Abstract

The lack of fast neutron irradiation test equipment is a key practical factor that restricts the development of the new generation nuclear energy technology with fast reactor as the core in China. Scarce isotopes such as californium 242, which are urgently needed in industry and medicine, are also highly dependent on imports. In order to provide a fast reactor material irradiation environment and isotope production environment, significantly accelerate the development of fast reactor fuel and structural material technology, and improve the efficiency of rare isotope production, this paper proposes a multifunctional inherently safe ultra-high flux reactor design with fast/thermal neutron flux levels up to 1016 n/(cm2.s), namely UFR-1016. The neutron energy spectrum covers fast spectrum, superheat spectrum and thermal spectrum; several material irradiation test orifices, isotope production orifices and test loop orifices are arranged in the core, and the test loop supports many new reactor coolants such as H2O, Na, He, He-Xr, molten salt, etc., and supports the simulation of typical transient processes and accident conditions. This paper discusses the overall construction scheme of the reactor, and the current construction scheme shows that each performance index can meet the target requirements and achieve the expected functions while ensuring the safety performance of the reactor. This study can provide a basis for the development of ultra-high flux reactors and provide strong support for the cause of nuclear energy, nuclear technology, and nuclear medicine in China.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The research and development of cleaner, more efficient, and safer new nuclear energy systems is of great significance to the sustainable development of nuclear energy, and the performance of nuclear fuel and structural materials, especially their irradiation performance, has always been an important basis for the development of new nuclear energy systems. The irradiation experiment of materials is mainly carried out in the research reactor. The irradiation test ability of the research reactor is mainly determined by the neutron flux level. The higher the neutron flux level, the faster the irradiation test of materials and shorten the research and development cycle of materials.

The construction of high-flux reactors is of great benefit to the entire nuclear energy field. In the 1960s, thermal spectrum and fast spectrum research reactors were built and put into use in various countries around the world. In terms of thermal spectrum research reactors, Russia and Belgium have built high-flux research reactors SM-2 [1] and BR-2 [2] respectively, and the United States has built HFIR [3] and ATR [4]. Among them, the HFIR thermal neutron flux is about 2.5 × 1015 cm−2s−1, which is one of the research reactors with the highest steady-state thermal neutron flux. Most of the 252 Cf in the world comes from here; the ATR thermal neutron flux is about 1 × 1015 cm−2s−1, with a power level of 250 MW, is one of the research reactors with the highest power level and has a strong material irradiation capability. In terms of fast-spectrum research reactors, Russia's BOR-60 [4] has not yet been retired, and the United States’ EBR-II [6] and FFTF [7] were retired in the 1990s for political and economic reasons, but also has left quite a wealth of experience and relatively mature technology to American fast-spectrum reactors (especially sodium-cooled fast reactors). The development of high flux research reactors in China is relatively late compared to other countries. The thermal spectrum research reactor HFETR [8] was critical in 1979, and the fast spectrum research reactor CEFR [9] was critical in 2010.

In 2002, the International Forum on Generation IV Nuclear Energy Systems proposed six priority development of Generation IV nuclear energy systems, most of which are fast reactors. The development of fast reactors is inseparable from the corresponding material irradiation experiments. However, the existing thermal spectroscopy research reactors have limited irradiation capabilities, and it is difficult to match the development and research speed of fast reactors. France started construction of the water-cooled research reactor JHR [10] in 2007, Russia started the construction of the sodium-cooled research reactor MBIR [11] in 2015, and the U.S. sodium-cooled fast reactor VTR [12] has also been put on the agenda. It can be seen that the overall development trend of foreign research reactors is to develop towards high-flux fast reactors. At the same time, more advanced irradiation methods are required, such as independent coolant circuits, on-line monitoring equipment in the reactor, and particle beam pipelines, etc.

Among the fourth-generation advanced nuclear power systems, fast reactor is one of the most promising reactor types. At present, there is an extreme lack of data on fast neutron irradiation of reactor materials in China, and there is also a lack of fast neutron irradiation research reactor. In addition, scarce isotopes such as californium 242, which are urgently needed in industry and medicine, are also highly dependent on imports. In order to provide fast reactor material irradiation environment and isotope production environment, greatly accelerate the research and development of fast reactor fuel and structural materials technology, and improve the production efficiency of scarce isotopes, this paper proposes a multifunctional intrinsically safe ultra-high flux reactor design with fast/thermal neutron flux level up to 1016 n/(cm2.s), namely UFR-1016, and discusses the overall construction scheme.

