Abstract

Intrusion/erosion will cause mass loss of bentonite, resulting in endangering the operation safety of the repository for disposal of high-level radioactive waste. In this work, intrusion/erosion tests were conducted on GMZ bentonite specimens with a fracture aperture of 0.1, 0.5, 0.75 and 1.0 mm, as well as a duration of 60 days. Images were regularly captured with a digital camera. The intrusion distance and width of accessory-mineral ring were obtained. The erosion rate was determined by a turbidimeter. Meanwhile, parallel tests with a fracture aperture of 0.5 and 1.0 mm were repeated with a duration of 5, 15 and 30 days. After tests stopped, dry weight of specimens was measured. Results show that the intrusion distance increased with increasing fracture apertures, resulting in the increase of accessory-mineral-ring width, which will in turn restrict intrusion and erosion. Actually, the erosion rate in the early period decreased obviously with increasing accessory-mineral-ring widths, due to its filtration effects. However, when erosion reached stabilization, the erosion rate increased with increasing fracture apertures and intrusion distances but not independent of the accessory-mineral ring. The majority part of specimen mass loss ratio in the early period was from intrusion. But when intrusion reached stabilization, the mass loss ratio of specimen will be mainly contributed by erosion and would keep on increasing. Moreover, the mass loss ratios of specimens after 60 days by intrusion and erosion both increased with increasing fracture apertures. Meanwhile, the difference between the mass loss ratio by intrusion and erosion increased with increasing fracture apertures.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Deep geological disposal is considered as an effective way to solve the problem of safe disposal of high-level radioactive waste (HLW). According to the concept of this method, high-level radioactive waste is designed to store in a natural geological body (500–1000 m below the ground surface), in order to isolate it from the ecological environment for a long time or permanently. In this regard, compacted bentonite has been considered as a candidate buffer material for sealing the gaps and fractures in the repository [1,2,3,4]. Researches reveal that numerous fractures with various sizes would be inevitably encountered in the surrounding rock including those naturally originated or generated during construction activities, etc. [1, 13, 16]. Theses fractures could serve as channels for groundwater flow. Once compacted bentonite in the core area contacted with groundwater in the fractures, it will expand and squeeze into the fractures. Meanwhile, when the cation concentration in the groundwater is below the critical coagulation concentration (CCC) [8, 15], bentonite colloidal particles could be generated at the clay/water interface and carried away, resulting in bentonite erosion by flowing groundwater. The phenomenon that bentonite buffer material hydrated into fractures in the surrounding rock and then eroded away by groundwater was defined as bentonite intrusion/erosion. This intrusion/erosion behavior may cause significant mass loss of bentonite during the long-term operation of the repository, especially for the fractures with larger sizes. Therefore, it is of great importance to figure out the intrusion/erosion behavior of bentonite with consideration fracture aperture effects.

During past decades, numerous work has been conducted on the intrusion/erosion process of montmorillonite in artificial fractures. A two-dimension fracture formed by two transparent plates is designed and the intrusion/erosion tests were performed to investigate effects of the types of montmorillonite, water velocity and slope angle of the fracture on the intrusion distance and erosion rate. Vilks et al. (2010) found that the intrusion distance and erosion rate of Na-rich montmorillonite was significantly higher than Ca-rich montmorillonite [14]. Schatz et al. (2013) found that there was not enough test data to prove the relationship between the intrusion distance and flow velocity [12]. While the erosion rate of Na-rich montmorillonite increased with the increase of the flow velocity under the most dilute conditions (ionic strength < 1 mM). Subsequently, with the same apparatus, the influence of fracture angles on the intrusion distance and erosion rate was investigated by Schatz et al. (2016) [11]. It was observed that the intrusion distance was larger in the bottom half than that in the upper one, with the fracture angle of 45° and 90°. Moreover, an increase in erosion rate of Na-rich montmorillonite was observed with an increasing fracture slope angle from 0° to 90°.

In comparison with montmorillonite materials, the intrusion/erosion process of bentonite also has attracted much attention. The intrusion/erosion behavior of MX-80 bentonite with a naturally varying fracture aperture was investigated by Reid et al. (2015) [10]. It was found that an accessory-mineral ring, mainly composed of accessory minerals (such as quartz, felspar, etc.) was generated at the intrusion edge during the process of erosion. A two-stage cyclic intrusion/erosion mechanism was derived, that confirms the mitigating effects of accessory-mineral ring on the intrusion and erosion.

