Abstract

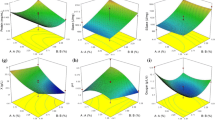

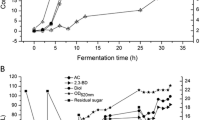

Microbial bioconversion of agro-industrial wastes to green chemicals has become an important objective in industrial biotechnology for lowering the product costs. Therefore, in this work, beet molasses was used as a potential raw material for lactic acid (LA) production by a newly isolated bacterium, Enterococcus faecium S6. The pretreatment of molasses with EDTA has exhibited the highest effectiveness for bioconversion to LA. The optimal medium components and culture conditions were established. Supplementation of molasses by yeast extract (YE) and ammonium chloride have achieved LA production of 11.90 g/L at a yield of 0.71 g/g-consumed sugars and a productivity of 0.33 g/L/h. Various approaches were used for the optimization of relevant factors affecting l-LA production in batch fermentations. Using classical “one-factor-at-a-time” approach, the optimal factors were as follows: sugar concentration, 40 g/L; pH, 7.0; 40 °C; and inoculum size, 10% (v/v) achieving LA at 29.7 g/L. The effects of these five fermentation parameters were further investigated by response surface methodology (RSM) to maximize LA production. The optimized fermentation conditions by RSM were as follows: sugar concentration, 65 g/L; YE, 0.625 g/L; temperature, 42 °C; pH, 6.75; and inoculum size, 9.5% (v/v) that achieved LA production of 41.5 g/L. Further improvements were achieved using repeated batch fermentation that has conducted for 16 runs. Using seed culture pre-adapted to the actual fermentation conditions in repeated batch fermentation led to enhanced LA production with a shorter process time compared to batch fermentation. These results achieved a maximum LA of 64.7 g/L with high yield (0.94 g/g of consumed sugars) and productivity (2.16 g/L/h). This study presented a cost-effective and long-term fermentative production of LA from beet molasses.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding authors on request.

References

Abdel-Rahman MA, Tashiro Y, Sonomoto K (2013) Recent advances in lactic acid production by microbial fermentation processes. Biotechnol Adv 31:877–902. https://doi.org/10.1016/j.biotechadv.2013.04.002

de Lima CJ, Coelho LF, Contiero J (2010) The use of response surface methodology in optimization of lactic acid production: focus on medium supplementation, temperature and pH control. Food Technol Biotechnol 48:175–181 https://www.ftb.com.hr/images/pdfarticles/2010/April-June/48_175.pdf

Tejayadi S, Cheryan M (1995) Lactic acid from cheese whey permeate. Productivity and economics of a continuous membrane bioreactor. Appl Microbiol Biotechnol 43:242–248. https://doi.org/10.1007/BF00172819

Hassan SED, Abdel-Rahman MA, Roushdy MM, Azab MS, Gaber MA (2019) Effective biorefinery approach for lactic acid production based on co-fermentation of mixed organic wastes by Enterococcus durans BP130. Biocatal Agric Biotechnol 20:101203. https://doi.org/10.1016/j.bcab.2019.101203

Abdel-Rahman MA, Hassan SED, Roushdy MM, Azab MS, Gaber MA (2019) Free-nutrient supply and thermo-alkaline conditions for direct lactic acid production from mixed lignocellulosic and food waste materials. Bioresour Technol Rep 7:100256. https://doi.org/10.1016/j.biteb.2019.100256

Rajaeifar MA, Hemayati SS, Tabatabaei M, Aghbashlo M, Mahmoudi SB (2019) A review on beet sugar industry with a focus on implementation of waste-to-energy strategy for power supply. Renew Sust Energ Rev 103:423–442. https://doi.org/10.1016/j.rser.2018.12.056

Gabra FA, Abd-Alla MH, Danial AW, Abdel-Basset R, Abdel-Wahab AM (2019) Production of biofuel from sugarcane molasses by diazotrophic Bacillus and recycle of spent bacterial biomass as biofertilizer inoculants for oil crops. Biocatal Agric Biotechnol 19:101112. https://doi.org/10.1016/j.bcab.2019.101112

Dumbrepatil A, Adsul M, Chaudhari S, Khire J, Gokhale D (2008) Utilization of molasses sugar for lactic acid production by Lactobacillus delbrueckii subsp. delbrueckii mutant Uc-3 in batch fermentation. Appl Environ Microbiol 74:333–335. https://doi.org/10.1128/AEM.01595-07

Litchfield JH (1996) Microbiological production of lactic acid. Adv Appl Microbiol 42:45–95. https://doi.org/10.1016/S0065-2164(08)70372-1

Vidra A, Tóth AJ, Németh Á (2017) Lactic acid production from cane molasses. Waste Treat Recover 2:13–16. https://doi.org/10.1515/lwr-2017-0003

