Abstract

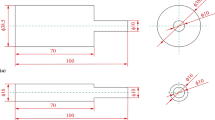

A model of direct-drive friction welding has been developed, which can be used to predict the time-temperature histories, the resultant microstructure, and the microhardness distribution across the weld interface of direct-drive friction-welded AISI/SAE 1045 steel bars. Experimentally measured power and axial displacement data were used in conjunction with a finite-element transient thermal model to predict the time-temperature history within the heat-affected zone (HAZ) of the weld. This was then used with a microstructure evolution model to predict the volume fraction of the subsequent microconstituents and the microhardness distribution across the weld interface of welds produced using three significantly different welding conditions: one with optimal conditions, one with a long burn-off time, and one with high axial pressure and rotational speed but short burn-off time. There was generally good agreement between the predicted and the measured time-temperature histories, volume fraction of the resultant microstructures, and microhardness distribution in the HAZ of AISI/SAE 1045 steel friction welds produced using these three significantly different welding conditions.

Similar content being viewed by others

References

G. Krauss: Steels — Heat Treatment and Processing Principles, 1st ed., ASM Int’l, Materials Park, OH, 1990.

V.I. Vill: Welding Production (translated from Russian), 1959, vol. 6, pp. 31–41.

G.J. Bendzsak and T.H. North: Trans. JWRI, 1996, vol. 25 (2), pp. 171–84.

N.N. Rykalin, A.I. Pugin, and V.A. Vasil’eva: Welding Production (translated from Russian), 1959, vol. 6, pp. 42–45.

Yu.D. Potapov, V.V. Trutnev, A. Yakushin, and A.P. Khokhabushin: Welding Production (translated from Russian), 1979, vol. 18 (2), pp. 1–3.

T. Rich and R. Roberts: Metal Construction and British Welding J., 1971, vol. 3 (3), pp. 93–98.

C.J. Cheng: Welding J., 1962, vol. 41 (12), pp. 542s-50s.

O.T. Midling and Ø. Grong: Acta Metall., 1994, vol. 42 (5), pp. 1594–609.

I.L.H. Hansson and J.K. Kristensen: Proc. Int. Conf. on Joining of Metals, O.A.K. Al-Erhayem, ed., Helsingφr, Denmark, 1984, pp. 161–67.

P.G. Bastien, J. Dollet, and Ph. Maynier: Metal Construction and British Welding J., 1970, vol. 2 (9), pp. 9–15.

Ph. Maynier, J. Dollet, and P.G. Bastien: Hardenability Concepts with Applications to Steel, D.V. Doane and J.S. Kirkaldy, ed., Metallurgical Society of AIME, New York, NY, 1978, pp. 163–76.

Ph. Maynier, B. Jungmann, and J. Dollet: Hardenability Concepts with Applications to Steel, D.V. Doane and J.S. Kirkaldy, ed., Metallurgical Society of AIME, New York, NY, 1978, pp. 518–44.

M.F. Ashby and K.E. Easterling: Acta Metall., 1982, vol. 30 (11), pp. 1969–78.

J.C. Ion, K.E. Easterling, and M.F. Ashby: Acta Metall., 1984, vol. 32 (11), pp. 1949–62.

J.S. Kirkaldy: Metall. Trans., 1973, vol. 4 (10), pp. 2327–33.

J.S. Kirkaldy and R.C. Sharma: Scripta Metall., 1982, vol. 16 (10), pp. 1193–98.

J.S. Kirkaldy and D. Venugopalan: Phase Transformation in Ferrous Alloys, A.R. Marder and J.I. Goldenstein, ed., Am. Inst. Min. Engrs., Philadelphia, PA, 1984, pp. 125–48.

T.C. Nguyen: M.A.Sc. Thesis, University of Waterloo, Waterloo, ON, Canada, 1997.

J. Huber: A.R.D. Industries Ltd., Cambridge, ON, Canada, private communication, 1996.

G.F. Vander Voort: Metallography Principles and Practice, ASM Int’l, Materials Park, OH, 1999.

F.P. Incropera and D.P. De Witt: Fundamentals of Heat and Mass Transfer, 3rd ed., John Wiley & Sons, Toronto, ON, 1990, p. 58.

R.D. Pelhlke, A. Jeyarajan, and H. Wada: Report No. NSF/MAE-82028, NSF Applied Research Division, University of Michigan, 1982.

D.F. Watt, L. Coon, M. Bibby, J. Goldak, and C. Henwood: Acta Metall., 1988, vol. 36 (11), pp. 3029–35.

K.H. Huebner and E.A. Thornton: The Finite Element Method for Engineers, 2nd ed., John Wiley and Sons, New York, NY, 1982.

S.C. Chapra and R.P. Canale: Numerical Methods for Engineers, 2nd ed., McGraw-Hill, Toronto, ON, 1988, pp. 261–69.

E112-88 ASTM Standard, Annual Book of ASTM Standards, Philadelphia, PA, 1994, vol. 03.01, pp. 227–52.

W.C. Leslie: The Physical Metallurgy of Steels, McGraw-Hill, New York, NY, 1981.

G.E. Linnert: Welding Metallurgy, 4th ed., American Welding Society, Miami, FL, 1994, vol. 1, p. 837.

L. Coon and D.F. Watt: Computer Modelling of Fabrication Processes and Constitutive Behaviour of Materials, J. Too, ed., Am. Inst. Min. Engrs., Philadelphia, PA, 1984, pp. 125–48.

C. Henwood, M. Bibby, J. Goldak, and D. Watt: Acta Metall., 1988, vol. 36 (11), pp. 3037–46.

B. Buchmayr and J.S. Kirkaldy: J. Heat Treat., 1990, vol. 8 (2), pp. 127–36.

Atlas of Time-Temperature Diagram for Irons and Steels, G.F. Voort, ed., ASM Int’l, Material Park, OH, 1991, p. 14.

I.F. Squires: British Welding J., 1966, vol. 13 (11), pp. 652–57.

H.M. Tensi, W. Welz, and M. Schwalm: Aluminium, 1982, vol. 58, pp. 515–18.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Nguyen, T.C., Weckman, D.C. A thermal and microstructure evolution model of direct-drive friction welding of plain carbon steel. Metall Mater Trans B 37, 275–292 (2006). https://doi.org/10.1007/BF02693157

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02693157