Abstract

Ductility of high-strength concrete (HSC) columns with rectangular sections was assessed in this study by reviewing experimental data from the available literature. Up to 112 normal weights concrete columns with strength in the range of 50–130 MPa were considered and presented as a database. The data included the results of column testes under axial and reversed lateral loading. Displacement ductility of HSC columns was evaluated in terms of their concrete and reinforcement strengths, bar arrangement, volumetric ratio of transverse reinforcement, and axial loading. The results indicated that the confinement requirements and displacement ductility in HSC columns are more sensitive than those in normal strength concrete columns. Moreover, ductility is descended by increasing concrete strength. However, it was possible to obtain ductile behavior in HSC columns through proper confinement. Furthermore, this study casts doubt about capability of P/A g f c′ ratio that being inversely proportional to displacement ductility of HSC columns.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ductility and inelastic deformability of reinforced concrete columns are essential for overall strength and stability of structures during a strong earthquake. Ductility of columns can be achieved through proper confinement of core concrete. In the current design of building codes, the requirements for confinement steel have been outlined, but most of these requirements are intended for columns with normal strength concrete, where specified compressive strength does not usually exceed 40 MPa.

In the last decades, strengths of concrete much higher than 50 MPa have gained acceptance in the construction industry. Strengths of concrete up to 130 MPa have been used successfully in building and bridge construction, where according to the publication of ACI-363 (2010), they have economic advantages. Furthermore Ramezanianpour (2014) explains using high-performance concrete (HPC) and high-strength concrete (HSC) have more beneficial effects for sustainable development.

Although HSC has gained acceptance in practice and some special publication and reports like ACI-SP293 (2013), ACI-363 (2010) and fib bulletin 42 (2008) have been supported this technology, the application of HSC in high seismic regions has lagged behind its application in the low seismicity region. For instance, before the publication of ACI318-2014, the issues related to HSC columns including their strength and ductility were not addressed appropriately, whereas state of the art of HSC was reported by joint ACI-ASCE Committee 441 in 1996. Anyway, strength and ductility of HSC columns is one area where little design information is available for practicing engineers.

Before the current century, ductility of HSC column with steel reinforcement had been examined by some researchers such as; Chung et al. (1980), Watanabe et al. (1987), Muguruma et al. (1990), Mugurumu (1991), Sugano et al. (1990), Sakai (1990), Kabeyasawa et al. (1990, 1991), Thomsen and Wallace (1992), Azizinamini et al. (1994), Ghosh et al. (1998) and Kato et al.(1998). Furthermore, contemporary investigators have continued this topic such as; Sharma and Bhargava (2005), Ishikawa et al. (2008), Elwood et al. (2009a, b), Murthy et al. (2013), Kimura et al. (2013), Zhu et al. (2016), Jin et al. (2016), Ding et al. (2017), and Gaitan (2017).

This paper evaluates the displacement ductility of HSC columns based on existing experimental data in terms of concrete strength, confinement steel strength, longitudinal bar arrangement, volumetric ratio of transverse reinforcement, and axial loading. Furthermore, it presents critical factors in the displacement ductility assessment of HSC columns based on the outcomes of a research project in which a literature review was conducted on experimental data due to lateral load reversal loading for concrete with compressive strengths approximately more than 50 MPa and up to 130 MPa. The correlation between confinement parameters and column displacement ductility are illustrated as well.

Column tests considered

Although ACI-318 (2014) has some special requirements for concrete columns with specified compressive strength exceeding 70 MPa, normal weight concrete with strength higher than 50 MPa is generally referred to as HSC. ACI-363 (2010) and CSA-A23.3 (2014) consider HSC as concrete with 28-day cylinder strength higher than 55 and 50 MPa, respectively. It is defensible, because to produce and test of this kind of concrete special care is required. Furthermore, since the strength of most ready-mix concrete supplied, and strength of most concrete used in experimental researches were limited to 40 MPa, which provided the source for the majority of the building code provisions, the strength exceed more than 50 MPa is the adequate bound for HSC. Therefore, the experiments evaluated in this paper include reinforced concrete columns with normal weight aggregate having specified compressive strength of concrete with the range of 50–130 MPa.