Dai JY, Zhao P, Cheng XL, Xiu ZL (2015) Enhanced production of 2, 3-butanediol from sugarcane molasses. Appl Biochem Biotechnol 175:3014–3024. https://doi.org/10.1007/s12010-015-1481-x

Tsioptsias C, Petridis D, Athanasakis N, Lemonidis I, Deligiannis A, Samaras P (2015) Post-treatment of molasses wastewater by electrocoagulation and process optimization through response surface analysis. J Environ Manag 164:104–113. https://doi.org/10.1016/j.jenvman.2015.09.007

Abdel-Rahman GN, Nassar NR, Heikal YA, Abou-Donia MA, Naguib MM, Fadel M (2016) Effect of different treatments on heavy metal concentration in sugar cane molasses. Int J Agr Biosyst Eng 10:43–48. https://doi.org/10.5281/zenodo.1125003

Parajó JC, Santos V, Dominguez H, Vázquez M (1995) NH4OH-based pretreatment for improving the nutritional quality of single-cell protein (SCP). Appl Biochem Biotechnol 55:133–149. https://doi.org/10.1007/BF02783554

Singh V, Haque S, Niwas R, Srivastava A, Pasupuleti M, Tripathi CKM (2017) Strategies for fermentation medium optimization: an in-depth review. Front Microbiol 7:2087. https://doi.org/10.3389/fmicb.2016.02087

Box GE, Hunter WG, Hunter JS (1979) Statistics for experimenters. J Mark Res 16:291. https://doi.org/10.1002/aic.690250233

Giovanni M (1983) Response surface methodology and product optimization. Food Technol 37:50–83. https://doi.org/10.12691/ajfn-6-4-3

Abdel-Rahman MA, Sonomoto K (2016) Opportunities to overcome the current limitations and challenges for efficient microbial production of optically pure lactic acid. J Biotechnol 236:176–192. https://doi.org/10.1016/j.jbiotec.2016.08.008

Abdel-Rahman MA, Hassan SED, Azab MS, Mahin AA, Gaber MA (2019) High improvement in lactic acid productivity by new alkaliphilic bacterium using repeated batch fermentation integrated with increased substrate concentration. Biomed Res Int 2019:13–13. https://doi.org/10.1155/2019/7212870

Reddy LV, Kim YM, Yun JS, Ryu HW, Wee YJ (2016) l-Lactic acid production by combined utilization of agricultural bioresources as renewable and economical substrates through batch and repeated-batch fermentation of Enterococcus faecalis RKY1. Bioresour Technol 209:187–194. https://doi.org/10.1016/j.biortech.2016.02.115

De Man JC, Rogosa D, Sharpe ME (1960) A medium for the cultivation of lactobacilli. J Appl Microbiol 23:130–135. https://doi.org/10.1111/j.1365-2672.1960.tb00188.x

Lazaridou A, Roukas T, Biliaderis CG, Vaikousi H (2002) Characterization of pullulan produced from beet molasses by Aureobasidium pullulans in a stirred tank reactor under varying agitation. Enzym Microb Technol 31:122–132. https://doi.org/10.1016/S0141-0229(02)00082-0

Kundu S, Panda T, Majumdar SK, Guha B, Bandyopadhyay KK (1984) Pretreatment of Indian cane molasses for increased production of citric acid. Biotechnol Bioeng 26:1114–1121. https://doi.org/10.1002/bit.260260915

Roukas T (1998) Pretreatment of beet molasses to increase pullulan production. Process Biochem 33:805–810. https://doi.org/10.1016/S0032-9592(98)00048-X

Küçükaşik F, Kazak H, Güney D, Finore I, Poli A, Yenigün O, Nicolaus B, Öner ET (2011) Molasses as fermentation substrate for levan production by Halomonas sp. Appl Microbiol Biotechnol 89:1729–1740. https://doi.org/10.1007/s00253-010-3055-8

Abdel-Rahman MA, Hassan SED, El-Din MN et al (2020) One-factor-at-a-time and response surface statistical designs for improved lactic acid production from beet molasses by Enterococcus hirae ds10. SN Appl Sci 2:573. https://doi.org/10.1007/s42452-020-2351-x

Taylor KACC (1996) A simple colorimetric assay for muramic acid and lactic acid. Appl Biochem Biotechnol 56:49–58. https://doi.org/10.1007/BF02787869

Dubois M, Gilles KA, Hamilton JK, Rebers PT, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. https://doi.org/10.1021/ac60111a017

Oderinde RA, Ngoka LC, Adesogan EK (1986) Comparative study of the effect of ferrocyanide and EDTA on the production of ethyl alcohol from molasses by Saccharomyces cerevisiae. Biotechnol Bioeng 28:1462–1465. https://doi.org/10.1002/bit.260281003

