Abstract

The most important indicator of the radioactive waste classification and detection system is its identifiable minimum activity of low level radioactive waste, that is, the lower detection limit. In order to design a low level and very low level waste classification and detection system that can perform large-scale and rapid measurement, and explore the influence of various factors on the low limit of detection, this paper establishes the layout model of the detection unit of the classification detection system by Monte Carlo method to simulate the number of NaI crystals, the density of the detected object, the distance between the detection crystal and the detected object, the distance between the adjacent measured waste and the measurement time, etc. Meanwhile this paper analyzes the characteristics of the low limit of detection, and performs operations research analysis based on the principle of being able to detect radioactive waste with specific activity of not less than 0.1 Bq·g−1, maximizing the shielding effect and optimizing the shielding weight, and designs a low level and very low level waste classification and detection system that can measure radioactive waste which density is not less than 0.25 g/cm3 and which specific activity is not less than 0.1 Bq·g−1.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

During the decommissioning of nuclear facilities, a large amount of radioactive waste will be generated, covering different types of waste such as medium, low and very low level radioactive and clearance level waste. According to Chinese current radioactive waste classification standard, different types of radioactive waste need to adopt different disposal methods. Timely and accurate classification of decommissioned nuclear facilities is one of the key links in radioactive waste management, and it is also an important means to minimize waste and reduce disposal and supervision costs [1,2,3,4,5].

When using physical measurement techniques such as radiation detection to classify radioactive waste, especially when classifying clearance level waste (EW), very low-level waste (VLLW) and low-level waste (LLW), due to the very low level of radioactivity of the first two types of waste, the low limit of detection of instrument used has higher requirements. Therefore, this paper refers to other classification detection devices (e.g. box-type waste detecting device and waste barrel gamma scanning device) and uses Monte Carlo calculation software to simulate the low limit of detection of the module of a low-very low radioactive waste classification detection system, and studies relationship between the different detection crystal volume and crystal arrangement, different measurement time, different shielding thickness around the detection crystal, the distance between the detection crystal and the upper surface of the waste, and the density with the low limit of detection, and optimizes the detection module of the low-very low radioactive waste classification detection system.

2 Materials and Methods

2.1 Detector Source Response Coefficient

The detector source response coefficient K of the classification detection system is an important design parameter of the detector, that is, the counting rate generated by the radioactive source per unit specific activity in the measurement chamber of the classification detection system in the detector. In the development phase, we uses the F8 counting card in the MCNP program and SCORE card in the FLUKA program to simulate the calculation to obtain the pulse count rate produced in the detector in the measurement chamber of the specific activity of the waste in the detector. Detector source response coefficient.

where K is the detector source response coefficient of the classification detection system, cps·Bq−1·m−3; TallyF8 is counting rate (energy range of 100 keV ~ 3 meV), cps; V is the volume of waste to be measured in the simulation calculation, m3; I is the decay branch ratio of gamma rays produced by radionuclides in the waste to be measured.

2.2 Minimum Detectable Concentration

Minimum detectable concentration (MinDC, MDC) [4,5,6] represents the minimum activity concentration value that the classified detection system can analyze for specific nuclides in the measured waste. It is an important indicator of the sensitivity of the classification detection system when it is applied in a given situation. The premise that the waste to be tested can be reliably detected is that the activity concentration of the waste to be measured is greater than the minimum detectable concentration.

where: MinDC is the minimum detectable concentration, Bq·m−3; lb is the environmental background count rate, cps; t is the given measurement time, s.

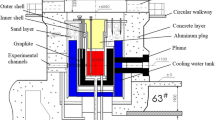

2.3 Model of Simulation

As shown in Fig. 2, this paper establishes the detection module model in the above-mentioned radioactive waste classification detection system in the Monte Carlo simulation software MCNP and FLUKA. In the calculation model, the size of a single NaI crystal is 40 cm × 10 cm × 5 cm; the size of the waste detection box ( stainless steel) is 65 cm × 65 cm × 10 cm; the radioactive source term is divided into two parts. One is the environmental background, and it is considered that the environmental dose rate in the working area of the detection system is the upper limit of the white area’s dose rate, and it is equivalent to a uniform spherical shell surrounding the whole detection device. The spherical shell is a source of air uniformly distributed with Cs-137 sources. The other part is the radioactive waste contained in the detection box, which is set as a cuboid source in the simulation.