Previous studies have focused on the intrusion/erosion behavior with one single fracture aperture. However, the variability of the fracture aperture may play an important role in the development of the accessory-mineral ring, which may in turn inhibit intrusion and erosion [10]. Moreover, research of influence of intrusion/erosion on mass loss of bentonite has rarely been reported, which is necessary for assessing the deterioration process of buffer materials with fractures.

In this study, tests on intrusion/erosion of GMZ bentonite into artificial fractures were carried out with a fracture aperture of 0.1, 0.5, 0.75 and 1.0 mm, as well as a duration of 60 days, in order to evaluate the influence of fracture apertures on bentonite intrusion and erosion. Meanwhile, parallel tests with a fracture aperture of 0.5 and 1.0 mm were repeated with a duration of 5, 15 and 30 days. After tests stopped, the mass loss of specimens for each test could be determined. Based on these results, influences of the intrusion/erosion behavior and on the mass loss of bentonite were analyzed.

2 Methodlogy and Test Procedures

2.1 Apparatus

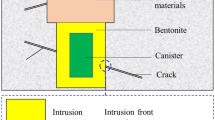

In this study, an experimental apparatus was developed (Fig. 1) for conducting intrusion/erosion tests. By inserting stainless-steel gasket into two transparent acrylic plates, a flow-through cell was generated between the two plates. Then, fractures with different sizes could be formed by adjusting the thickness of the gasket. Meanwhile, a hole for placing the specimen was set in the center of the apparatus. A cross-type counterforce frame was mounted on the upside of the acrylic plate (Fig. 1), to restrict the vertical deformation of the acrylic plate due to the specimen swelling. Finally, with a high-precision camera fixed above the test apparatus, the bentonite intrusion process could be monitored by taking images automatically at given time intervals.

2.2 Materials and Specimen Preparation

-

1)

Materials

Gaomiaozi (GMZ) bentonite was tested in this study, which was extracted from Inner Mongolia autonomous region of northern China [5, 6]. Its basic properties are listed in Table 1.

-

2)

Specimen preparation

For specimen preparation, 77.5 g of GMZ bentonite powder with an initial water content of 10.0% and filtrate conductivity below 10 µs/cm was statically compacted into a cylindrical specimen with a target height of 20 ± 0.5 mm, a diameter of 50.4 mm and a dry density of 1.70 ± 0.05 Mg/m3.

2.3 Test Procedures

In order to investigate the influence of fracture apertures on intrusion/erosion behavior, as well as the intrusion/erosion process on the mass loss of buffer materials, a total of 10 tests were conducted (Table 2).

First of all, after installation of the compacted bentonite specimen into the central compartment, a peristaltic pump was used to provide deionized water injected into the three inlets. A constant velocity of 8.3 × 10–5 m/s could be produced. Then, the camera was activated and images were regularly obtained. According to the relationship between the circular area and the radius, the intrusion distance (l) or width of the accessory-mineral ring (l1) could be derived,

where, \(S_1\) and \(S_2\) are the circular area of non-accessory and accessory-mineral ring, \(\theta\) is the angle of fan-shape area and r is the radius of specimen. (Fig. 2).

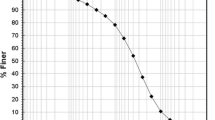

Meanwhile, with a portable turbidimeter (TN-100 from Eutech Instruments), the turbidity of outlet effluent was measured every 24 h. Then, according to the calibration curve shown in Fig. 3, erosion rate could be determined [2]. After the test, the specimen was pushed out and its dry mass was weighed.

New specimens were installed and procedures above were repeated. Until all the 10 specimens with respect to the various fracture apertures and test termination time were tested corresponding to their own specifications (Table 2), all the tests were completed.

3 Results

3.1 Intrusion Behavior

The intrusion stage with a fracture aperture of 1.0 mm during 60 days is presented in Fig. 4. As shown in Fig. 4, a ring of layered material (accessory-mineral ring) was formed and developed at the clay-water interface. This observation is consistent with the research by Reid et al. (2015) [10].

