Abstract

To avoid brittle collapse of reinforced concrete (RC) structures, RC elements such as beams, columns, and shear walls are invited to ensure a minimum level of ductility. In this paper, an analytical method for predicting the curvature ductility factor of confined RC columns is developed. The stress–strain model of confined concrete provided by Eurocode 2 is adopted, and the effective lateral confining pressure is calculated according to the Eurocode 8. The curvature ductility factor is defined by the ratio of ultimate to yield curvature. In this context, a new hypothesis is adopted to calculate the yield curvature while the ultimate curvature is calculated based on axial load and the mechanical ratios of tension, web, and compression reinforcement. The results showed that the developed method has an excellent performance compared to the experimental results collected from previous researches, where the mean value and the standard deviation of the ratios predicted to experimental factors are equal to 1.02 and 0.17, respectively. Moreover, the calculated coefficient of determination is very close to 1.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Ductility is a vital parameter in seismic design. The ductility of reinforced concrete (RC) structure depends on the ductility of its elements such as columns. In addition to their great potential in restoring the load-bearing capacity, high ductile RC columns provide adequate ductility to the overall structure [1]. From here, it appears the great importance of RC columns ductility. In this field, the study of RC columns ductility requires a deep analysis at the limit states, where it is essential to know the behavior of materials such as concrete and steel [2]. Practically, the RC column cross section is subjected to lateral pressure resulted from the transverse reinforcement, named confinement [3, 4]. Under confinement, significant enhancements are occurred on concrete behavior, where higher strength and higher critical strains are achieved [5, 6]. These changes on concrete characteristics affect the overall behavior of RC elements, so it is necessary to take into account these new characteristics in structural elements studying [7].

Most of the research carried out on the flexural behavior of RC columns are experimental works, where the curvature ductility factor was obtained from the moment–curvature (M–φ) diagram. The yield curvature was measured when the tension reinforcement yielded in tension while the ultimate curvature was measured when the concrete strain reaches its ultimate value. In this field, experimental researches proved that the increase of lateral pressure enhances the curvature ductility of RC columns [8, 9].

On the other hand, a few theoretical researches were conducted on the curvature ductility of RC columns. The lack of theoretical researches in this field pushed the researchers to undertake the current study. A new hypothesis is introduced in order to calculate the yield curvature while the ultimate curvature is calculated according to the proposition of Fardis [10]. In this context, the model of confined concrete given by Eurocode 2 [5] is adopted for the present study. Finally, experimental data are collected in order to show the reliability of the developed model in predicting the curvature ductility factor of confined RC columns made with normal strength (NSC) and high strength concrete (HSC).

2 Stress–Strain Relationship for Confined Concrete Under Compression

Similar to unconfined concrete, Eurocode 2 [5] provides a parabola-rectangle diagram for confined concrete under compression as shown in Fig. 1. Compared to unconfined concrete, an increase in stress (σc) and strain (εc) can be noticed. This amelioration is due to the effective lateral confining pressure (σ2).

Stress–strain (σc–εc) model for confined concrete [5]

The compressive strength of confined concrete (fcc) is given by the following expression:

where fʹc = compressive strength of unconfined concrete.

The strains at reaching the maximum strength (ε0c) and at ultimate (εcuc) are given as follows:

where ε0 and εcu = strains at reaching the maximum strength and at ultimate of unconfined concrete, respectively.

On the other hand, the effective lateral confining pressure (σ2) is calculated as follows:

where ωwd = mechanical volumetric ratio of confining hoops within the critical region and α = confinement effectiveness factor. These two parameters can be calculated according to Sect. 5.4.3.2.2 of Eurocode 8 [11].

3 Curvature Ductility Factor

The curvature ductility factor (μφ) is calculated by dividing the ultimate curvature (φu) by the curvature at yielding (φy):

3.1 Curvature at Yielding

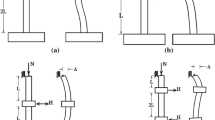

The yield curvature (φy) is calculated when the tension reinforcement reaches their yield strength. As shown in Fig. 2b, the web reinforcement (Asw) creates a rigid region in the middle of the column cross section, where they prevent the increase of the tension region depth. In this context, the neutral axis depth (kd) is assumed to be greater than (h/2), where it is taken as follows:

Hence, the yield curvature is written as follows:

where h = height of column cross section; lsv = length of the rigid region created by web reinforcement; εsy = fy/Es = strain corresponding to yield strength of steel reinforcement; d = distance measured from the extreme compression fiber to the centroid of the tension reinforcement; fy and Es = yield strength and modulus of elasticity of tension steel reinforcement; b = width of column cross section; d1 = distance measured from the extreme compression fiber to the centroid of the compression reinforcement; As, Aʹs and Asw = areas of tension, compression, and web reinforcement.

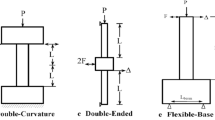

3.2 Curvature at Ultimate

The ultimate curvature is calculated when the strain in the extreme compression fiber of the confined zone reaches the ultimate value (εcuc). Figure 3 shows the strain distribution at this stage. Based on this figure, the ultimate curvature is written as follows:

where c = neutral axis depth at ultimate and e = distance measured from extreme compression fiber of concrete to confined zone extremity.

