Abstract

Corrosion products in the primary circuit of Pressurized Water Reactor (PWR) during operation will cause Chalk Rivers Unidentified Deposit (CRUD), increase the level of coolant source term and deposition source term outside the core, and then affect the normal operation of PWR and the radiation field during the shutdown overhaul. Stretch-Out (SO) operation is a flexible mode of reactor, which can improve the economy of reactor. In this paper, the theoretical model of CRUD and source term analysis for PWR is introduced, and the influence of SO operation on CRUD and source term level of PWR is studied. The calculation results show that SO operation can reduce the total amount of CRUD in PWR. However, the level of coolant source term rises at the initial stage of SO operation, and the level of coolant source term can be reduced by double discharge pumps running in this case. The deposition source term outside the reactor show a gradual increasing trend. The research results provide theoretical basis and data reference for CRUD and source term level control during SO operation in PWR.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Stretch-Out (SO) operation of nuclear power plants refers to an operation mode in which positive reactivity is introduced by reducing primary coolant temperature and reactor power at the end of fuel cycle life when all control rods are at the top of the reactor and boron concentration in the primary loop is close to 0 ppm (1 ppm = 10–6), thus prolonging reactor operation time. The SO operation of nuclear power plants can not only improve the flexibility of overhaul schedule, meet the needs of refueling overhaul of group reactor units, but also increase the depth of burnup and improve the economy of plants [1].

Metallic materials in the primary circuit of Pressurized Water Reactor (PWR) will corrode and release corrosion products in the high temperature and high pressure environment, the main components of which are Ni, Fe, Cr, etc. [2, 3]. After entering the primary circuit, corrosion products migrate to all parts of the primary circuit with coolant, and deposit on the surface of fuel cladding mainly through subcooled nucleate boiling (SNB), thus forming Chalk Rivers Unidentified Deposit (CRUD) [4].

On the one hand, CRUD will adsorb boron in coolant, forming local boron enrichment on fuel assemblies, which will increase the risk of Crud Induced Power Shift (CIPS); On the other hand, the continuous increase of CRUD thickness will affect the heat transfer capacity of fuel assemblies, causing local corrosion and increasing the risk of fuel cladding failure. At the same time, metal materials will be activated under neutron irradiation to form Activated Corrosion Products (ACPs), among which the main radionuclide are 58-Co, 60-Co, 51-Cr, 54-Mn, 59-Fe, etc. ACPs are deposited on the surface of metallic material inside and outside the core, which directly affects the total radiation dose during shutdown overhaul [5]. According to statistics, about 85% of the radiation field outside the core is caused by ACPs [6]. Therefore, it is necessary to analyze the CRUD and the source terms of PWR.

In this paper, the key theoretical models of CRUD analysis and source term calculation in PWR are introduced around the main corrosion product elements (i.e. Ni, Fe, Cr) and radionuclide (i.e. 58-Co, 60-Co, 51-Cr, 54-Mn, 59-Fe). The effects of SO conditions on CRUD and source term of a PWR are obtained by analyzing and calculating under normal operating conditions and SO conditions, which provides guidance for CRUD and radiation field control under SO operation.

2 Theoretical Model

2.1 Hydrochemical Model

The hydrochemical model is used to calculate the saturated solubility of Ni, Fe and Cr in primary coolant. According to the main chemical reaction equations of these three elements in the primary circuit hydrochemical environment [7], the formulas for calculating the saturated solubility of Ni, Fe and Cr can be obtained as follows:

where: CNI, CFE and CCR represent the saturated solubility of Ni, Fe and Cr, in mol/kg; [H2] represents the concentration of dissolved hydrogen, in mol/kg; [H+] represents the concentration of hydrogen ion, in mol/kg; Ki represents the chemical equilibrium constant, which can be written as a function of temperature T, and the subscript i corresponds to different metal oxides.

2.2 CRUD Deposition Model

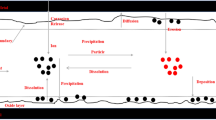

CRUD deposition model is used to calculate CRUD deposition inside and outside the core. CRUD deposition is the result of turbulent mixing and SNB mechanism, and its process can be explained based on the classical diffusion layer model [8]. Figure 1 is a schematic diagram of the diffusion layer model, and primary coolant can be divided into the bulk coolant domain and the near-wall layer near the surface of metal materials.