2 The Design Goals of the Ultra-high Flux Reactor

According to the current demand for research reactors, the overall design goal of UFR is to cover the fast spectrum, super thermal spectrum and thermal spectrum with fast/thermal neutron flux up to 1016 n/(cm2.s); A number of material irradiation test channels, isotope production channels and test circuit channels are arranged in the core. The test circuit supports many new reactor coolants such as H2O, Na, he, He-Xr, molten salt, etc., supports the simulation of typical transient processes and accident conditions, and meets the strong needs of radiation test and performance test of nuclear fuel and materials, transient and typical accident simulation. The ultra-high-flux multi-function reactor is facing the frontier of world science and technology, and aims to surpass the comprehensive research facilities such as the VTR under construction in the United States and the MBIR under construction in Russia. The key parameters are shown in Table 1.

3 Ultra-high Flux Reactor Construction Scheme

The overall construction plan of the research reactor includes: a key system, namely, ultra-high flux inherently safe nuclear reactor system; Three large-scale test loop systems, namely, advanced nuclear fuel and material steady-state test loop (coolant could be Na, Pb, Pb Bi, CO2, He, H2O, etc.), reactor transient behavior simulation test loop (through radial movement, realize rapid and controllable adjustment of fuel power, and carry out research on transient characteristics of fuel elements under the conditions of power jump, load follow, reactivity introduction, etc.) and accident simulation test circuit (meet the functional requirements of operating condition simulation, triggering of the accident condition, accident mitigation, fuel failure and fission product monitoring); A neutron science experiment platform, which can provide horizontal channels of neutron beams with different energies; Carry out experimental research on irradiation and neutron activation of small-size materials. Figure 1 shows the general layout of ultra-high flux reactor. The construction schemes of these systems will be discussed below.

3.1 Inherent Safety Nuclear Reactor System Scheme of Ultra-high Flux Reactor

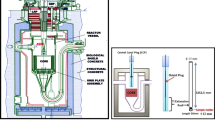

Table 2 shows the overall design parameters and design choices of the intrinsically safe nuclear reactor system of ultra-high flux reactor. The rated thermal power of the reactor is set at 200 MW, and the refueling cycle is 90 days. Lead-bismuth eutectic (LBE) is selected as the core coolant, which has good neutron physical properties, thermophysical properties and chemical properties. The reactor core is arranged as an atmospheric pool with a height of 450 mm, a temperature of 165/350 ℃ at the inlet and outlet of the core, and a maximum coolant flow rate of 4.0 m/s. As for the selection of the fuel, considering the characteristics of the core, such as high fast neutron flux, hard neutron energy spectrum and high power density, the U-Zr metal fuel with high U density, few moderating elements and good heat conduction is selected, zirconium alloy with excellent neutron property, mechanical property and irradiation property is a good choice as cladding material.

The natural circulation of coolant in the circuit is sufficient to cool the reactor without the risk of residual heat export from the reactor core, and the reactor protection vessel is arranged in the passive heat conduction system tank filled with water. The primary circuit system mainly includes: reactor core, steam generator module, main pump, and internal radiation shielding, which is located in the reactor vessel. The secondary circuit system mainly includes: steam generator module, feedwater and steam pipelines, steam-water separator, and independent cooler. The LBE coolant is heated by the core, enters the core outlet chamber and flows out laterally, enters the steam generator from the bottom of the primary circuit, and is cooled by the secondary loop at the same time. When the coolant reaches the top of the primary side of the steam generator, it turns over and enters the main pump, and then the coolant is transported by the main pump from top to bottom to the reactor inlet chamber. The protective gas system mainly includes: gas system condenser, membrane safety device, pressure relief device and pipeline. The coolant process system mainly includes: LBE filling and discharging system, purification system and real-time online monitoring system, which are used to maintain the quality of LBE in the system during operation. The safety system mainly includes reactive accident protection system, steam generator leakage suppression system, independent cooling system and passive residual heat removal system. In addition, the refueling system needs to be set up.