According to the ImageJ software, evolutions of intrusion parameters (intrusion distance and width of accessory-mineral ring) are obtained in Figs. 5 (a) and (b). It clearly shows that the intrusion distance and width of accessory-mineral ring both increased significantly in the early stage. Then, the two intrusion parameters increased more gradually and reached stability after 60 days. Moreover, for one given day, the two intrusion parameters increased with increasing fracture apertures.

3.2 Erosion Behavior

The erosion curve in terms of erosion rate versus time is shown in Figs. 6 (a). Results in Fig. 6 (a) show that the erosion rates with a fracture aperture of 1.0, 0.75, 0.5 and 0.1 mm decreased rapidly before 5 days. Then the erosion rates increased and reached a second peak value after 10, 9, 8 and 9 days, with a fracture aperture of 1.0, 0.75, 0.5 and 0.1 mm, respectively. Finally, their corresponding erosion rates decreased and kept stable around after 60 days.

Meanwhile, the evolutions of the accumulated erosion mass with time are depicted in Fig. 6 (b). It can be observed that the accumulated erosion mass increased significantly in the early period. Then, an obvious turning point of the erosion curve was observed. Moreover, for one given day, the accumulated erosion mass increased obviously with increasing fracture apertures.

3.3 Mass Loss Ratio of Specimens

With tests stopped, the specimens were pushed and weighed to obtain the dry mass. Then, for tests with a fracture aperture of 0.5 and 1.0 mm, the evolutions of mass loss ratio of specimens with time are obtained in Fig. 7. It appears in Fig. 7 that once the intrusion/erosion occurred, the mass loss ratios of specimens both increased rapidly and then followed by an obvious reduction in the increase rate after about 15 days.

Subsequently, the mass loss ratio of specimens after 60 days is plotted versus the fracture aperture in Fig. 8. It can be observed in Fig. 8 that the mass loss ratio of specimens increased significantly with increasing fracture apertures.

4 Discussion

4.1 Influences of Fracture Apertures on Bentonite Intrusion

According to the intrusion model by Svobody (2013) [13], the sidewall friction factor decreases with increasing fracture apertures. Therefore, the intrusion distance in the steady state is proportional to the fracture aperture. Meanwhile, based on this theory and the test result with fracture aperture of 0.1 mm, the predicted intrusion distance after 60 days versus fracture apertures could be obtained in Fig. 9. However, it appears in Fig. 9 that the predicted value was obviously larger than the measured one, especially for tests with a larger fracture aperture. This observation could be due to the mitigating influence of the accessory-mineral ring on intrusion (Reid et al., 2015) [10] and its explanation could be given as follows. According to the research by Moreno et al. (2011) [7], the erosion rate would increase with increasing intrusion distances, leading to more accessory minerals left at the clay/water interface. Accordingly, the width of accessory-mineral ring would increase correspondingly with increasing intrusion distances and more significantly with a larger fracture aperture. Indeed, according to Figs. 5 (a) and (b), the relationship between the width of accessory-mineral ring and intrusion distance could be obtained in Fig. 10. The width of accessory-mineral ring increased with increasing intrusion distances and was larger with increasing fracture apertures, which confirmed the conclusion above. Therefore, as the fracture aperture and intrusion distance increase, the larger width of accessory-mineral ring may lead to the more restrictive effects on intrusion. In this regard, the intrusion model proposed by Svobody (2013) [13] could not be used for simulating the intrusion behavior in this study, especially with a larger fracture aperture.

4.2 Influences of Fracture Apertures on Bentonite Erosion

According to research by Neretnieks et al. (2017) [9], the erosion rate (Nerosion) could be calculated as,

where, \(\rho_s\) is the density of montmorillonite, \(\delta\) is the fracture aperture, \(\phi_c\) is the volume fraction of montmorillonite at the intrusion front, D is the diffusion coefficient, u is the flow velocity, l is the intrusion distance and r is the radius of specimens.