After the primary circuit metal material is corroded, a part of the corrosion products will form the protective oxide film, and the remaining corrosion products will be released into the coolant in the form of ion and particulate, and then enter the near-wall layer from the bulk coolant domain by diffusion. After reaching a certain concentration in the near-wall layer, they will deposit on the surface of the protective oxide film, and form CRUD in a turbulent way. At the same time, SNB will occur on the surface of fuel rods, forming a stable steam channel, and corrosion products will deposit around the steam channel, finally forming CRUD with dense bottom and loose porous in the near-wall layer. The mass transfer process is shown in Fig. 1.

Based on the above mechanism, the deposition of corrosion products in the coolant can be regarded as the result of turbulent mixing and SNB, so the deposition rate per unit area of CRUD is:

where: wi represents the deposition rate, in g/(cm2·s); ṁe represents the SNB rate, in g/(cm2·s); kb and kw represents the deposition coefficients from the bulk coolant domain to the near-wall layer and from the near-wall layer to the fuel surface, respectively, which can be calculated by Chilton-Colburn [9] formula, in g/(cm2·s); Ci and Ci0 represent the solubility of corrosion products in the bulk coolant domain and fuel surface respectively, which need to be obtained according to Gibbs’ law and data fitting of solubility experiment in the primary circuit environment of PWR [10,11,12,13,14,15,16], in g/g; i corresponds to three elements: Ni, Fe and Cr.

2.3 Source Term Model

The source term model is used to calculate the radioactivity level distribution of coolant and nuclide inside and outside the reactor.

The corrosion product particles and ion released from the base metal in the primary circuit circulate with the coolant. When the corrosion products flow through the core area, some of them will be irradiated by neutron to become activated corrosion products, forming coolant source term. On the other hand, corrosion products may be deposited when they flow in the circuit, and the CRUD deposition on the fuel surface forms the deposition source term inside the core, while the deposition outside the core forms the deposition source term outside the core.

The formula of activity concentration of activated corrosion products in primary coolant is as follows:

where: Ci(t) represents the specific activity mass of radionuclide i in coolant, in Bq/t; mw represents the mass of primary coolant, in t; λi represents the decay constant of nuclide, in s−1; Pi represents the generation rate of nuclide i, in Bq/s. Ci (t) and Pi are related to decay constant of nuclide, nucleon neutron of parent core in coolant, neutron neutron rate in core area, microscopic reaction cross section, ratio of fluid flow time in core to total flow time inside and outside the core, and axial power share of control body.

The deposition source term inside the core mainly considers the surface of fuel assemblies, and the formula of activity concentration of the deposition source term inside the core is as follows:

where: Ci(t)in represents the area specific activity of nuclide i inside the core, in Bq/cm2; Ad represents the deposition area, in cm2; λi represents the decay constant of nuclide, in s−1; P’i represents the formation rate of nuclide i in CRUD inside the core, in Bq/s; Ci (t) in and P’i are related to decay constant in nuclide, nucleon neutron in the parent core of CRUD inside the core, neutron rate in the core area, microscopic reaction cross section, axial power share of control body, CRUD thickness inside the core and deposition area.

The deposition of corrosion products outside the core is mainly considered in the main pipeline, Steam Generator (SG) heat transfer tube, lower chamber, and primary pumps. The deposition rate is different at positions with different fluid velocity and temperature. The formula of activity concentration of the deposition source term outside the core is as follows:

where: Ci(t)out represents the area specific activity of nuclide i outside the core, in Bq/cm2; Di(t) represents the radioactivity generation rate caused by CRUD deposition outside the core, in Bq/(cm2 · s); λi represents the decay constant of nuclide, in s−1; Ci(t)out and Di(t) are related to the decay constant in nuclide, the deposition rate of corrosion products, and the proportion of nuclide isotopes in all isotopes.

2.4 Mass Conservation of Corrosion Products in Primary Circuit

Regardless of the element changes caused by activation, the corrosion products of metal materials are released into the coolant, and the following mass transfer processes will occur:

-

1)

CRUD inside and outside the core is deposited on the fuel surface and the surface of the primary circuit structural material;

-

2)

CRUD inside and outside the core will be slowly released after deposition and return to the primary coolant again;

-

3)

Some of the corrosion products that have not been deposited are purified by the chemistry and volume control system, and some remain in the coolant.