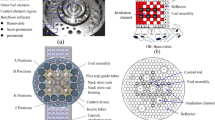

Among them, the reactor core is the key part. The layout of the reactor core is shown in Fig. 2. The high-power density standard fuel assembly is located in the central area, and the periphery is the shielding assembly. In order to improve the reactivity control ability and reliability, two kinds of control rod systems with different principles are set up. The holes for the irradiation test of advanced nuclear fuel and materials are located in the central zone of the core with ultra-high neutron flux. The holes for the nuclear reactor transient test and the typical accident simulation test are located in the reflector area of the core. And several material irradiation test holes are set in the high-power density fuel area and emitter area of the core. Several horizontal and vertical experimental channels are set in the radial direction of the reactor (mainly used for neutron scattering experiments, neutron photography and other basic research of Neutron Science).

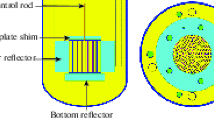

In order to improve the power density of the reactor core and reduce the problem of fuel core, considering the swelling of fuel elements caused by axial and radial temperature differences, irradiation and other factors, and referring to the design ideas of fuel elements of European JHR, China's HFETR and other test reactors, the standard fuel assemblies in the high-power density area of the reactor core initially adopt the narrow rectangular fuel elements shown in Fig. 3. The core adopts high-performance U-10Zr metal fuel with an U235, enrichment of 64.4%., and the cladding material adopts T91.

In terms of thermal design criteria, due to the high boiling point of LBE, it is very difficult to boil, and the design criteria related to boiling threshold do not need to be considered. It is only necessary to consider operating temperature limits of the core and integrity requirements design limits of the cladding.

For narrow rectangular fuel elements, there is usually no gap to contain fission gas. In order to avoid the fission gas causing the fuel rod to swell and burst, the temperature of the fuel is usually limited to a certain range.

For U-Zr alloy fuel, the fuel temperature should be lower than 560 ℃. In order to maintain the integrity of the cladding, the coolant flow rate outside the fuel cladding and the maximum temperature on the outer surface of the cladding shall be limited. Among them, considering the heat carrying capacity of lead bismuth per unit volume, the coolant flow rate limit is relaxed to 4 m/s. The maximum temperature of the outer surface of the cladding is still limited to below 550 ℃. In the design process, the flow heat transfer model of the coolant channel refers to the previous research results [13,14,15].

Based on the overall design objectives and criteria, after repeated demonstration, the core design parameters are shown in Table 3, and the results show that it meets the core neutron flux requirements.

3.2 Advanced Nuclear Fuel and Material Irradiation Test Loop System

In order to speed up the research on the radiation mechanism of advanced nuclear fuels and materials, three forms of nuclear fuel and material irradiation tests can be carried out on ultra-high flux reactors, including static container irradiation test, instrumented irradiation test and loop irradiation test. Among them, the loop irradiation test can accommodate nuclear materials or fuels with large heat release and scaled fuel components and cladding materials requiring irradiation under actual operating conditions. The most significant advantage is that it can simulate the actual thermal hydraulic environment and hydro chemical environment, and accurately monitor and control irradiation parameters. This is one of the most complex and important test devices. The loop device is located in the center of the nuclear reactor and has ultra-high fast neutron flux. According to the different test tasks, the coolant can choose Na, Pb, Pb Bi, CO2, he, etc., and the inlet and outlet temperature can be adjusted according to the coolant type to meet the requirements of rapid screening and performance testing of advanced nuclear energy materials and nuclear fuel samples.

The loop device has an independent coolant circuit, which can independently control the coolant parameters in the device, such as pressure, temperature, flow rate, chemical composition, etc., and take away the heat generated by the test piece. By connecting with the computer control system, the emergency control and alarm functions are realized, and a variety of irradiation parameters are monitored online, including flow, temperature, pressure, differential pressure, fission products and water chemistry. The loop irradiation device needs to occupy multiple core cells, and the empty cell space outside the irradiation device is filled with special-shaped components (Fig. 4).

3.3 Nuclear Reactor Transient Behavior Simulation Test Loop System

In order to study the structural integrity and material irradiation behavior of fuel elements in advanced nuclear power system under transient conditions, the transient behavior simulation test of nuclear fuel with fast power up and down can be carried out on ultra-high flux reactor. The loop device is located in the reactor core reflector area and is mainly used for the power jump experiment in the irradiation environment to realize various hypothetical irradiation operating conditions for new fuel elements or irradiated fuel elements, such as power increase experiment, fuel rod internal pressure overpressure experiment, fuel rod free gas elimination experiment, fuel core melting experiment, etc. Rapid changes in neutron flux are achieved using device translation and/or He-3 loops, which in turn rapidly regulate the heat release rate of the test fuel element and its axial distribution. The loop device also has a separate coolant loop so that the coolant parameters in the device, such as pressure, temperature and flow rate, chemical composition, etc., can be controlled individually and take away the heat generated by the test piece. The connection to the computer control system enables emergency control and alarm functions, and online monitoring of a variety of irradiation parameters, including flow rate, temperature, pressure, differential pressure, fission products and water chemistry. The coolant circuit also features fission gas collection and is capable of on-line analysis of gas composition, taking into account the leakage of radioactive material after the breakage of the fuel cladding in transient tests. A fully automatic quick-disassembly joint is located above the unit to enable remote disassembly and assembly of fuel elements and to avoid high dose irradiation to the operator.