There are not many experiments of HSC columns under lateral reversed cyclic loading in the literature. Up to 112 HSC column tests with square sections under combined axial force and lateral loading reversals have been evaluated in this study. The columns were tested under axial force along with unidirectional bending and shear force reversals. As illustrated in Fig. 1, mainly four types of column specimens were tested in the experimental investigations, commonly a vertical ram was used to apply a constant axial compression load, and one or two horizontal jacks or actuators were used to apply the lateral reversed cyclic load or displacement. Sezen (2002) presented four kind of setup that we adopt them and introduce in Fig. 1, but in this investigation only three of them were found in literature, so the type D is not used in this paper.

Column Test Configuration—Adapted from Sezen (2002). a Double curvature specimen (Setup Type A), b Cantilever specimen (Setup Type B), c Specimen with single stub (Setup Type C), d Specimen with Double stub (Setup Type D)

According to loading protocol of each experiment, firstly, it was attempted to apply a constant axial load, then lateral loading/displacement sequence were applied. This Lateral loading/displacement sequence was repeated cycles of stepwise increasing amplitudes, so it had several steps. Each step included a number of cycles. The oscillation amplitude in the first step was chosen since the specimen remains in the elastic range and it was incrementally increased to a certain extent, leading to the deterioration or failure of the specimen. See Fig. 2.

The geometry of column sections includes square and rectangular shapes with different types of confinement steel, including circular and square spirals, and a large number of different arrangements of ties. Figure 3 shows the types of reinforcement arrangements.

Cross-sectional dimensions for square columns ranged between 150 and 600 mm. The rectangular columns had a 200 by 150 mm cross section. Concrete strengths with up to 130 MPa were used. The main variables considered were concrete strength, level of axial load, reinforcement arrangement, volumetric ratio and strength of tie reinforcement. Table 1 shows the highlights of research programs on the HSC column experiments under lateral load reversals and their main parameters. Table 2 shows a summary of the variables.

Analysis of test data

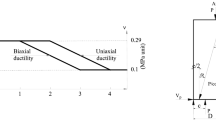

Ductility of columns subjected to lateral deformation cycles was evaluated in terms of displacement ductility and drift ratios. As Park (1989) has described, there are alternative definitions for ductility ratio. The displacement ductility ratio is defined as the ratio of maximum displacement recorded prior to exceeding 20% strength decay under cyclic loading, to the yield displacement. Figure 4 depicts the definition of the displacement ductility ratio and equation number one may derive it. This definition is the same as the one used previously by Saatcioglu (1991) in evaluating ductility of normal strength concrete columns or by Razvi and Saatcioglu (1994) in measuring ductility of HSC columns.

To achieve the points of equivalent yield displacement, first, two horizontal lines H u and 0.75H u , are drawn, see Fig. 3. Then, a continuous line from origin to meet point of the 0.75H u line and curve up to the H u line is drawn. Projection of the last meet point on horizontal axis is an equivalent point of yield displacement that is shown by \(\Delta_{y}\). Finally, project the meet point of 0.8H u line and original curve on horizontal axis to get ultimate displacement.

Consequently, the drift ratio is found by dividing the same maximum recorded displacement by the free length column, (Δ u ,/L′). The displacements are caused by cyclic loading where at least two cycles of deformation are imposed on the member at each deformation level. The deformations are increased incrementally, where each increment is less than twice the yield displacement, which is a standard loading protocol as described by Park (1989) and recommended by FEMA-461 (2007). Table 3 presents ductility and drift ratios obtained from the evaluation of 112 column specimens, as well as equivalent yield and ultimate displacement.

Investigation of experiment data indicates that HSC column ductility is a function of three groups of parameters, as ACI-ASCE Committee 441 (ACI-ASCE 2010) and Razvi and Saatcioglu (1994) described: (1) Those related to applied loading, (2) Those related to confinement reinforcement, and (3) Those related to concrete type. The significance of each of these groups of parameters is assessed separately in these pair reviews. Approach of this paper is similar to the mentioned ones, but it maintains its own attitude and uses more new data and records.

Effect of concrete compressive strength and axial load on ductility

Figure 5 displays variation of displacement ductility (\(\mu_{\Delta }\)) versus concrete strength for three kinds of column test setup that Fig. 1 depicts their configurations. This Figure indicates an increase in concrete compressive strength, tending to lower ductility in all kinds of column test configurations. This effect casts doubt about capability of P/A g f c′ ratio being inversely proportional to HSC columns ductility ratio. Indeed, increasing f c′ will reduce the value of this ratio, where according to other studies like Sheikh and Yeh (1990) or Shiekh and Khoury (1993), ductility of column will decrease by increasing P/A g f c′ ratio and it is absolutely conflicting with the result depicted in Fig. 5, which shows reduction in HSC column ductility by increasing the concrete strength. This concern becomes more challenging in the ASCE 41 (2013), where a larger range of modeling parameters for the nonlinear structural analysis of columns for smaller P/A g f c′ ratios is observed.