Based on the mass conservation equation:

where: Mbulk represents the water loading capacity of the primary circuit; C represents the concentration change rate of corrosion products in the primary circuit; ΔmIC represents the rate of mass change of CRUD inside the core; ΔmOC represents the rate of mass change of CRUD outside the core; ΔmCVCS represents the rate of mass change of corrosion products purified by the chemical and volume control system; ΔmREL represents the rate of mass change of CRUD release.

3 Calculation Results and Analysis

3.1 Input Parameters

Based on the above model, CAMPSIS software independently developed by China Nuclear Power Technology Research Institute [17] is used to analyze the normal operation and SO conditions of a PWR continuous fuel cycle. The letdown system can purify primary coolant, reduce CRUD deposition inside and outside the core, and reduce coolant source term and deposition source term. There is only one letdown pump in normal operation. In the analysis, by increasing flow rate, the influence of double letdown pumps operation on CRUD and source term is obtained. Thermal hydraulic parameters for calculations are provided by sub-channel software LINDEN [18].

3.2 Discussion on Calculation Results

Figure 2 shows the total CRUD in different operation modes of the PWR, and Fig. 3 shows the CRUD mass distribution in each operation mode in the primary circuit. The calculation results show that:

-

1)

Under normal operating conditions, the total amount of CRUD deposition is gradually increased with the operating time in a fuel cycle; However, during SO, the total amount of CRUD decreases, which is due to the decrease of the output power and temperature of the primary circuit, the decrease of SNB rate reduces the total amount of CRUD deposition caused by boiling. However, with the increase of fuel cycle, the oxide film on the surface of the primary circuit structure materials becomes more and more stable, and the corrosion products released into the primary circuit become less and less, and the total amount of CRUD shows a gradual downward trend.

-

2)

In the primary circuit, the total amount of CRUD inside the core is more than half of the total amount of CRUD in primary circuit and the mass removed by letdown. Under the condition of double letdown pumps operation, the total amount of CRUD removed by letdown accounts for about 23% of the total CRUD mass while under normal operation conditions, it is only about 14%, which efficiently reduces the total amount of CRUD deposited inside and outside the core.

-

3)

Under the double letdown pumps operation condition, because of the increase of letdown flow rate, the purification efficiency is improved, and the total amount of corrosion products in the primary circuit is reduced, so the total amount of CRUD deposition is also reduced. With the increase of fuel cycle, the total CRUD of double letdown pumps decreased continuously. Compared with single letdown pump operation condition, the CRUD decreased by about 18% at the end of the fourth fuel cycle.

Figure 4 and Fig. 5 show the coolant source term levels of 58-Co and 60-Co respectively, and 51-Cr, 54-Mn and 59-Fe have similar trends, which are not listed here. Figure 6 shows the deposition source term level at the main pipeline outside the reactor. The calculation results show that:

-

1)

The source term level of radionuclide is determined by its generation rate and disintegration rate, and the disintegration rate is related to the half-life time of nuclide. The coolant source terms of 58-Co and 60-Co generally show a decreasing trend with the fuel cycle. However, during SO, the source term level of coolant rises, which is due to the fact that part of CRUD returns to the primary circuit due to temperature drop at this stage, resulting in an increase in the source term level of coolant. At this time, the source term level of coolant can be reduced by running the double letdown pumps.

-

2)

With the fuel cycle, the deposition source term of the main pipeline outside the reactor gradually increases, which is due to the fact that some radionuclide with long half-life, such as 60-Co, form a relatively stable CRUD structure after deposition on the main pipeline, which is difficult to return to the primary circuit, so the deposition source term will become larger and larger. According to the operation experience, the radioactivity such as 58-Co and 60-Co can be replaced from the CRUD by adding Zinc in the primary circuit, and then the deposition source term level can be reduced by letdown purification circuit [2, 19].

4 Conclusion

In this paper, the effects of SO conditions on CRUD, coolant source term and deposition source term of a PWR are analyzed. The main conclusions are as follows:

-

1)

During SO, the total amount of CRUD can be reduced while the economy is improved, and the total amount of CRUD inside and outside the core can be further reduced by double letdown pumps operation;

-

2)

At the initial stage of SO, the coolant source term level will increase, and at this time, the coolant source term level can be reduced by running double letdown pumps;

-

3)

The deposition source term level of the main pipeline outside the core increases with the running time.