Turhan İ, Bialka KL, Demirci A, Karhan M (2010) Enhanced lactic acid production from carob extract by Lactobacillus Casei using invertase pretreatment. Food Biotechnol 24:364–374. https://doi.org/10.1080/08905436.2010.524485

Oh H, Wee Y, Yun J, Ryu H-W (2003) Lactic acid production through cell-recycle repeated-batch bioreactor. Appl Biochem Biotechnol 107:603–613. https://doi.org/10.1385/ABAB:107:1-3:603

De la Torre I, Ladero M, Santos VE (2018) Production of d-lactic acid by Lactobacillus delbrueckii ssp. delbrueckii from orange peel waste: techno-economical assessment of nitrogen sources. Appl Microbiol Biotechnol 102(24):10511–10521. https://doi.org/10.1007/s00253-018-9432-4

Gao X, Qiao SY, Lu WQ (2009) Determination of an economical medium for growth of Lactobacillus fermentum using response surface methodology. Lett Appl Microbiol 49:556–561. https://doi.org/10.1111/j.1472-765X.2009.02705.x

Wee YJ, Kim JN, Yun JS, Ryu HW (2004) Utilization of sugar molasses for economical l(+)-lactic acid production by batch fermentation of Enterococcus faecalis. Enzym Microb Technol 35:568–573. https://doi.org/10.1016/j.enzmictec.2004.08.008

Altaf MD, Venkateshwar M, Srijana M, Reddy G (2007) An economic approach for l-(+) lactic acid fermentation by Lactobacillus amylophilus GV6 using inexpensive carbon and nitrogen sources. J Appl Microbiol 103:372–380. https://doi.org/10.1111/j.1365-2672.2006.03254.x

John RP, Nampoothiri KM, Pandey A (2006) Solid-state fermentation for l-lactic acid production from agro wastes using Lactobacillus delbrueckii. Process Biochem 41:759–763. https://doi.org/10.1016/j.procbio.2005.09.013

Assavasirijinda N, Ge D, Yu B, Xue Y, Ma Y (2016) Efficient fermentative production of polymer-grade d-lactate by an engineered alkaliphilic Bacillus sp. strain under non-sterile conditions. Microb Cell Factories 15(1):3. https://doi.org/10.1186/s12934-015-0408-0

Wang L, Zhao B, Li F, Xu K, Ma C, Tao F et al (2011) Highly efficient production of d-lactate by Sporolactobacillus sp. CASD with simultaneous enzymatic hydrolysis of peanut meal. Appl Microbiol Biotechnol 89:1009–1017. https://doi.org/10.1007/s00253-010-2904-9

Hujanen MLYY, Linko YY (1996) Effect of temperature and various nitrogen sources on l- (+)-lactic acid production by Lactobacillus casei. Appl Microbiol Biotechnol 45(3):307–313. https://doi.org/10.1007/s002530050688

Goksungur Y, Guvenc U (1999) Production of lactic acid from beet molasses by calcium alginate immobilized Lactobacillus delbrueckii IFO 3202. J Chem Technol Biotechnol 74:131–136. https://doi.org/10.1002/(SICI)1097-4660(199902)74:2<131::AID-JCTB996>3.0.CO;2-Q

Monteagudo JM, Rodriguez L, Rincon J, Fuertes J (1994) Optimization of the conditions of the fermentation of beet molasses to lactic acid by Lactobacillus delbrueckii. Acta Biotechnol 14:251–260. https://doi.org/10.1002/abio.370140307

Gao MT, Hirata M, Toorisaka E, Hano T (2009) Development of a fermentation process for production of calcium-l-lactate. Chem Eng Process Process Intensif 48:464–469. https://doi.org/10.1016/j.cep.2008.06.002

Hetényi K, Németh Á, Sevella B (2011) Role of pH-regulation in lactic acid fermentation: second steps in a process improvement. Chem Eng Process Process Intensif 50:293–299. https://doi.org/10.1016/j.cep.2011.01.008

Abdel-Rahman MA, Tashiro Y, Zendo T, Sakai K, Sonomoto K (2015) Enterococcus faecium QU 50: a novel thermophilic lactic acid bacterium for high-yield l-lactic acid production from xylose. FEMS Microbiol Lett 362:1–7. https://doi.org/10.1093/femsle/fnu030

Abdel-Rahman MA, Tashiro Y, Zendo T, Sonomoto K (2013) Improved lactic acid productivity by an open repeated batch fermentation system using Enterococcus mundtii QU 25. RSC Adv 3:8437–8445. https://doi.org/10.1039/C3RA00078H

Bhatt SM, Srivastava SK (2008) Lactic acid production from cane molasses by Lactobacillus delbrueckii NCIM 2025 in submerged condition: optimization of medium component by Taguchi DOE methodology. Food Biotechnol 22(2):115–139. https://doi.org/10.1080/08905430802043107