3 Results and Discussion

3.1 Effect of Crystal Arrangement on the Low Limit of Detection

According to the Nuclear Safety Guidelines HAD401/04 “Radioactive Waste Classification”, the level of Cs-137 control is 0.1 Bq·g−1, that is, the classification detection system for requirements of Cs-137.

Usually, the larger the crystal volume or the number of crystals are, the smaller the low limit of detection is. However, due to the high volume NaI crystal price, this paper selects several different NaI detection crystal arrangement and quantity as shown in Fig. 1 to simulate the detection of the lower limit change, in order to choose the most cost-effective crystal arrangement and quantity. As shown in Fig. 3(a), when the background count rate is 5 cps·cm−3 and when the detection time is 30 s, no detection scheme can meet 0.1 Bq·g−1; when the detection time is 60 s, at least 4 NaI detection crystals should be selected to meet 0.1 Bq·g−1; as shown in Fig. 3(b), when the background count rate is 0.5 cps·cm−3, there is no limit to the number of NaI detection crystal blocks; in Fig. 3(a)(b), it shows that the detection efficiency of the 8 NaI crystal tiling type is better than the detection efficiency of the two-layer superposition form, mainly because the gamma ray energy is low, and the radiation energy can be deposited by selecting one layer of crystal, and the two-layer superposition form increases the lower limit of background influence detection caused by the crystal itself.

3.2 Effect of Average Distance Between Detector and Waste Upper Surface on Low Limit of Detection

In the actual measurement process of the radioactive waste classification detection system, the average distance between the detector and the waste surface is required to be adjustable, so as to avoid the overflow of the waste to be detected and the detector can achieve the best detection effect, so different source distances are used to simulate the change of the low limit of detection. As shown in Fig. 4, it can be seen that the low limit of detection increases as the average distance between the detector and the upper surface of the waste increases. Figure 4(a), when the NaI background count rate is 5 cpsˑcm−3 and when the measurement time is 60 s, the average distance between the NaI detector and the upper surface of the waste should not exceed 10 cm, even if the measurement time is relaxed to 120 s, the average distance should not exceed 20 cm. And when the NaI background count rate is 0.5 cpsˑcm−3, the average distance between the NaI detector and the upper surface of the waste should not exceed 50 cm.

3.3 Influence of the Density of Waste to be Measured on the Low Limit of Detection

In addition, the types of waste of the decommissioning of nuclear facilities are various and the density varies greatly, including metal materials such as steam generators in nuclear power plant, waste gas masks, and radioactive medical waste. In order to explore the impact of waste density on the low limit of detection and avoid discomfort to the detection system due to excessive or small waste density, different waste densities are used to simulate changes in the low limit of detection.

As shown in Fig. 5, under the same measurement conditions, the low limit of detection decreases with increasing waste density. Figure 5(a) when the measurement time is 60 s, if the NaI background count rate is 5 cps·cm−3, the waste density should not be less than 0.25g·cm−3. Figure 5(b) when NaI background count rate is 0.5 cps·cm−3 there are no restrictions on waste density.

3.4 Effect of Shielding on the Low Limit of Detection

The background count rate in the NaI detection crystal mainly comes from the noise of the NaI crystal, the environmental background of the area where the detection system is located, and the adjacent waste box to be tested. From the above analysis, it can be seen that the background count rate of different levels also has an important impact on the detection lower limit, so shielding must be set around the detector. Since the noise of the NaI crystal itself cannot be eliminated by shielding, and the background count rate in the NaI detection crystal with different intervals of the waste box to be detected is not shielded. The result is shown in Table 1. The environmental background is much lower than the influence of the adjacent waste box to be detected on the background of the NaI detection crystal, so the following only simulates the waste box to be detected at different intervals, changes in the lower limit of detection under different shielding thicknesses.