In addition, when variation of ductility is displayed versus P/A g f c′, a kind of scatter of data is found. Figures 6, 7 and 8 depict these variations for three column test configurations (Setup Type) and 14 major steel confinement configurations (Section Type) previously displayed in Figs. 1 and 3. Although, in some instances the trends are descending, for some other major instances are ascending, like Section Type 3, 4, 5 and 8 in Setup Type B and Section Type 3 and 7 in Setup Type C. Hence, it is not possible to conclude when P/A g f c′ ratio increases, the displacement ductility of HSC column decreases or not.

Parameters related to confinement

Passive confinement pressure is directly related to volumetric ratio of confinement steel that can be applied by bars and ties. Increase in the volumetric ratio of a specific grade of steel directly translates into a proportional increase in the confinement pressure. Therefore, both strength and ductility of confined concrete are increased. According to Table 3, it is obvious that displacement ductility increases by increasing volumetric ratio of confinement steel. However, some cases do not obey this rule; these exceptions occurred due to change in other parameters. Therefore, confinement steel was studied further along with transverse reinforcement spacing, concrete compression strength, and strength of confinement reinforcement, which is discussed in the following section.

Strength of confinement bars

Confinement pressure is generated from tensile forces developed in confinement steel. It is, therefore, likely to expect that the steel yield strength plays an important role in concrete confinement. However, tensile stress in confinement steels is created as an outcome of lateral expansion of concrete, which in turn is dependent on the mechanical properties of concrete. If the lateral strain in concrete is not high enough to impose higher stresses on transverse reinforcement, a high capacity of steel may not be utilized.

The previous research indicates conflicting views on the use of high-strength steel as confinement reinforcement. However, by referring to Mugurumu (1991) and Azizinamini et al. (1994), it seems that high yield strength transverse reinforcement (yield strength exceeding 750 MPa) has been shown to be advantageous when the level of axial loads is high (above 40% of column axial load capacity). When the level of axial load is relatively low (less than or equal to 20% of axial load capacity), the use of higher yield strength steel for transverse reinforcement may not result in any improvement in the strength and ductility of HSC columns.

Table 4 shows the results of four test columns that can compare the effect of yield strength of transverse reinforcement on the ductility of HSC columns. All four specimens were subjected to constant axial load levels equivalent to 17% of the column capacity, and repeated lateral loads and all of them had approximately the same concrete strength. However, the steel yield strength of lateral reinforcement is classified at two levels of normal strength (#44 and #45 specimens) and high strength (#46 and #47 specimens). On the other hand, the volumetric reinforcement ratio for specimen numbers 44 and 46 is 2.73 and 2.36%, respectively, and for specimen numbers 45 and 47 is 3.82%. As it is observed, although the steel yield strength of lateral reinforcement increases approximately 50%, the displacement ductility and drift ratio of these specimens do not change significantly and even for specimen number 47, displacement ductility is less than specimen number 45.

A justification of this condition is due to low limit of axial compression loading, and the tension stress of lateral reinforced does not reach the yield point and thus confinement stress for both couple specimens are the same so that displacement ductility values are approximately near to each other. This result indicates that increasing the yield strength of the transverse reinforcement has no influence on the ductility capacity of HSC columns at relatively low axial load levels. However, on the other hand, when axial loading is growing, some differences in comparing ductility are exposed. As Table 5 shows, the displacement ductility of columns increased by rising yield strength of the transverse reinforcement when ratio of axial compression loading was above 40% of column axial load capacity.

Confinement pressure is a passive pressure activated by lateral expansion of concrete under axial compression. This pressure is dependent on the ability of concrete to expand laterally prior to failure. In addition, the strength of lateral steel limits the confinement pressure. If the transverse strain of HSC is not high enough to pull the confinement steel to its capacity, then the full capacity of steel is not utilized. On the other side, HSC is a brittle material and may not develop transverse expansion high enough to pull the steel to its yield level. However, it is expected when the confinement steel develops its strength prior to concrete strength decay, since in this case, the tensile force in the confinement steel is directly related to the amount as well as the yield strength of steel.