Shibata K, Flores DM, Kobayashi G, Sonomoto K (2007) Direct l-lactic acid fermentation with sago starch by a novel amylolytic lactic acid bacterium, Enterococcus faecium. Enzym Microb Technol 41:149–155. https://doi.org/10.1016/j.enzmictec.2006.12.020

Abdel-Rahman MA, Tashiro Y, Zendo T, Hanada K, Shibata K, Sonomoto K (2011) Efficient homofermentative l-(+)-lactic acid production from xylose by a novel lactic acid bacterium, Enterococcus mundtii QU 25. Appl Environ Microbiol 77:1892–1895. https://doi.org/10.1128/AEM.02076-10

Aboseidah AA, Rasmey AHM, Osman MM, Kamal N, Desouky SG (2017) Optimization of lactic acid production by a novel strain, Enterococcus faecalis KY072975 isolated from infants stool in Egypt. Eur J Biol Res 7:22–30. https://doi.org/10.5281/zenodo.242164

Vishnu C, Seenayya G, Reddy G (2002) Direct fermentation of various pure and crude starchy substrates to l-(+) lactic acid using Lactobacillus amylophilus GV6. World J Microbiol Biotechnol 18:429–433. https://doi.org/10.1023/A:1015526221744

Yu L, Lei T, Ren X, Pei X, Feng Y (2008) Response surface optimization of l-(+)-lactic acid production using corn steep liquor as an alternative nitrogen source by Lactobacillus rhamnosus CGMCC 1466. Biochem Eng J 39:496–502. https://doi.org/10.1016/j.bej.2007.11.008

Ponnusami V, Krithika V, Madhuram R, Srivastava SN (2007) Biosorption of reactive dye using acid-treated rice husk: factorial design analysis. J Hazard Mater 142(1–2):397–403. https://doi.org/10.1016/j.jhazmat.2006.08.040

Bingol D, Tekin N, Alkan M (2010) Brilliant yellow dye adsorption onto sepiolite using a full factorial design. Appl Clay Sci 50(3):315–321. https://doi.org/10.1016/j.clay.2010.08.015

Mladenović D, Pejin J, Kocić-Tanackov S, Djukić-Vuković A, Mojović L (2019) Enhanced lactic acid production by adaptive evolution of Lactobacillus paracasei on agro-industrial substrate. Appl Biochem Biotechnol 187:753–769. https://doi.org/10.1007/s12010-018-2852-x

Luongo V, Policastro G, Ghimire A, Pirozzi F, Fabbricino M (2019) Repeated-batch fermentation of cheese whey for semi-continuous lactic acid production using mixed cultures at uncontrolled pH. Sustainability 11:3330. https://doi.org/10.3390/su11123330

Xu K, Xu P (2014) Efficient production of l-lactic acid using co-feeding strategy based on cane molasses/glucose carbon sources. Bioresour Technol 153:23–29. https://doi.org/10.1016/j.biortech.2013.11.057

Wang Y, Li K, Huang F, Wang J, Zhao J, Zhao X, Garza E, Manow R, Grayburn S, Zhou S (2013) Engineering and adaptive evolution of Escherichia coli W for l-lactic acid fermentation from molasses and corn steep liquor without additional nutrients. Bioresour Technol 148:394–400. https://doi.org/10.1016/j.biortech.2013.08.114

Sun Y, Xu Z, Zheng Y, Zhou J, Xiu Z (2019) Efficient production of lactic acid from sugarcane molasses by a newly microbial consortium CEE-DL15. Process Biochem 81:132–138. https://doi.org/10.1016/j.procbio.2019.03.022

Acknowledgments

The authors are greatly thankful to Dr. Ehab F.S. Elbelely for his support and assistance with statistical analysis and great contribution in this work. We would like to thank the members of Fermentation Biotechnology and Applied Microbiology Centre, Al-Azhar University for their great support and contributions throughout this work

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

- Biorefinery of beet molasses to high lactic acid (LA) production by E. faecium S6 was established.

- EDTA, yeast extract, and ammonium chloride improved LA fermentation from molasses.

- OFAT optimization approach achieved 29.7 g/L of LA.

- RSM optimization approach enhanced LA production to 41.5 g/L.

- Integrated seed adaptation with increased molasses concentration in repeated batch fermentation was established.

- Sequential optimization of relevant factors achieved 64.7 g/L of LA.

Electronic supplementary material

ESM 1

(PPTX 1484 kb).

Rights and permissions

About this article

Cite this article

Alrefaey, H.M.A., Abdel-Rahman, M.A., Hassan, S.ED. et al. Sequential optimization of the fermentation factors with integrating seed culture adaptation for increased biorefinery of beet molasses to lactic acid. Biomass Conv. Bioref. 11, 1013–1028 (2021). https://doi.org/10.1007/s13399-020-00773-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00773-3