As shown in Fig. 6(a), when the spacing between adjacent waste boxes is 1 m, the thickness of the shielding lead layer is 2 cm and 4 cm, respectively, the background count rate can be reduced to 5 cpsˑcm−3 and 0.5 cpsˑcm−3 as shown in Fig. 6(a) and (b), when the spacing between adjacent waste boxes is 1.5 m or more, the background count rate can be reduced to 5 cpsˑcm−3 and 0.5 cpsˑcm−3 when the thickness of the shielding lead layer is 1 cm and 3 cm, respectively. As shown in Table 2, for a conservative estimate, when the distance between adjacent waste boxes is selected for 1 m, the background count rate is reduced to 5 cpsˑcm−3 and 0.5 cpsˑcm−3, respectively. The weight of lead shielding is about 139.3 kg and 303.1 kg, because the aging lead used for shielding is expensive, so it is proposed to use 2 cm thickness lead shielding.

4 Conclusions

In this paper, Monte Carlo software MCNP and FLUKA are used to simulate the influence of the number of NaI crystals, the composition of the measured object, the distance between the detection crystal and the measured object, and the measurement time on the lower limit of detection. The results show that:

-

1)

In the case of the same arrangement method, the lower limit of detection varies with the increase in the number of detected crystals; the low limit of detection of the tiling type is better than the two-layer superposition form; it is expected to use 8 NaI crystal tiling type arrangement method in engineering.

-

2)

The low limit of detection deteriorates as the average distance between the detector and the upper surface of the waste increases;

-

3)

The low limit of detection increases with increasing waste density;

Taking into account the weight and shielding effect of lead shielding, it is proposed to use 2 cm thickness lead shielding to reduce the background count rate to 5 cps·cm−3 below, at the same time, the average distance between the NaI detector and the upper surface of the waste should be controlled at 20 cm, and the waste density should be controlled not less than 0.25 g·cm−3.

Based on the above research contents, this paper designs the device as shown in the Fig. 7. The conveyor transports the detection cassettes containing the radioactive waste into the detection chamber with shielding and collimation through the pedrail. The source-less efficiency and energy spectrum analysis program completes the calibration and measurement of the waste, according to which the radioactive of the waste is judged and classified, and the transmission device is controlled to continue to move.

References

Ministry of Environmental Protection, Ministry of Industry and Information Technology, National Defense Science and Industry Bureau. Classification of Radioactive Waste (2017)

Ren, X., Liu, W.: Radwaste management for nuclear facility decommissioning. Radiat. Prot. Bull. 28(4), 1–7 (2008)

Wang, P., Liao, Y., Wei, G., et al.: The requirement of radioactive waste clearance level. Nucl. Saf. 14(2), 6–11 (2015)

Teng, Y., Zuo, R., Wang, J.: Technical methods of evaluation of nearsurface disposal of very low level radioactive waste. Bull. Mineral. Petrol. Geochem. 30(1), 59–64 (2011)

Xie, Y.: Summarization of safety assessment on disposal of low level radioactive wastes. Sichuan Environ. 30(5), 54–58 (2011)

Hao, R.: Practical formulae for the detection limit in low-level radioactivity measurement. Acta Metrologica Sinica 4(4), 303–310 (1983)

Sha, L., Wei, W., Xuan, Y.: Study on processing method of data near the lower limits of detection for radiation environmental monitoring. Admin. Technique Environ. Monit. 18(1), 38–43 (2006)

Huang, N.: Concept and calculation of detection limit in low level radioactive sample measurement. Radiat. Prot. Bull. 24(2), 25–32 (2004)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Chang, K. et al. (2023). Design of Radioactive Waste Classification and Detection System for Nuclear Facility Decommissioning. In: Liu, C. (eds) Proceedings of the 23rd Pacific Basin Nuclear Conference, Volume 1. PBNC 2022. Springer Proceedings in Physics, vol 283. Springer, Singapore. https://doi.org/10.1007/978-981-99-1023-6_91

Download citation

DOI: https://doi.org/10.1007/978-981-99-1023-6_91

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-1022-9

Online ISBN: 978-981-99-1023-6

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)