When the amount of confinement steels are too much, the column’s ductility may decrease as presented in Table 6. As it is seen, ductility of specimen number 85 significantly falls; however, it has the highest volumetric ratio. It seems, when amount of steels are too much, the cohesion and bonds of steel and concrete are not appropriate, and before confinement steel reach to its maximum strength concrete column core would be crushed.

Transverse reinforcement spacing

The spacing of lateral reinforcement is a significant factor affecting the distribution of confinement pressure as well as stability of longitudinal reinforcement. Closer spacing of transverse reinforcement raises uniformity of lateral pressure and improves effectiveness of confinement reinforcement, having optimistic effects on the ductility of HSC columns. Cusson and Paultre (1994) observed that decrease in tie spacing outcome in better strength and stiffness. Al-Hussaini et al. (1993) observed that reducing the tie spacing from 0.8 to 0.2 times the column dimension increased strength (P/A g f c′) by only 6%. Sudo et al. (1993) concluded that reduction in spiral pitch outcome in increases in strength and the corresponding strain, and improved the descending branch of the stress–strain correlation of confined concrete.

The results point to improvement in ductility with reduction in lateral spacing. However, the spacing alone cannot affect the confinement mechanism, unless the other positive confinement factors are available. For instance, the volumetric ratio and/or yield strength of steel must be sufficiently high for spacing to make a difference in the confinement. Table 7 shows the effect of spacing of transverse reinforcement on the displacement ductility ratio adapted from studies conducted by Woods et al. (2007) and Hwang et al. (2005), which indicated that with invariable of other parameters, the higher ductility occurred by lower spacing of lateral reinforcement.

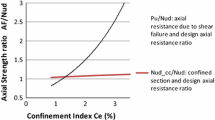

The improvement associated with the use of high-strength confinement steel is more pronounced in columns with higher volumetric ratio of transverse steel and lower strength of concrete. It is expected, since the tensile force in confinement steel is directly proportional to the amount and the yield strength of steel, a higher strength concrete would require higher confinement pressure. Therefore, the test data are also evaluated using a non-dimensional ratio.

Sugano et al. (1990) as well as Razvi and Saatcioglu (1994), Saatcioglu and Razvi (1993) reported a correlation between the non-dimensional parameter of confinement ratio, \(\rho_{\text{s}} f_{\text{yt}} /f_{\text{c}}^{{\prime }}\) and axial deformability of HSC columns subjected to concentric loads. Razvi and Saatcioglu (1994) in their study concluded that in all cases, axial deformability under compression loading increases with increase of \(\rho_{\text{s}} f_{\text{yt}} /f_{\text{c}}^{{\prime }}\) ratio. Furthermore, the study includes comparisons of columns made with distinctly different strength concretes with approximately the same ρ s f yt/f c′ ratios. The comparison indicates that column deformability remains essentially unchanged when the \(\rho_{\text{s}} f_{\text{yt}} /f_{\text{c}}^{{\prime }}\) ratio is maintained, irrespective of concrete strength. However, it is important to notice that for compared specimens, comparable reinforcement arrangements, tie spacing, and axial load levels were employed.

Razvi and Saatcioglu (1994) reported the relationship between concrete strength, confinement steel strengths and the volumetric ratio of transverse reinforcement. Sugano et al. (1990) stated that the product ρ s f yt be increased in proportion to concrete strength. They recommended that the ρ s f yt/f c′ ratio should be at least 0.2 to obtain ductile behavior. Nagashima et al. (1992) reported that 120 MPa concrete columns showed a sudden drop in strength at a strain of approximately 1% when ρ s f yt/f c′ was less than 18 MPa (ρ s f yt/f c′ ratio less than 0.15), and developed strains in excess of 2% when this product was higher than 18 MPa (ρ s f yt/f c′ ratio greater than 0.15). The same research program reported that the minimum value of 9 MPa for ρ s f yt produced satisfactory performance for columns with 60 MPa concrete. Hatanaka and Tanigawa (1992) showed that the ρ s f yt/f c′ ratio must be kept constant to maintain the same ductility for normal strength and HSC columns. Nishiyama et al. (1993) reported that a 4% volumetric ratio of 800 MPa confinement steel was required to obtain ductile columns when concrete strength was 110 MPa (i.e. ρ s f yt/f c′ = 29%).

Review of additional test data, where the volumetric ratio of steel for HSC was lower or equal to that of the companion lower strength concrete column, does not necessarily show the same trend. This indicates that the reduction in concrete deformability due to increased strength may be offset by increasing the volumetric ratio, ρ s, and steel yield strength, f yt, such that the product ρ s f yt is increased in proportion to the increase in concrete strength. Further research is needed to confirm this point.