For one given fracture aperture, based on this erosion model (Eq. (3)), the erosion rate will increase with the increase of the diffusion coefficient and intrusion distance. However, according to Figs. 5 (a) and Fig. 6 (a), it is clear that the erosion rate in the early stage decreased significantly with the increase of the intrusion distance and accessory-mineral-ring width, indicating that the development of the accessory-mineral ring would lead to the reduction in the diffusion coefficient [10]. After the intrusion distance reached stabilization, the erosion rate basically remained unchanged. According to Eq. (3), it can be concluded that the diffusion coefficient would also keep constant in the steady state. Meanwhile, according to Figs. 5 (a) and Fig. 6 (b), the relationship between the final average erosion rates after 60 days and \(\delta \sqrt {\left( {l + r} \right)}\) can be derived in Fig. 11. Results in Fig. 11 show that the erosion rate is proportional to \(\delta \sqrt {\left( {l + r} \right)}\). It can be drawn from Eq. (3) that the diffusion coefficient in the steady state is equal to the slope of this curve in Fig. 11 and keeps constant with any fracture aperture. In other words, the diffusion coefficient is independent of facture aperture and thus, the erosion rate in the steady state would only increase with increasing fracture apertures and intrusion distances.

4.3 Influences of Intrusion/erosion on the Mass Loss of Specimens

According to Fig. 6 (b), the mass loss ratio of specimens by erosion could be calculated and was plotted versus time in Fig. 12. It appears in Fig. 12 that the mass loss ratio by erosion with a fracture aperture of 0.5 and 1.0 mm increased quickly but then followed by an obvious reduction in the increase rate after 15 days, which has a good agreement with that in the erosion curve (Fig. 6 (b)). Meanwhile, the evolution of mass loss ratio of specimens by intrusion with time could also be determined by the difference between total mass loss ratio of specimens (Fig. 7) and that by erosion (Fig. 12). Results in Fig. 12 show that the mass loss ratio by intrusion with a fracture aperture of 0.5 and 1.0 mm both started with a significant increase and then reached a stable value after 15 and 30 days, respectively. The turning points are consistent with that in the intrusion curve (Fig. 5 (a)). Moreover, it could also be observed in Fig. 12 that the mass loss ratios of specimens with a fracture aperture of 0.5 and 1.0 mm were mainly contributed by intrusion before 15 and 30 days, respectively. Subsequently, the specimen mass loss ratios kept on increasing and would be only dependent on the erosion rate. Indeed, as long as time for erosion is enough, the mass loss ratios of specimens by erosion may exceed that by intrusion.

According to Fig. 6 (b), the mass loss ratio of specimens by erosion after 60 days could be calculated and was plotted versus the fracture aperture in Fig. 13. Results in Fig. 13 shows that the mass loss ratio by erosion increased with increasing fracture apertures. Meanwhile, according to Figs. 8 and 13, mass loss ratio of specimens by intrusion could also be determined. Then, the relationship between mass loss ratio of specimens by intrusion and fracture aperture after 60 days was depicted in Fig. 13. It could be observed in Fig. 13 that the mass loss ratio after 60 days by intrusion increased with increasing fracture apertures. Moreover, the difference between the mass loss ratio by intrusion and erosion increased with increasing fracture apertures.

5 Conclusions

In this study, intrusion/erosion tests with a fracture aperture of 0.1, 0.5, 0.75 and 1.0 mm were conducted with a duration of 60 days. Meanwhile, in order to investigate the influence of intrusion/erosion behavior on mass loss of specimens, parallel tests with a fracture of 0.5 and 1.0 mm were repeated with a duration of 5, 15 and 30 days. After all tests stopped, the mass loss of specimens was measured. According to test results, the following conclusions could be drawn.

The intrusion distance increased with increasing fracture apertures, leading to the increase of the width of accessory-mineral ring. However, the accessory-mineral ring will in turn confine the intrusion, especially with a larger fracture aperture.

For one given fracture aperture, the erosion rate decreased significantly with time in the early period due to reduction in the diffusion coefficient by the filtration of the accessory-mineral ring. But when the erosion reached stabilization, the erosion rate increased with increasing fracture apertures and intrusion distances, irrespective of the accessory-mineral ring.

The majority of mass loss ratio of specimens was from intrusion in the early period. But when intrusion reached stabilization, the mass loss ratio of specimen will be mainly contributed by erosion. Moreover, the mass loss ratios of specimens after 60 days by intrusion and erosion both increased with increasing fracture apertures. The difference between the mass loss ratio by intrusion and erosion increased with increasing fracture apertures.

