Omega-6 fatty acids and inflammation. Prostaglandins Leukot Essent Fatty Acids 132:41–48. https://doi.org/10.1016/j.plefa.2018.03.004

Kapoor R, Huang YS (2006) Gamma linolenic acid: an antiinflammatory omega-6 fatty acid. Curr Pharm Biotechnol 7(6):531–534

Guerzoni ME, Lanciotti R, Cocconcelli PS (2001) Alteration in cellular fatty acid composition as a response to salt, acid, oxidative and thermal stresses in Lactobacillus helveticus. Microbiology (UK) 147:2255–2264. https://doi.org/10.1099/00221287-147-8-2255

Oda Y, Yajima Y, Kinoshita M, Ohnishi M (2003) Differences of Rhizopus oryzae strains in organic acid synthesis and fatty acid composition. Food Microbiol 20(3):371–375. https://doi.org/10.1016/s0740-0020(02)00131-4

Oliva-Teles A (2012) Nutrition and health of aquaculture fish. J Fish Dis 35(2):83–108. https://doi.org/10.1111/j.1365-2761.2011.01333.x

Mourente G, Tocher DR (1993) Incorporation and metabolism of 14C-labelled polyunsaturated fatty acids in juvenile gilthead sea bream Sparus aurata L. in vivo. Fish Physiol Biochem 10(6):443–453. https://doi.org/10.1007/bf00004599

Ghioni C, Tocher DR, Bell MV, Dick JR, Sargent JR (1999) Low C18 to C20 fatty acid elongase activity and limited conversion of stearidonic acid, 18:4(n–3), to eicosapentaenoic acid, 20:5(n–3), in a cell line from the turbot, Scophthalmus maximus. Biochimica et Biophysica Acta (BBA) Mol Cell Biol Lipids 1437(2):170–181. https://doi.org/10.1016/s1388-1981(99)00010-4

Bankefors J, Kaszowska M, Schlechtriem C, Pickova J, Brännäs E, Edebo L, Kiessling A, Sandström C (2011) A comparison of the metabolic profile on intact tissue and extracts of muscle and liver of juvenile Atlantic salmon (Salmo salar L.)—application to a short feeding study. Food Chem 129(4):1397–1405. https://doi.org/10.1016/j.foodchem.2011.05.081

Abro R, Moazzami AA, Lindberg JE, Lundh T (2014) Metabolic insights in Arctic charr (Salvelinus alpinus) fed with Zygomycetes and fish meal diets as assessed in liver using nuclear magnetic resonance (NMR) spectroscopy. Int Aquat Res. https://doi.org/10.1007/s40071-014-0063-9

Edebo L (2009) Zygomycetes for fish feed. EE.UU. Patent no 20090136617

Lázaro R, Mateos GG (2008) Necesidades nutricionales para avicultura: pollos de carne y aves de puesta. FEDNA (Fundación Española para el Desarrollo de la Nutrición Animal)

National Research Council (1998) Composition of feed ingredients. In: Nutrient requirements of swine. The National Academy Press, Washington DC, pp 124–142. https://doi.org/10.17226/6016

FEDNA. Tablas de ingredientes para piensos: harina de pescado 70/9/13. http://fundacionfedna.org/ingredientes_para_piensos/harina-de-pescado-70913. Accessed 18 Nov 2018

FEDNA. Tablas de ingredientes para piensos: Harina de soja 44% PB. http://fundacionfedna.org/ingredientes_para_piensos/harina-de-soja-44-pb. Accessed 18 Nov 2018

Acknowledgements

Authors thank Vascolac S.L, and Indulleida S.A. for providing the food industry by-products. This work was funded by the Basque Government (Department of economic development and competitiveness and infrastructure development, agriculture, fisheries and food policy). This paper is contribution no 909 from AZTI (Food Research).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ibarruri, J., Hernández, I. Valorization of cheese whey and orange molasses for fungal biomass production by submerged fermentation with Rhizopus sp.. Bioprocess Biosyst Eng 42, 1285–1300 (2019). https://doi.org/10.1007/s00449-019-02127-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-019-02127-4