In this case, the neutral axis depth (c) was given by Fardis [10] as follows:

where

-

δ1 = d1/d

-

ν = N/b0 d0 fcc: ratio of the axial load (N)

-

ωs = Asfy/b0 d0 fcc, ωʹs = Aʹsfy/b0 d0 fcc, ωsw = Aswfy/b0 d0 fcc: mechanical reinforcement ratios of tension, compression, and web reinforcement, respectively

-

h0 = h − 2(e0 + dbh/2), b0 = b − 2(e0 + dbh/2), d0 = d − 2(e0 + dbh/2)

-

dbh: diameter of transverse reinforcement

-

e0: concrete cover.

4 Method Verification

In this section, the performance of the presented method is tested against large experimental results collected from the literature. In this field, 30 experimentally tested columns are selected from previous researches. The details and properties of the selected specimens are shown in Table 1.

The predicted curvature ductility factors (μφ,pre) of the selected specimens are presented in Table 2 with those obtained during experiments (μφ,exp). The comparison shows a good agreement between the predicted and the experimental values, where the mean value (MV) and the standard deviation (SD) of the errors (μφ,pre/μφ,exp) are equal to 1.02 and 0.17, respectively. In the same context, Fig. 4 shows the predicted and the experimental results head-on. The dispersion of the points affirms the good agreement between the predicted and the experimental results. Moreover, the value of the coefficient of determination (R2 = 0.90) confirms this deduction, where it is very close to 1. Consequently, these statistical results indicate the good performance of the proposed method in predicting the curvature ductility factor of NSC and HSC columns.

5 Conclusion

The current research presented a detailed method in order to predict the curvature ductility factor of confined RC columns made with NSC and HSC. Eurocode 2 [5] and Eurocode 8 [11] were used to calculate the strength and strains of concrete under confinement, i.e., under lateral pressure due to transverse reinforcement. In this field, the results obtained by using the proposed method were compared with those extracted from experimental researches. The statistical comparison showed that the proposed method has a good performance and accuracy in predicting the curvature ductility factor of confined RC columns with concrete strength up to 100 MPa.

On the one hand, the present study provided a simple method that can be used with high accuracy. On the other hand, it can be a starting point for studying the ductility of RC columns confined with other types of materials or under active confinement. Moreover, it motivates researchers to undertake other studies on different confined RC elements such as beams.

References

Polienko W, Holschemacher K, Henning VD (2022) Column confinement with textile-reinforced concrete (TRC). In: Proceedings of the fourth European and Mediterranean structural engineering and construction conference. ISEC Press, Leipzig, Germany

Bouzid H, Kassoul A (2018) Curvature ductility prediction of high strength concrete beams. Struct Eng Mech 66(2):195–201

Biskinis DE (2007) Resistance and deformation capacity of concrete members with or without retrofitting. Doctoral thesis, Civil Engineering Department, University of Patras, Patras, GR

Guadagnuolo M, Alfonso D, Anna T, Giuseppe F (2020) Experimental behavior of concrete columns confined by transverse reinforcement with different details. Open Constr Build Technol J 14:250–265

Eurocode 2, EN 1992-1-1 (2003) Design of concrete structures. Part 1-1: General rules and rules for buildings. European Committee for Standardization. Brussels, Belgium

Halima A, Kassoul A, Bouzid H (2019) New model for confinement of reinforced concrete columns with an ultra-high strength close to 200 MPa. Eng Struct 199:109594

Breccolotti M, Annibale LM, Bruno RB (2019) Curvature ductility of biaxially loaded reinforced concrete short columns. Eng Struct 200:109669

Pam HJ, Ho JCM (2009) Length of critical region for confinement steel in limited ductility high-strength reinforced concrete columns. Eng Struct 31:2896–2908

Karen ECM, Bonet JL, Juan NG, Pedro SR (2013) An experimental study of steel fiber-reinforced high-strength concrete slender columns under cyclic loading. Eng Struct 57:565–577

Fardis MN (2009) Seismic design, assessment and retrofitting of concrete buildings: based on EN-Eurocode8. Springer Science + Business Media B.V., New York

Eurocode 8, EN 1998-1 (2003) Design of structures for earthquake resistance. Part 1: General rules, seismic actions and rules for buildings, Brussels, Belgium

Sheikh SA, Yeh CC (1990) Tied concrete columns under axial load and flexure. J Struct Eng 116(10):2780–2800

Sheikh SA, Khoury SS (1993) Confined concrete columns with stubs. ACI Struct J 90(4):90-S44

Sheikh SA, Shah DV, Khoury SS (1994) Confinement of high strength columns. ACI Struct J 91(1):91-S11

Ho JCM, Pam HJ (2003) Inelastic design of low-axially loaded high-strength reinforced concrete columns. Eng Struct 25:1083–1096

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Bouzid, H., Rabia, B., Daouadji, T.H. (2023). Curvature Ductility of Confined HSC Columns. In: Wang, S., Li, J., Hu, K., Bao, X. (eds) Proceedings of the 2nd International Conference on Innovative Solutions in Hydropower Engineering and Civil Engineering. HECE 2022. Lecture Notes in Civil Engineering, vol 235. Springer, Singapore. https://doi.org/10.1007/978-981-99-1748-8_21

Download citation

DOI: https://doi.org/10.1007/978-981-99-1748-8_21

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-1747-1

Online ISBN: 978-981-99-1748-8

eBook Packages: EngineeringEngineering (R0)