It is highly important to notice in review of the literature that only correlation between the non-dimensional parameter of confinement ratio,\(\rho_{\text{s}} f_{\text{yt}} /f_{\text{c}}^{{\prime }}\) and axial deformability of HSC columns subjected to concentric loads has been found and there is not a comprehensive investigation to develop a correlation between \(\rho_{\text{s}} f_{\text{yt}} /f_{\text{c}}^{{\prime }}\) and displacement ductility, \(\mu_{\Delta }\). However, Razvi and Saatcioglu (1994) indicated a similar result like what was explained concerning axial deformability.

Table 3 illustrates variation of displacement ductility,\(\mu_{\Delta }\), with the confinement ratio, \(\rho_{\text{s}} f_{\text{yt}} /f_{\text{c}}^{{\prime }}\). In view of this study, for all kinds of column test configurations (setup types in Fig. 1), the general trend of displacement ductility is ascending versus the confinement ratio. See Fig. 9.

Tie arrangement

Arrangement of reinforcement is another parameter affecting the distribution of confinement pressure. If the lateral force applied by transverse reinforcement on concrete is well distributed around the perimeter of the core concrete, the distribution of lateral pressure becomes almost uniform, improving the effectiveness of confinement reinforcement. Some researches such as Mander et al. (1988), and Saatcioglu and Razvi (1992) have shown that the arrangement of transverse reinforcement has major effects on strength and ductility of normal strength concrete columns. In addition, other researchers like Yong et al. (1988), Sakai (1990), and Saatcioglu and Razvi (1993) observed the same effect. The results indicate that HSC columns, reinforced with well-distributed and laterally supported longitudinal reinforcement, exhibit improved ductility. Nagashima et al. (1992) observed, however, that columns with six, eight, and 12 longitudinal bar arrangements (Steel Confinement Configuration type 2, 3 and 6—see Fig. 3) did not exhibit a significant difference in strength and ductility. Cusson and Paultre (1994) concluded that columns with 12 longitudinal bar arrangements (Type 6 in Fig. 3) did not necessarily show improved behavior over those with an 8-bar arrangement (Type 3 in Fig. 3).

Amount, spacing and strength of longitudinal bar

The effect of longitudinal bars, in terms of bar size and steel grade, has been studied experimentally. Sakai (1990) reported that columns with a higher percentage of longitudinal steel showed improved ductility. Cusson and Paultre (1994) concluded that the beneficial effects of high reinforcement ratio of longitudinal steel increased with the degree of confinement provided by other parameters. On the other hand, Bjerkeli et al. (1990) showed that there was no significant effect of longitudinal steel ratio on the stress–strain relationship of confined concrete in columns with 1.4–3.6% steel ratios. Nagashima et al. (1992) showed that the grade of longitudinal reinforcement did not affect the stress–strain relationship of confined concrete.

It is important to notice all these researches investigated the axial deformability of columns regardless of their lateral loading. According to this investigation (Tables 2, 3), displacement ductility, and drift ratio increased by increasing the amount and strength of longitudinal bars. Furthermore, longitudinal bar spacing as parameter s 1 , is another factor affecting the distribution of confinement pressure. If the lateral force applied by longitudinal reinforcement on concrete is well distributed around the boundary of the core concrete, the distribution of lateral pressure becomes almost uniform, improving the effectiveness of confinement reinforcement.

Section geometry and size

It has been well established that circular spirals are more effective in confining concrete than rectilinear ties. The advantage of circular spirals owes to their geometric shape, producing unvarying and unbroken pressure around the border of the core. According to Saatcioglu and Razvi (1992), rectilinear ties can not produce uniform pressure, peaking at positions of transverse legs of tie steel. Hatanaka and Tanigawa (1992) reported that the lateral pressure created by a square perimeter tie was approximately 0.3–0.5 times of the pressure provided by a circular tie. Ekasit (1993) reported that strain measured in a spirally reinforced circular column was 12% higher than that measured in a companion tied column at the same stress level.

Most of the HSC column tests reported in the literature are small-scale specimens. A relative research carried out by Martinez et al. (1982) that explained lower strength in smaller specimens in comparison to larger specimens, representing the size effect. However, because of the limited nature of the available experimental data, it is difficult to generalize this conclusion.

