Abstract

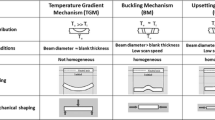

Laser forming (LF) is a new die-less forming technique that employs the energy from a laser beam to modify and adjust the curvature of sheet metals. In order to advance the LF process further for realistic application industry, it is necessary to consider large scale three-dimensional laser forming (3DLF). The main problem of 3DLF is the understanding of the mechanism and the planning of laser scanning strategy. This paper illustrates the temperature field, stress–strain field, and deformation field in the process of 3DLF of square sheet to spherical dome with spider-lines strategy with a finite element method (FEM). The explicit dynamic integral is used in the work presented in the paper rather than implicit method for improving the computational efficiency and accuracy. The FEM results showed that the inner stress induced by the laser beam propagates through the sheet as a stress wave, and the thermal stress and the stress wave in the sheet are the main influence factors in 3DLF. Also, the FEM results have been verified against experimental data, and a reasonable correlation has been found. The work showed in the paper would be beneficial of the parameter optimization of laser scanning strategy and the control of the formed precision of the sheet in 3DLF.

Similar content being viewed by others

References

Geiger M, Vollertsen F (1993) The mechanism of laser forming. Annals of the CIRP 42(1):301–304

Geiger M (1994) Synergy of laser material processing and metal forming. Annals of the CIRP 43(2):563–570

Edwardson SP (2004) A study into 2D and 3D laser forming of metallic components. Dissertation, The University of Liverpool

Edwards KR, Edwardson SP, Carey C, Dearden G, Watkins KG (2010) Laser micro peen forming without a tamping layer. Int J Adv Manuf Technol 47:191–200

Wenchuan L, Lawrence YY (2001) Laser forming with constant line energy. Int J Adv Manuf Technol 17:196–203

Hennige T (2000) Development of irradiation strategies for 3D-laser forming. J Mater Process Technol 103:102–108

Magee J, Watkins KG, Steen WM (1998) Advances in laser forming. J Laser Appl 10:235–246

Yang LJ, Wang Y, Djendel M, Qi LT (2004) Experimental investigation on 3D laser forming of metal sheet. Mater Sci Forum 471(472):568–572

Abed E, Edwardson SP, Dearden G, Watkins KG, McBride R, Hand DP, Jones JDC, Moore AJ (2005) Closed loop 3-dimensional laser forming of developable surfaces. International Workshop on Thermal Forming 13(14):1–21

Edwardson SP, Watkins KG, Dearden G, Magee J (2001) 3D laser forming of saddle shapes. In: Proceedings of laser assisted net shaping, Erlangen, Germany, pp 559–568

Edwardson SP, Moore AJ, Abed E, McBride R, French P, Hand DP, Dearden G, Jones JDC, Watkins KG (2004) Iterative 3D laser forming of continuous surfaces. In: Proceedings of the 23rd ICALEO, October 4–7, San Francisco, USA, pp 36–45

Hutterer A, Hagenah H (2004) Correcting non circular dents by means of laser beam forming. In: Proceedings of laser assisted net shaping. Erlangen, Germany, pp 1071–1081

Shimizu H (1997) A heating process algorithm for metal forming by a moving heat source, Dissertation, MIT

Cheng PJ, Lin SC (2000) An analytical model for the temperature field in the laser forming of sheet metal. J Mater Process Technol 101:260–267

Cheng JG, Yao YL (2004) Process synthesis of laser forming by genetic algorithms. Int J Mach Tools Manuf 44(15):1619–1628

Bao J, Yao YL (1999) Analysis and predication of edge effects in laser bending. In: Proceedings of ICALEO’99, San Diego, CA, pp 186–195

Li W, Yao YL (2000) Numerical and experimental study of strain rate effects in laser forming. J Manuf Sci Eng 122(3):445–451

Li W, Yao YL (2001) Numerical and experimental investigation of convex laser forming process. ASME J Manuf Process 3(2):73–81

Cheng J, Yao YL (2002) Microstructure integrated modeling of multi-scan laser forming. ASME Transactions, J Manuf Sci Eng 124(2):379–388

Liu C, Yao YL (2004) Optimal process planning for laser forming of doubly curved shapes. J Manuf Sci Eng 126:1–9

Na SJ, Kim JT (2008) 3D laser forming strategies for sheet metal by geometrical information. Int J Mater Form Suppl 1:1367–1370

Hu Z, Labudovic M, Wang H, Kovacevic R (2002) Computer simulation and experimental investigation of sheet metal bending using laser beam scanning. Int J Mach Tools Manuf 42(13):1427–1439

Yu G, Koichi Masubuchi, Takashi Maekawa, Nicholas M.Patrikalakis (1999) A finite element model for metal forming by laser line heating. In: Proceeding of the 10th international conference on computer application in shipbuilding (ICCAS’99), MIT, Cambridge, MA, vol 2, pp 409–418

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Wang, M., Wang, Y. et al. Dynamic analysis on laser forming of square metal sheet to spherical dome. Int J Adv Manuf Technol 51, 519–539 (2010). https://doi.org/10.1007/s00170-010-2636-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2636-0