3.4 Accident Simulation Test Loop System

This loop device is located in the core reflector region and is mainly used for LOCA experimental simulations of LWRs to test the thermal-mechanical behavior of fuel elements and their cladding, and the radioactive consequences in case of breakage in the event of a LOCA accident at LWRs nuclear power plants.

The loop device is divided into two parts: the internal system and the external system (compartment). The internal reactor system is partially installed in the channel of the reflective layer (210 mm in diameter), and the internal reactor system is moved by the moving device (which can be moved radially by about 0.5 m). Its nuclear power is controlled by the distance between the fuel rod of the reactor system and the ultra-high flux multifunctional reactor vessel (close to the reactor system, the power is high, far away from the reactor vessel, the power is low) and by increasing or reducing the blocks between them. At the same time, the minimum distance between the mobile device and the reactor vessel and the blocks are limited to limit the maximum nuclear power. In addition, the anti-fly-out system is installed on the top of the reactor system and fixed on the mobile system to prevent the axial movement of the reactor system.

The reactor system is located in a double-layered bottle body made of stainless steel. The inner layer bottle is a pressure bottle body, which is used to bear the internal pressure. An air gap is formed between the inner and outer bottle bodies, which is filled with helium gas for thermal insulation. The flow separation tube is located in the inner bottle, forming two concentric channels, the hot channel surrounding the fuel sample, and the cold channel between the separation tube and the inner bottle. Thus, thermosiphon can be established to ensure fuel rod cooling before LOCA transient starts. The flow separation tube is integrated with the surrounding heater to form an adiabatic condition for the fuel in the adiabatic stage. The gap between the support structure of the in-reactor system and the outer bottle body forms a cooling channel, and the pump is used to provide forced circulation. The neutron shield (hafnium) is fixed on the inner side of the support structure of the in-reactor system to flatten the axial neutron flux. The test instruments are used to measure temperature and pressure.

The external reactor system (compartment) is connected to the internal system by cables. The main function of the external system is to ensure the initial structure of the internal system loop to control the emptying and re-flooding phases. The in-reactor system is connected to the fission product laboratory, where the contaminated fluid will be contained, analyzed and partially sampled during the final phase of the test. The sampling line at the bottom will be for water, while the top is for gas. The external reactor system (compartment) are also used to store contaminated gases and liquids (from the fission product laboratory), and the fluids will be stored in different containers depending on the level of contamination.

3.5 Neutron Science Experiment Platform

The device is located in the external area of the reactor, which is mainly used for neutron photography of highly reflective nuclear fuel elements, materials and large-scale equipment, analyzing its internal organization structure, and providing basic data for material performance evaluation and modification. The reactor horizontal channel provides neutron sources to the device.

The cooling pool outside the reactor provides a measurement environment that is closer to the operating parameters for the study of the behavior of nuclear materials in the reactor. Under this condition, the camera platform for highly radioactive materials has its unique advantages. Due to the difference in the interaction characteristics of neutrons and photons with matter, neutrons are sensitive to light materials, fissile materials and strong absorbing materials, while photons are sensitive to heavy materials; the attenuation of neutrons in matter is much smaller than that of photons, which is beneficial to Photography of heavy samples. Therefore, the neutron photography platform and the photon photography platform complement each other and have good complementarity in material detection.

The platform is located in the reactor pool and is used for neutron photography of new fuel and irradiated nuclear fuel with strong radioactivity. In order to achieve the neutron detection of large samples, indirect neutron imaging based on wedge-shaped neutron beam is adopted, and water provides effective neutron shielding for the photography platform. The underwater neutron and photon photography platform can meet the load-bearing requirements of most samples, which can not only realize rapid imaging of short-lived nuclides in irradiated samples, but also grasp the distribution of nuclides in the samples (such as distribution of special nuclides in fuel rods). Under the three-degree-of-freedom spatial motion adjustment of the sample holding mechanism, γ-ray passive tomography imaging of samples of any shape can be realized. In order to achieve different scanning effects, various shapes and types of gamma-ray front-end collimators are preset. Since the collimator penetrates the reactor pool wall, it is necessary to set up a shielding structure at the corresponding position outside the pool wall to achieve effective protection for devices and staff.