Conclusions

This investigation collected some main information on the ductility of 112 normal weight concrete columns with specified compressive strength in the range of 50–130 MPa and presented a novel database. The data included the results of column testes under axial and reversed lateral loading. Moreover, HSC columns were evaluated in terms of their concrete and reinforcement strengths, bar arrangements, tie spacing, axial load ratio, ductility, and drift ratio. Therefore, the following conclusions are presented:

-

1.

In HSC columns, an increase in the specified compressive strength of concrete tends to result in lower displacement ductility.

-

2.

Review of statistics casts doubt about capability of P/A g f c′ ratio being inversely proportional to HSC columns displacement ductility ratio. Indeed, increasing concrete strength will reduce the \(P/A_{\text{g}} f_{\text{c}}^{{\prime }}\) ratio and according to other studies and codes, ductility of columns will be increased by reducing \(P/A_{\text{g}} f_{\text{c}}^{{\prime }}\) ratio. Hence, codes and standard should be more concern about range of modeling parameters for nonlinear analysis of concrete structures with HSC columns and therefore more studies are needed.

-

3.

To reach the appropriate ductility, HSC columns should be confined properly. The main parameters of confinement include volumetric ratio, bar spacing, arrangement of reinforcement, and strength of transverse reinforcement. Regardless of the effect of axial load, bars arrangement and lateral reinforcement spacing, the general trend of displacement ductility, μ Δ, versus non-dimensional parameter, \(\rho_{\text{s}} f_{\text{yt}} /f_{\text{c}}^{{\prime }}\), is ascending.

-

4.

If the potential lateral dilation of concrete is not high enough to impose higher stresses in confinement steel to its capacity, higher capacity of steel may not be utilized. Furthermore, HSC is a brittle material and may not develop transverse dilation high enough to strain the steel to its yield level. In this case, before confinement steel reaches to its appropriate strength, concrete column core would be crushed. Therefore, more confinement is required to reach the appropriate ductility. Moreover, review of literature shows that reducing the bar spacing is more useful than other confinement parameters.

Abbreviations

- A g :

-

Gross cross-sectional area of column

- A s :

-

Total area of longitudinal steel

- b :

-

Width of reinforced concrete section

- d bl :

-

Bar diameter of longitudinal reinforcement

- d bs :

-

Bar diameter of confinement reinforcement

- f c′:

-

Concrete compressive strength based on standard cylinder test

- f yl :

-

Yield strength of longitudinal reinforcement

- f yt :

-

Yield strength of transverse reinforcement

- h :

-

Height of reinforced concrete section

- L′:

-

Free length of Column

- P :

-

Axial force

- Po:

-

Nominal axial column strength at zero eccentricity (Eq. 22.4.2.2-ACI318-14)

- s :

-

center-to-center spacing of tie reinforcement along column height

- s 1 :

-

Center-to-center spacing of laterally supported longitudinal reinforcement

- V :

-

Shear force

- \(\mu_{\Delta }\) :

-

Displacement ductility factor

- ρ l :

-

Longitudinal reinforcement ratio determined as ratio of total area of longitudinal reinforcement to gross cross-sectional area

- ρ s :

-

Volumetric ratio of transverse reinforcement determined as total volume of transverse reinforcement divided by volume of concrete

- Δ1 :

-

Identical to yield displacement

- Δ2 :

-

Identical to ultimate displacement

References

ACI 318 (2014) Building code requirements for reinforced concrete (ACI 318-14) and commentary (ACI 318R-14). American Concrete Institute, Farmington Hills

ACI 363 (2010) Report on high strength concrete. American Concrete Institute, Farmington Hills

ACI-ASCE 441R (2010) High-strength concrete columns: State of the Art, American Concrete Institute, Manual of Concrete Practice (MCP) Part5, Farmington Hills

ACI-SP293 (2013) Reinforced concrete columns with high strength concrete and steel reinforcement, American Concrete Institute, Farmington Hills

Al-Hussaini A, Regan PE, Xue HY, Randame KE (1993) The behavior of HSC columns under axial load. In: International Symposium on utilization of high strength concrete, vol. 3

ASCE 41 (2013) seismic evaluation and retrofit of existing buildings, ASCE standard ASCE/SEI 41-13. American Society of Civil Engineers

Azizinamini A, Kuska SSB, Brungardt P, Hatfield E (1994) Seismic behavior of square high-strength concrete columns. Struct J 91(3):336–345

Bayrak O, Sheikh SA (1997) High-strength concrete columns under simulated earthquake loading. ACI Struct J 94:708–722

