Abstract

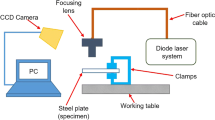

Laser forming is a thermal forming process, which uses laser beam irradiation to produce desired final forms. Initially, many researchers have investigated deeply in bending sheet metals using a straight scan pass. In this manuscript, a spider scanning strategy is considered to produce the dome-shaped aluminum sheet products. In this regard, laser forming process is investigated numerically and then some experiments are performed in order to validate the output results of numerical simulations. Full factorial design of experiments and analysis of variance are conducted to obtain an equation for predicting dome height of sheet metals. In addition, the effects of process parameters including laser power, scan velocity, beam diameter, and sheet thickness on dome height are studied. Moreover, the effects of heat flux, and line energy is investigated. The results show that with increasing laser power, line energy, and heat flux, dome height increases and with increasing beam diameter, sheet thickness, and scan velocity, dome height decreases notably. In addition, a final equation is presented which accurately predicts the dome height as a function of input process parameters.

Similar content being viewed by others

References

Liu J, Sun S, Guan Y, Ji Z (2010) Experimental study on negative laser bending process of steel foils. Opt Lasers Eng 48(1):83–88

Shi Y, Lu X, Yi P, Liu Z (2013) Effect of heating paths on strain distribution of plate in laser forming. Int J Adv Manuf Technol 66(1–4):515–521

Maji K, Pratihar D, Nath A (2012) Experimental investigations, modeling, and optimization of multi-scan laser forming of AISI 304 stainless steel sheet. The International Journal of Advanced Manufacturing Technology:1–15

Hennige T (2000) Development of irradiation strategies for 3D-laser forming. J Mater Process Technol 103(1):102–108

Kim J, Na SJ (2003) Development of irradiation strategies for free curve laser forming. Optics Laser Technol 35(8):605–611

Dearden G, Edwardson S (2003) Some recent developments in two-and three-dimensional laser forming for ‘macro’ and ‘micro’ applications. J Opt A Pure Appl Opt 5(4):S8

Yang LJ, Wang Y, Djendel M, Qi L Experimental investigation on 3D laser forming of metal sheet. In: Materials Science Forum, 2004. Trans Tech Publ, pp 568–572

Liu C, Yao YL, Srinivasan V (2004) Optimal process planning for laser forming of doubly curved shapes. J Manuf Sci Eng 126(1):1–9

Edwardson S, Abed E, French P, Dearden G, Watkins K, McBride R, Hand D, Jones J, Moore A (2005) Developments towards controlled three-dimensional laser forming of continuous surfaces. J Laser Appl 17(4):247–255

Kim J, Na SJ (2009) 3D laser-forming strategies for sheet metal by geometrical information. Optics Laser Technol 41(6):843–852

Liu C, Yao YL (2005) FEM-based process design for laser forming of doubly curved shapes. J Manuf Process 7(2):109–121

Venkadeshwaran K, Das S, Misra D (2010) Finite element simulation of 3-D laser forming by discrete section circle line heating. Int J Eng Sci Technol 2(4):163–175

Shekhar Chakraborty S, Racherla V, Kumar Nath A (2012) Parametric study on bending and thickening in laser forming of a bowl shaped surface. Opt Lasers Eng 50(11):1548–1558

Maji K, Pratihar DK, Nath AK (2014) Laser forming of a dome shaped surface: experimental investigations, statistical analysis and neural network modeling. Opt Lasers Eng 53:31–42

Gollo MH, Nadi G, Mehdi M, Abbaszadeh M (2015) Experimental and numerical study of spiral scan paths on cap laser forming. J Laser Appl 27(1):012002

Safari M, Farzin M (2015) Experimental investigation of laser forming of a saddle shape with spiral irradiating scheme. Optics Laser Technol 66:146–150

Chakraborty SS, More H, Nath AK (2016) Laser forming of a bowl shaped surface with a stationary laser beam. Opt Lasers Eng 77:126–136

Roohi AH, Naeini HM, Gollo MH, Soltanpour M, Abbaszadeh M (2015) On the random-based closed-cell metal foam modeling and its behavior in laser forming process. Optics Laser Technol 72:53–64

Hsieh H-S, Lin J (2004) Laser-induced vibration during pulsed laser forming. Optics Laser Techno 36(6):431–439

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shahabad, S.I., Naeini, H.M., Roohi, A.H. et al. Height prediction of dome-shaped products in laser forming process. Int J Adv Manuf Technol 88, 2227–2236 (2017). https://doi.org/10.1007/s00170-016-8946-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8946-0