4 Conclusion

This paper proposes an ultra-high flux research reactor and discusses the reactor construction scheme, including the nuclear reactor system scheme and the design of each test loop. After demonstration and design, on the premise of ensuring the safety performance of the reactor, each performance index can meet the target requirements and achieve the expected functions:

-

1)

It can build a high-intensity, fast neutron spectrum and high-energy neutron field irradiation testing environment for the research and development of nuclear fuels and materials for the next generation and future advanced nuclear power systems, fusion reactors and other new reactors;

-

2)

It can significantly shorten the irradiation test time of nuclear fuel and nuclear materials, and improve the research and development efficiency of new nuclear fuel and nuclear materials; It can realize the deep depletion of nuclear fuel, and effectively meet the basic theoretical data required by researches such as closed fuel cycle and nuclear fuel transmutation theory;

-

3)

It can significantly improve the industrial production capacity and efficiency of 238 Pu, 252 Cf and other high value-added or scarce isotopes;

-

4)

It can provide a more powerful, stable, continuous horizontal neutron beam that can be used for neutron scientific research;

-

5)

It can provide the super-strong neutron field required by the fuel element to realize the step change of power for simulation experiments such as transient behavior and typical accidents of nuclear power plants.

References

Tsykanov, V.A., Korotkov, R.I., Kormushk, Y.P.: Some Physical Features of SM-2 Reactor, and Comparison of SM-2 with Other High-Flux Reactors. Meeting Abstract (1971)

Ponsard, B.: The BR2 high-flux reactor. ATW 57(10):, 612–613 and 583 (2012)

Cheverton, R.D., Sims, T.M.: Hfir Core Nuclear Design (1971)

O'Kelly, D.S.: The Advanced Test Reactor. Reference Module in Earth Systems and Environmental Sciences (2020)

Izhutov, A.L., Krasheninnikov, Y.M., Zhemkov, I.Y., et al.: Prolongation of the BOR-60 reactor operation. Nucl. Eng. Technol. 47(3), 253–259 (2015)

Koch, L.J.: Experimental Breeder Reactor-II (EBR-II) (1967)

Tobin, J.C.: FFTF and the ASME Code (1978)

Hong, Y., Bu, Y., Lin, J. : 10 Years Safety Operation of the High Flux Engineering Test Reactor(HFETR). Nuclear Power Engineering (1990)

Gu, C.X., Liu, et al.: Progress in China Experimental Fast Reactor. Annual Report of China Institute of Atomic Energy 00, 46–49 (2014)

Gilles, B., Christian, C., Jocelyn, P., et al. : The Jules Horowitz Reactor Research Project: A New High Performance Material Testing Reactor Working as an International User Facility – First Developments to Address R&D on Material. EPJ Web of Conferences 115, 01003-(2016)

Tuzov, A.: MBIR International Research Center: Current Progress and Prospects (2015)

Pasamehmetoglu, K.: Versatile Test Reactor Overview. Advanced Reactors Summit VI (2019)

Jaeger, W.H.W.L. : Liquid metal thermal hydraulics in rectangular ducts: Review, proposal and validation of empirical models: International Conference on Nuclear Engineering, Japan, JSME (2015)

Ushakov, P.A., Zhukov, A.V., Matyukhin, N.M. : Heat transfer to liquid metals in regular arrays of fuel elements. High Temp. (USSR)(Engl. Transl.); (United States) 15(5) (1978)

Mikityuk, K. : Heat transfer to liquid metal: Review of data and correlations for tube bundles. 239(4), 680–687 (2009)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Zhang, X., Yu, H., Xia, B., Li, W., Zhang, X. (2023). Research on Ultra High Flux Research Reactor. In: Liu, C. (eds) Proceedings of the 23rd Pacific Basin Nuclear Conference, Volume 1. PBNC 2022. Springer Proceedings in Physics, vol 283. Springer, Singapore. https://doi.org/10.1007/978-981-99-1023-6_75

Download citation

DOI: https://doi.org/10.1007/978-981-99-1023-6_75

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-1022-9

Online ISBN: 978-981-99-1023-6

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)