Bayrak O, Sheikh SA (2004) Seismic performance of high strength concrete columns confined with high strength steel. In: 13th World Conference on Earthquake Engineering, pp 1–6

Bjerkeli L, Tomaszewicz A, Jensen JJ (1990) Deformation properties and ductility of high-strength concrete. Spec Publ 121:215–238

Chung H, Hayashi S, Kokusho S (1980) Reinforced high strength concrete columns subjected to axial forces, bending moments, and shear forces. Trans Jpn Concr Inst 2:335–342

CSA A23.3 (2014) Design of concrete structures. Canadian Standards Association

Cusson D, Paultre P (1994) High-strength concrete columns confined by rectangular ties. J Struct Eng 120(3):783–804

Ding H, Liu Y, Han C, Guo Y (2017) Seismic performance of high-strength short concrete column with high-strength stirrups constraints. Trans Tianjin Univ 23(4):360–369

Ekasit L (1993) Strength of high-strength concrete columns. In: Proceedings of the symposium on high-strength concrete. Norway, Lillehammer

Elwood KJ, Maffei J, Riederer KA, Telleen K (2009a) Improving column confinement; Part 1: assessment of design provisions. Concr Int 31(11):32–39

Elwood KJ, Maffei J, Riederer KA, Telleen K (2009b) Improving column confinement; Part 2: proposed new provisions for the ACI 318 building code. Concr Int 31(12):41–48

FEMA 461 (2007) Interim testing protocols for determining the seismic performance characteristics of structural and nonstructural components. Federal Emergency Management Agency, Washington

Fib (2008) Constitutive modeling of high strength/high performance concrete, State of Art Report. Prepared by Task Group 8.2, Bulletin 42

Gaitan J (2017) Retrofit of Reinforced concrete columns. Doctoral dissertation, The Ohio State University

Ghosh SK, Saatcioglu M, Paultre P (1998) Confinement of high-strength concrete. ACI Spec Publ 176:105–136

Hammad YH (2010) Experimental performance of hsc columns under cyclic loads, Ph.D. Dissertation, Benha University, Egypt

Hatanaka S, Tanigawa Y (1992) Lateral pressure requirements for compressive concrete. In: Proceedings of 10th world conference on earthquake engineering, Madrid, pp 2603–2608

Hwang SK, Yun HD, Park WS, Han BC (2005) Seismic performance of high-strength concrete columns. J Mag Con Res 57(5):247–260

Hwang SJ, Hwang GJ, Chang FC, Chen YC, Lin KC (2013) Design of seismic confinement of reinforced concrete columns using high strength materials. ACI Spec Publ 293:21–34

Ishikawa Y, Kimura H, Takatsu H, Ousalem H (2008) Ultimate deformation of R/C columns using high-strength concrete and high-strength steel bars under earthquake loading. In: Proceedings

Jin L, Li D, Du X (2016) Mechanical behavior and size effect of moderate high-strength RC columns under monotonic and cyclic axial compression. Eng Struct 124:269–285

Kabeyasawa T, Li KN, Huang K (1990) Experimental study on strength and deformability of ultrahigh strength concrete columns. Trans Jpn Concr Inst 12:315–322

Kabeyasawa T, Shen FH, Kuramoto H, Rubiano NR (1991) Experimental study on behavior of ultra-high-strength reinforced concrete columns under tri-axial forces. Trans Jpn Concr Inst 13:279–286

Kato D, Watanabe F, Nishiyama M, Sato H (1998) Confined concrete with high-strength materials. ACI Spec Publ 176:85–104

Kimura H, Ishikawa Y, Takatsu H, Ousalem H (2013) Design issues and application of high strength concrete for high rise buildings. ACI Spec Publ 293:1–19

Mander JB, Priestley MJ, Park R (1988) Theoretical stress-strain model for confined concrete. J Struct Eng 114(8):1804–1826

Martinez S, Nilson AH, Slate FO (1982) Spirally reinforced high-strength concrete columns. Research Report No. 82-10, Department of Structural Engineering, Cornell University, Ithaca, N.Y

Martirossyan A, Xiao Y (2001) Flexural-shear behavior of high-strength concrete short columns. Earthq Spect 17(4):679–695

Muguruma H, Watanabe F, Komuro T (1990) Ductility improvement of high strength concrete columns with lateral confinement. ACI Spec Publ 121:47–60