References

Bian, X., Cui, Y.J., Zeng, L.L., Li, X.Z.: State of compacted bentonite inside a fractured granite cylinder after infiltration. Appl. Clay Sci. 186, 105438 (2020)

Birgersson, M., Boergesson, L., Hedstroem, M., Karnland, O., Nilsson, U.: Bentonite erosion. Final report (No. SKB-TR-09-34). Swedish Nuclear Fuel and Waste Management Co (2009)

Cui, L.Y., Ye, W.M., Wang, Q., Chen, Y.G., Chen, B., Cui, Y.J.: Investigation on gas migration in saturated bentonite using the residual capillary pressure technique with consideration of temperature. Process Saf. Environ. Protect 125, 269–278 (2019)

Nguyen, T.S., et al.: A case study on the influence of THM coupling on the near field safety of a spent fuel repository in sparsely fractured granite. Environ. Geol. 57(6), 1239–1254 (2008)

Xu, L.B., Ye, W.M., Liu, Z.R., Wang, Q., Chen, Y.G.: Extrusion behavior of bentonite-based materials considering pore size and sand content effects. Constr. Build Mater. 347, 128580 (2022)

Luo, H.W., Ye, W.M., Wang, Q., Chen, Y.G., Chen, B.: Pore fluid chemistry effects on the swelling behavior of compacted GMZ bentonite with an artificial annular gap. Bull. Eng. Geol. Env. 80(7), 5633–5644 (2021)

Moreno, L., Liu, L., Neretnieks, I.: Erosion of sodium bentonite by flow and colloid diffusion. Phys. Chem. Earth, Parts A/B/C 36(17–18), 1600–1606 (2011)

Missana, T., Alonso, Ú., Turrero, M.J.: Generation and stability of bentonite colloids at the bentonite/granite interface of a deep geological radioactive waste repository. J. Contam. Hydrol. 61(1–4), 17–31 (2003)

Neretnieks, I., Moreno, L., Liu, L.: Clay Erosion: Impact of Flocculation and Gravitation. Svensk kärnbränslehantering AB. Swedish Nuclear Fuel and Waste Management Company (2017)

Reid, C., Lunn, R., El Mountassir, G., Tarantino, A.: A mechanism for bentonite buffer erosion in a fracture with a naturally varying aperture. Mineral. Mag. 79(6), 1485–1494 (2015)

Schatz, T., Akhanoba, N.: Bentonite buffer erosion in sloped fracture environments (No. POSIVA-2016-13). Posiva Oy (2017)

Schatz, T., et al.: Buffer erosion in dilute groundwater (No. POSIVA-12-44). Posiva Oy (2013)

Svoboda, J.: The experimental study of bentonite swelling into fissures. Clay Miner. 48(2), 383–389 (2013)

Vilks, P., Miller, N.H.: Laboratory bentonite erosion experiments in a synthetic and a natural fracture. NWMO Technical Report TR-2010-16 (2010)

Xu, L.B., Ye, W.M., Wang, Q., Chen, Y.G., Chen, B.: Investigation on intrusion of bentonite–sand mixtures in fractures with consideration of sand content andseepage effects. Bull. Eng. Geol. Environ. 81(1), 1–16 (2022)

Ye, W.M., Xu, L.B., Wang, Q., Chen, Y.G., Chen, B.: Bentonite-sand mixture intrusion process and its model in rock fissures with consideration of lateral wall friction. Chin. J. Geotech. Eng. 44(4), 613–621 (2022). (in Chinese)

Acknowledgements

The financial supports of the National Nature Science Foundation of China (42030714 and 41807237) are greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Xu, L., Ye, W., Wang, Q., Luo, H. (2023). Experimental Study on the Intrusion/Erosion Behavior of GMZ Bentonite Considering Fracture Aperture Effects. In: Liu, C. (eds) Proceedings of the 23rd Pacific Basin Nuclear Conference, Volume 1. PBNC 2022. Springer Proceedings in Physics, vol 283. Springer, Singapore. https://doi.org/10.1007/978-981-99-1023-6_74

Download citation

DOI: https://doi.org/10.1007/978-981-99-1023-6_74

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-1022-9

Online ISBN: 978-981-99-1023-6

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)