Abstract

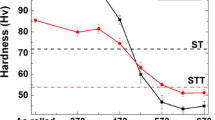

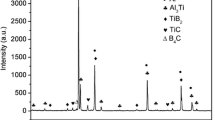

For A356 alloy, solidification with relative lower cooling rate will result in coarse grain size and lower mechanical properties. In this case, Al5Ti1B mater alloy was not the effective one to refine the A356 alloy. In present study, the effective grain refiner for A356 alloy was developed. Experimental results showed that the equiaxed grains were obtained with modified A356 alloy, rather than the dendritic grains of A356 refined by Al5Ti1B master alloy. Compared to the A356 alloy refined by 0.2 wt%Al5Ti1B, the yield strength, ultimate tensile strength and elongation of modified A356 alloy were increased by 4 MPa, 30.6 MPa, and 4.5% respectively. The value of yield strength, ultimate tensile strength and elongation of modified A356 alloy were 182.3 MPa, 278.3 MPa and 8.2%. The significant improvement of mechanical properties was ascribed to the effective nucleation of α-Al and the morphology evolution of eutectic Si.

Similar content being viewed by others

References

K.G. Basavakumar, P.G. Mukunda, M. Chakraborty, Influence of grain refinement and modification on microstructure and mechanical properties of Al–7Si and Al–7Si–2.5Cu cast alloys. Mater. Charact. 59, 283–289 (2008)

J. Wang, S. He, B. Sun, Q. Guo, M. Nishio, Grain refinement of Al–Si alloy (A356) by melt thermal treatment. J. Mater. Process. Technol. 141, 29–34 (2003)

C. Limmaneevichitr, W. Eidhed, Novel technique for grain refinement in aluminum casting by Al–Ti–B powder injection. Mater. Sci. Eng., A 355, 174–179 (2003)

B.J. McKay, Heterogeneous nucleation in Al–Si alloys. Ph.D thesis, University of Oxford (2001), pp. 95–98

S.A. Kori, B.S. Murty, M. Chakraborty, Development of an efficient grain refiner for Al–7Si alloy and its modification with strontium. Mater. Sci. Eng., A 283, 94–104 (2000)

A.L. Greer, A.M. Bunn, A. Tronche, P.V. Evans, D.J. Bristow, Modelling of inoculation of metallic melts: application to grain refinement of aluminium by Al–Ti–B. Acta Mater. 48, 2823–2835 (2000)

M. Easton, D. StJohn, Grain refinement of aluminum alloys: Part I. The nucleant and solute paradigms—a review of the literature. Metall. Mater. Trans. A 30A, 1613–1623 (1999)

A.M. Bunn, P. Schumacher, M.A. Kearns, C.B. Boothroyd, A.L. Greer, Grain refinement by Al–Ti–B alloys in aluminium melts: a study of the mechanisms of poisoning by zirconium. Mater. Sci. Technol. 15, 1115–1123 (1999)

A.M. Millis, R.F. Corchrane, Grain refinement and growth instability in undercooled alloys at low undercooling. J. Appl. Phys. 84, 1905–4910 (1998)

P.S. Mohanty, J.E. Gruzleski, Grain refinement mechanisms of hypoeutectic Al–Si alloys. Acta Mater. 44, 3749–3760 (1996)

Y.J. Zhang, H.W. Wang, N.H. Ma, X.F. Li, Effect of Fe on grain refining of pure aluminum refined by Al5TiB master alloy. Mater. Lett. 59, 3398–3401 (2005)

Y.J. Zhang, N.H. Ma, Y.K. Le, S.C. Li, H.W. Wang, Mechanical properties and damping capacity after grain refinement in A356 alloy. Mater. Lett. 59, 2174–2177 (2005)

X. Zhang, J. Sun, C. Zhou, Y. Zhang, N. Ma, H. Wang, Improvement of grain refinement efficiency in pure aluminum by embryos proliferation. Mater. Manuf. Process. 29, 826–831 (2014)

The Aluminium Association, Standard test procedure for aluminium alloy grain refiners (TP-1), Washington D. C. (1990)

Z. Fan, Y. Wang, Y. Zhang, T. Qin, X.R. Zhou, G.E. Thompson, T. Pennycook, T. Hashimoto, Grain refining mechanism in the Al/Al–Ti–B system. Acta Materailia 84, 292–304 (2015)

Y. Wang, H.T. Li, Z. Fan, Mechanisms of enhanced heterogeneous nucleation during solidification in binary Al–Mg alloys. Acta Materailia 60, 1528–1537 (2012)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Zhang, Y., Ji, S., Fan, Z. (2017). The Enhancement of Mechanical Properties of A356 Alloy Solidified at Lower Cooling Rate via Effectively Grain Refinement. In: Ratvik, A. (eds) Light Metals 2017. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-51541-0_30

Download citation

DOI: https://doi.org/10.1007/978-3-319-51541-0_30

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-51540-3

Online ISBN: 978-3-319-51541-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)