Mugurumu H (1991) Ductile behaviours of high strength concrete columns confined by high strength transverse reinforcement. ACI Spec Publ 128:877–892

Murthy AR, Iyer NR, Prasad BKR (2013) Evaluation of mechanical properties for high strength and ultrahigh strength concretes. Adv Concr Const 1(4):341–358

Nagashima T, Sugano S, Kimura H, Ichikawa A (1992) Monotonic axial compression test on ultra-high-strength concrete tied columns. In: 10th world conference on earthquake engineering, vol. 5, pp 2983–2988

Nishiyama M, Fukushima I, Watanabe F, Muguruma H (1993) Axial loading tests on high-strength concrete prisms confined by ordinary and high-strength steel. In: Proceedings of symposium on high-strength concrete, pp 322–329

Ou YC, Kurniawan DP, Handika N (2013) Shear behavior of reinforced concrete columns with high-strength steel and concrete under low axial load. ACI Spec Publ 293:149–164

Park R (1989) Evaluation of ductility of structures and structural assemblages from laboratory testing. Bull N Z Natl Soc Earthq Eng 22(3):155–166

Park R, Tanaka H, Li B (1998) Flexural strength and ductility of high-strength concrete columns. Spec Publ 176:237–258

Ramezanianpour AA (2014) Cement replacement materials-properties, durability, sustainability. Springer, Heidelberg

Rangan BV, Saunders P, Seng EJ (1991) Design of high-strength concrete columns. ACI Spec Publ 128:851–862

Razvi SR, Saatcioglu M (1994) Strength and deformability of confined high-strength concrete column. ACI Struct J 91(6):678–687

Saatcioglu M (1991) Deformability of reinforced concrete columns. ACI SP 128:421–452

Saatcioglu M, Razvi SR (1992) Strength and ductility of confined concrete. J Struct Eng 118(6):1590–1607

Saatcioglu M, Razvi S (1993) Behaviour of confined high-strength concrete columns. In: Proceedings of CPCA/CSCE Structural Concrete Conference, Toronto, May

Sakai Y (1990) Experimental studies on flexural behavior of reinforced concrete columns using high-strength concrete. Jpn Concr Inst, Tokyo

Seong DJ, Kim TH, Oh MS, Shin HM (2011) Experimental performance of HSC columns under cyclic loads. J Adv Con Tech 9(2):205–220

Sezen H (2002) Seismic behavior and modeling of reinforced concrete building columns. Ph.D. Disseration, University of California, Berkeley

Sharma UK, Bhargava P (2005) Behavior of confined high strength concrete columns under axial compression. J Adv Concr Technol 3(2):267–281

Sheikh SA, Yeh CC (1990) Tied concrete columns under axial load and flexure. J Struct Eng 116(10) 2780–2800

Shiekh SA, Khoury SS (1993) Confined concrete column with stubs. ACI Struct J 90(4) 414–431

Sudo E, Masuda Y, Abe M, Yasuda M (1993) Mechanical properties of confined high-strength concrete. In: Proceedings of the symposium on high-strength concrete, pp 369–376

Sugano S, Nagashima T, Kimura H, Tamura A, Ichikawa A (1990) Experimental studies on seismic behavior of reinforced concrete members of high-strength concrete. Spec Publ 121:61–88

Thomsen JH, Wallace JW (1992) A study of high-strength reinforced concrete columns subjected to lateral and axial loads. Department of Civil Engineering, Clarkson University, Potsdam

Watanabe F, Muguruma H, Matsutani T, Sanda D (1987) Utilization of high strength concrete for reinforced concrete high rise buildings in seismic area. In: Utilization of high strength concrete proceeding, Stavanger, Norway, Tapir Publishers, 655-666

Woods JM, Kiousis PD, Ehsani MR, Saadatmanesh H, Fritz W (2007) Bending ductility of rectangular high strength concrete columns. Eng Struct 29(8):1783–1790

Yong YK, Nour MG, Nawy EG (1988) Behavior of laterally confined high-strength concrete under axial loads. J Struct Eng 114(2):332–351

Zhu W, Jia J, Gao J, Zhang F (2016) Experimental study on steel reinforced high-strength concrete columns under cyclic lateral force and constant axial load. Eng Struct 125:191–204

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Taheri, A., Moghadam, A.S. & Tasnimi, A.A. Critical factors in displacement ductility assessment of high-strength concrete columns. Int J Adv Struct Eng 9, 325–340 (2017). https://doi.org/10.1007/s40091-017-0169-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40091-017-0169-6