References

Yin, L., Wu, D., Shen, Z.X., et al.: Special study on stretch-out operation of M310 PWR. Sci. Technol. Innovat. Herald 8, 47–48, 50 (2020). (in Chinese)

Deshon, J.: PWR Axial Offset Anomaly (AOA) Guidelines. EPRI Technical Report, 1008102 (2004)

Riess, R.: Chemistry Experience in the Primary Heat Transfer Circuit of Kraftwerk Union Pressurized Water Reactors. Nuclear Technology, Taylor & Francis Group, pp. 153–159 (2017)

Meng, S.Q., Hu, Y.S., Li, C.Y., et al.: A CIPS risk evaluation methodology applicable for PWR. Nucl. Techniq. 44(09), 86–91 (2021). (in Chinese)

Li, L.: Research on model of activation and migration of corrosion products in the primary loop of water-cooled reactor. School Nucl. Sci. Eng. (2017). (in Chinese)

Xu, M.X.: Primary coolant activation corrosion products cobalt/silver/antimony in PWR. Nucl. Safety 1, 1–9 (2012). (in Chinese)

Meng, S.Q., Hu, Y.S., Yan, Y.L., et al.: Research of thermal hydraulic conditions effect on PWR CIPS risk. Front. Energy Res. Nucl. Energy (2022)

Kang, S., Sejvar, J.: The CORA-II Model of PWR Corrosion-Product Transport. EPRI Technical Report (1985)

Bird, R.B., Stewart, W.E., Lightfoot, E.N.: Transport Pheomena, 2nd Edn. Department of Chemical Engineering, University of Wisconsin (2002)

Speight, J.G.: Lange’s Handbook of Chemistry, 16th edn. The McGraw-Hill Companies (2005)

Rummery, T.E., Macdonald, D.D.: Prediction of corrosion product stability in high temperature aqueous systems. J. Nucl. Mater. 55(1), 23–32 (1975)

Chen, C.M., Aral, K., Theus, G.J.: Computer-Calculated Potential pH Diagrams to 300 ℃. EPRI Technical Report, EPRI-NP--3137-Vol. 3 (1983)

Beverskog, B., Puigdomenech, I.: Revised pourbaix diagrams for chromium at 25–300 ℃. Corros. Sci. 39(1), 43–57 (1997)

Beverskog, B., Puigdomenech, I.: Revised pourbaix diagrams for iron at 25–300 °C. Corros. Sci. 38(12), 2121–2135 (1996)

Beverskog, B., Puigdomenech, I.: Revised pourbaix diagrams for nickel at 25–300 ℃. Corros. Sci. 39(5), 969–980 (1997)

Huang, J., Wu, X., Han, E.H.: Influence of pH on electrochemical properties of passive films formed on alloy 690 in high temperature aqueous environments. Corros. Sci. 51(12), 2976–2982 (2009)

China General Power Technology Research Institute. China General Nuclear Power Group, CGN Power. PWR Fuel Crud Behavior Analysis Code [Abbreviation: CAMPSIS]V1.0. China: 2021SR0623899 (2021)

China General Power Technology Research Institute. China General Nuclear Power Group, CGN Power. Sub-channel Analysis Code for Reactor Core [Abbreviation: LINDEN]V1.4. China: 2018SR517526 (2017)

Haas, C.: Pressurized water reactor zinc application: 2010 industry zinc update report. EPRI Technical Report, 1021184 (2010)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Ruan, T., Mao, Y. (2023). Study on the Influence of Stretch-Out Operation on the Deposition of Corrosion Products and Source Term Level in the Primary Circuit of Pressurized Water Reactor. In: Liu, C. (eds) Proceedings of the 23rd Pacific Basin Nuclear Conference, Volume 1. PBNC 2022. Springer Proceedings in Physics, vol 283. Springer, Singapore. https://doi.org/10.1007/978-981-99-1023-6_7

Download citation

DOI: https://doi.org/10.1007/978-981-99-1023-6_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-1022-9

Online ISBN: 978-981-99-1023-6

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)